Combined anti-seepage body for solid waste pile pollution prevention and ecological restoration

A technology for pollution prevention and ecological restoration, applied to waterway systems, buildings, water supply devices, etc., can solve problems such as complex construction procedures, long construction periods, and poor anti-seepage effects, and achieve good vertical anti-seepage effects, convenient construction, and cost savings The effect of land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further describe the present invention, a combined anti-seepage body for solid waste pile pollution prevention and ecological restoration according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

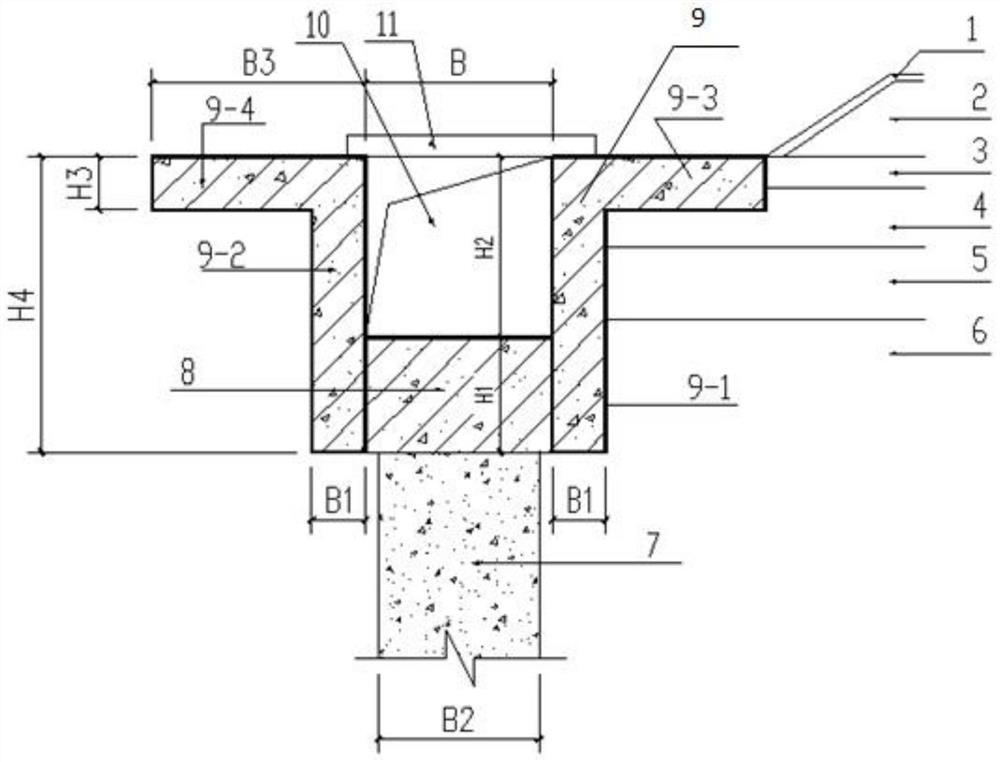

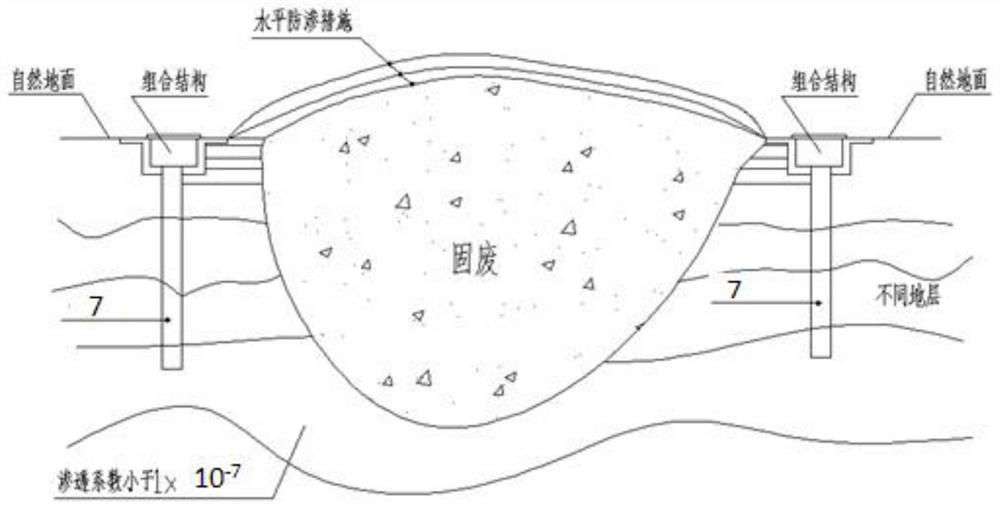

