Greening method for stepped mine

A stepped, mine-based technology, applied in the field of mine greening, can solve problems such as no greening, poor greening repair effect, etc., achieve low operation difficulty coefficient and reduce soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

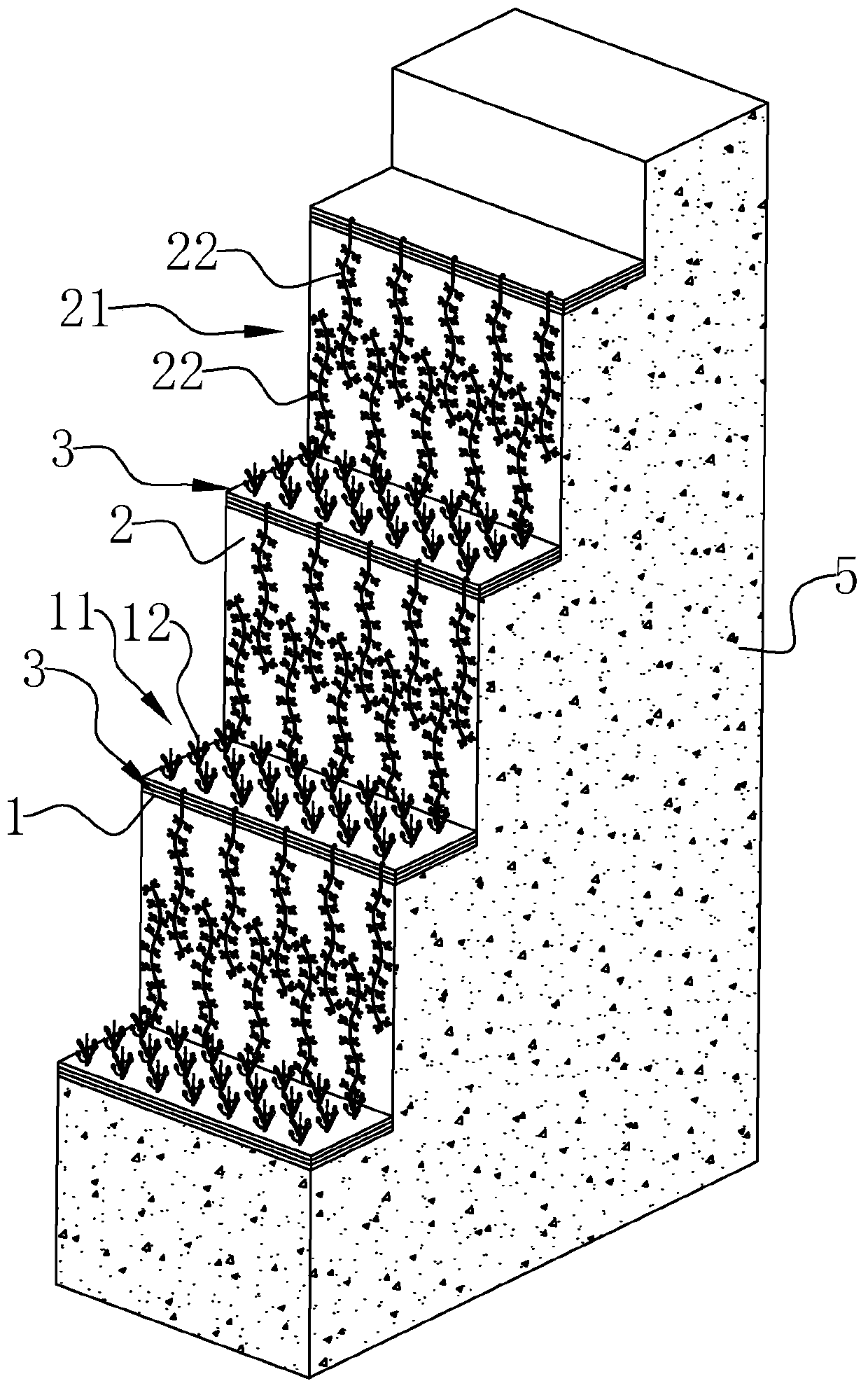

[0041] The invention discloses a greening method for stepped mines, such as figure 1 shown, including the following steps:

[0042] When mining, move the soil material of the original soil layer on the surface of the mine to a position 500 meters away from the construction ground. After the mining is over, do the following work:

[0043]S1: Use the soil transport layer to transport the soil material of the original soil layer on the surface of the mine to the greening area, and then spread the soil material of the original soil layer on the surface of the mine on the horizontal terrace 1, thereby forming a 1m-thick layer on the horizontal terrace 1 Planting the soil layer 3, and then laying gravel (not shown in the figure) at the position where the planting soil layer 3 is located outside the horizontal terrace 1 to reduce soil erosion;

[0044] S2: plant seedlings 12 in the position where the planting soil layer 3 is far away from the inner and outer end walls of the horizon...

Embodiment 2

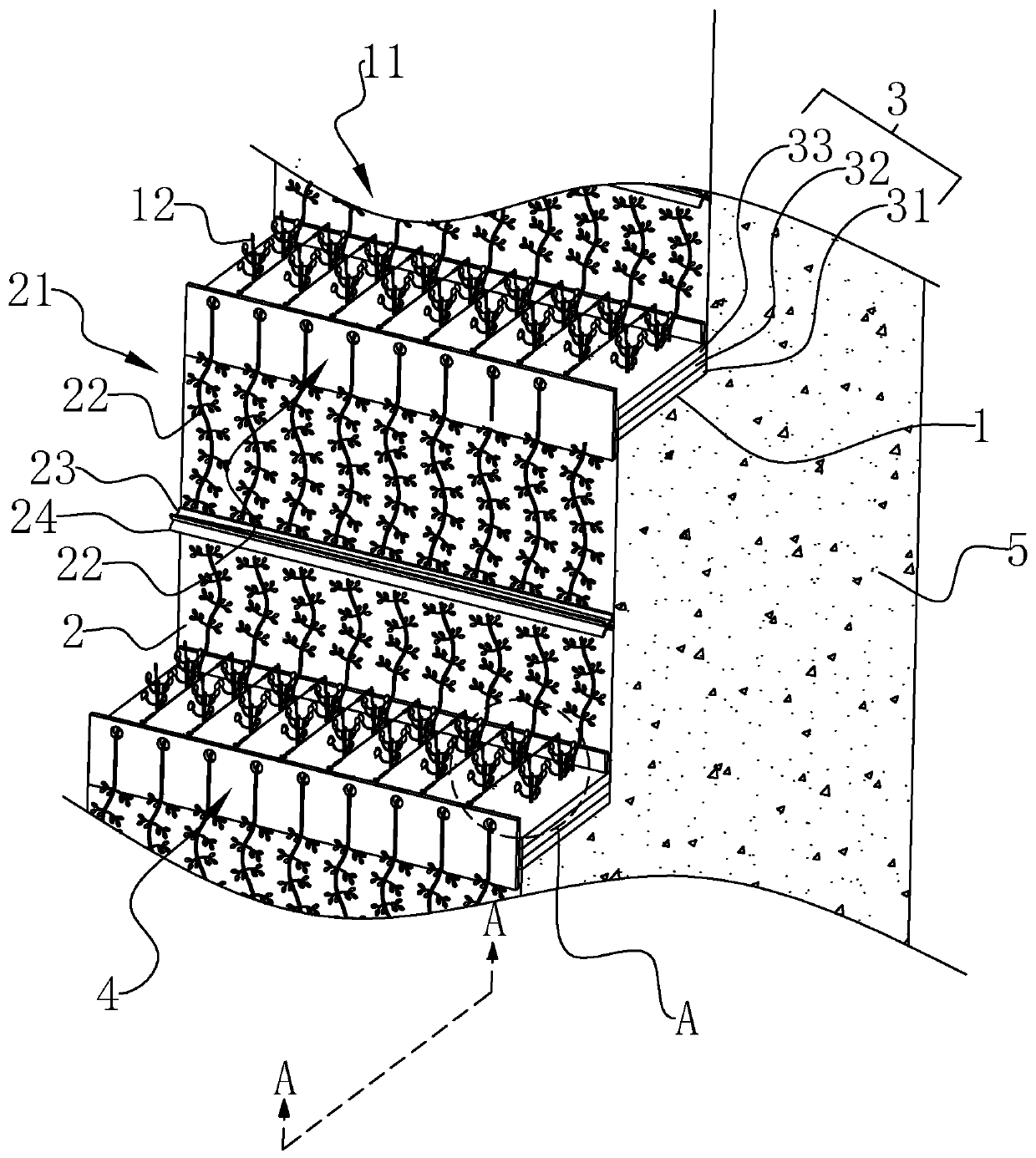

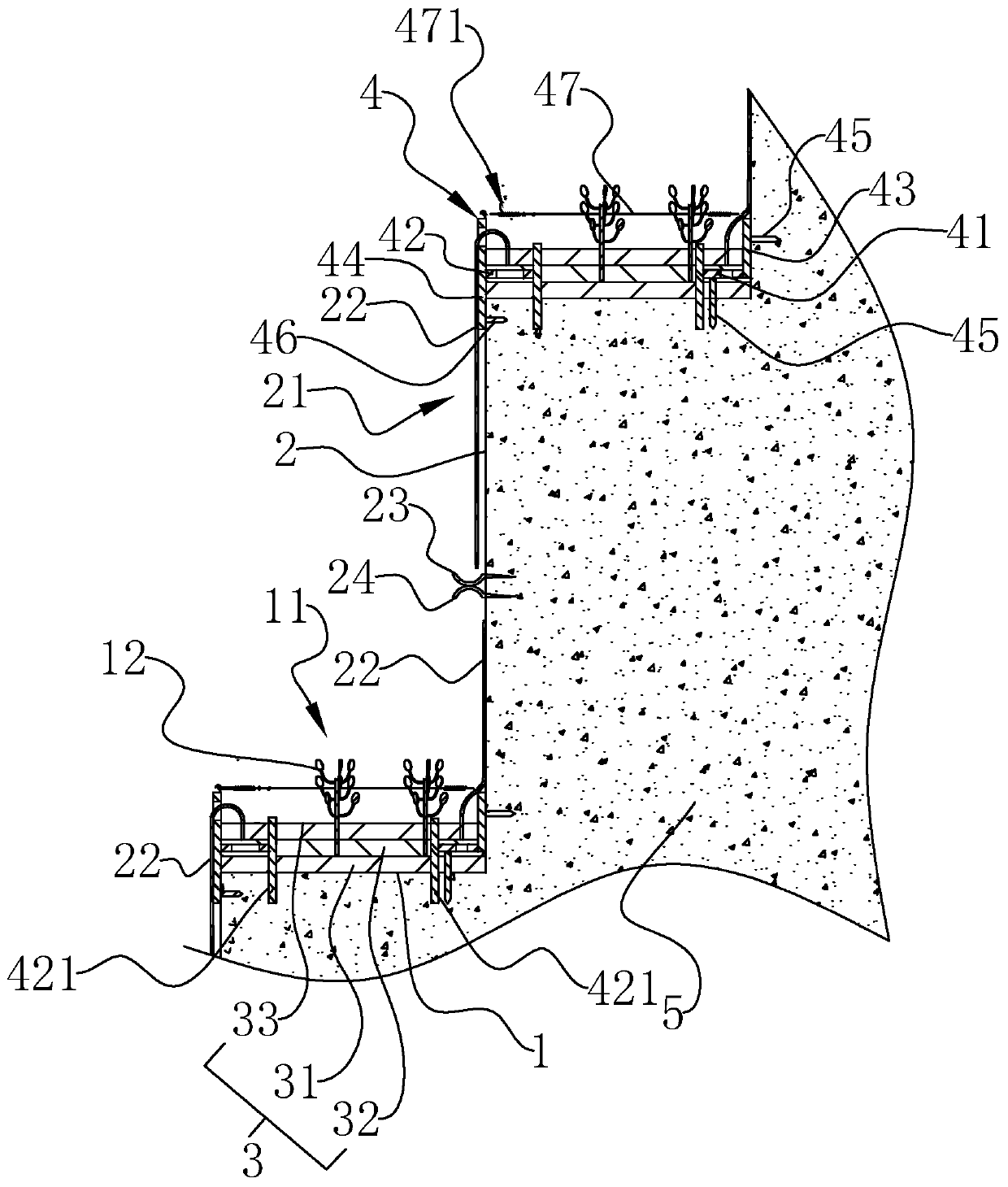

[0048] A greening method for stepped mines, such as figure 2 and image 3 Shown, the difference between embodiment two and embodiment one is: planting soil layer 3 comprises base layer 31, planting middle layer 32 and cover surface layer 33 successively from bottom to top; The soil material of the original soil layer is mixed, and the middle layer 32 of the planting is the soil material of the original soil layer of the mine, and the covering surface layer 33 is crushed stones; One deck of crushed stones and the original soil layer soil material mixture of the mine form the thick base layer 31 of 30cm; Then, a layer of original soil layer soil material of the mine is laid on the base layer 31 to form a 90cm thick planting middle layer 32, and then plant the middle layer Plant seedlings 12 and vines 22 in 32; Plant a layer of crushed stones on the surface of the middle layer 32 at last to form a 10cm thick covering surface 33; Soil-fixing components 4 are provided to reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com