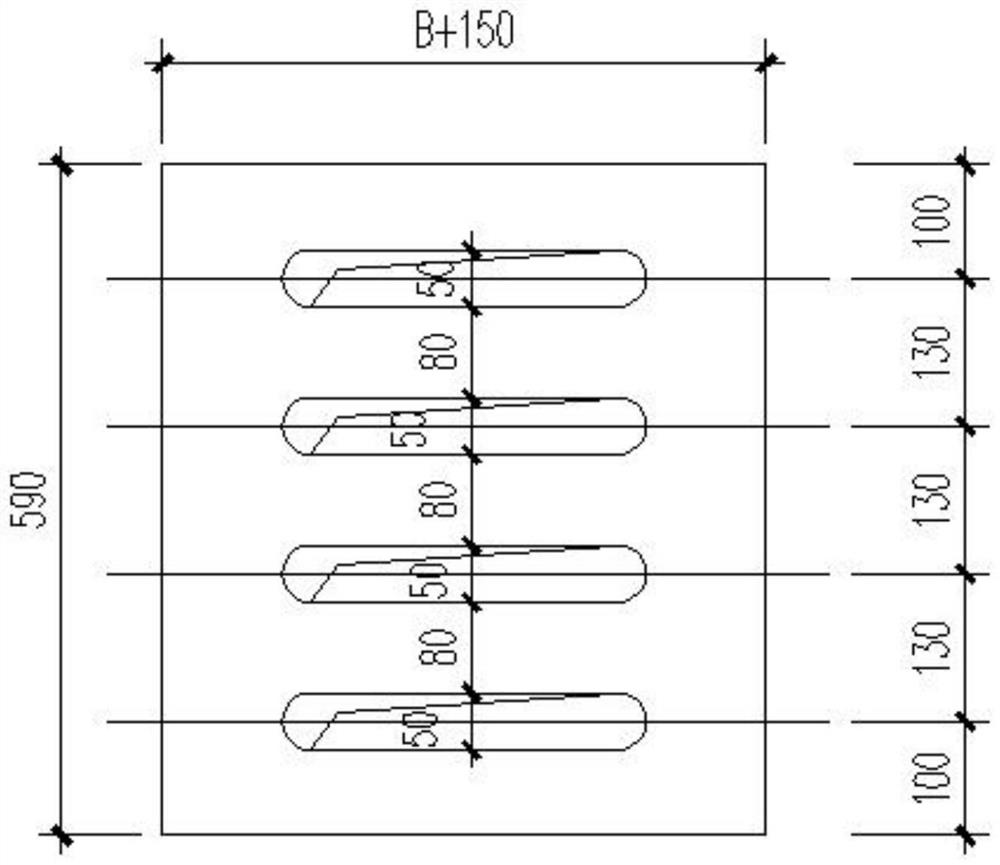

[0027] Depend on figure 1 Shown is a combined anti-seepage body structure sectional view of the present invention for solid waste heap pollution prevention and ecological restoration and combined figure 2 , image 3 It can be seen that a combined anti-seepage body used for solid waste pile pollution prevention and ecological restoration in the present invention is composed of a vertical anti-seepage wall 7, a composite anti-seepage engineering structure 9, a horizontal anti-seepage system, and a horizontal cover plate 11; The composite anti-seepage engineering structure 9 described above is composed of a vertical anti-seepage inner wall 9-1 and an inner wall covering plate 9-3 extending from its u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com