Fermented pastry blank preparation device

A technology for preparing equipment and blanks, which is applied to dough fermenters, baking, household appliances, etc. It can solve the problems of not being able to meet the needs of fermented pastry blank preparation, not being able to use small household devices, and finely divided functions, so as to reduce the size of the device. The effect of volume, reducing the number of use, and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to clearly illustrate the technical characteristics of this solution, the following describes the solution through specific implementations.

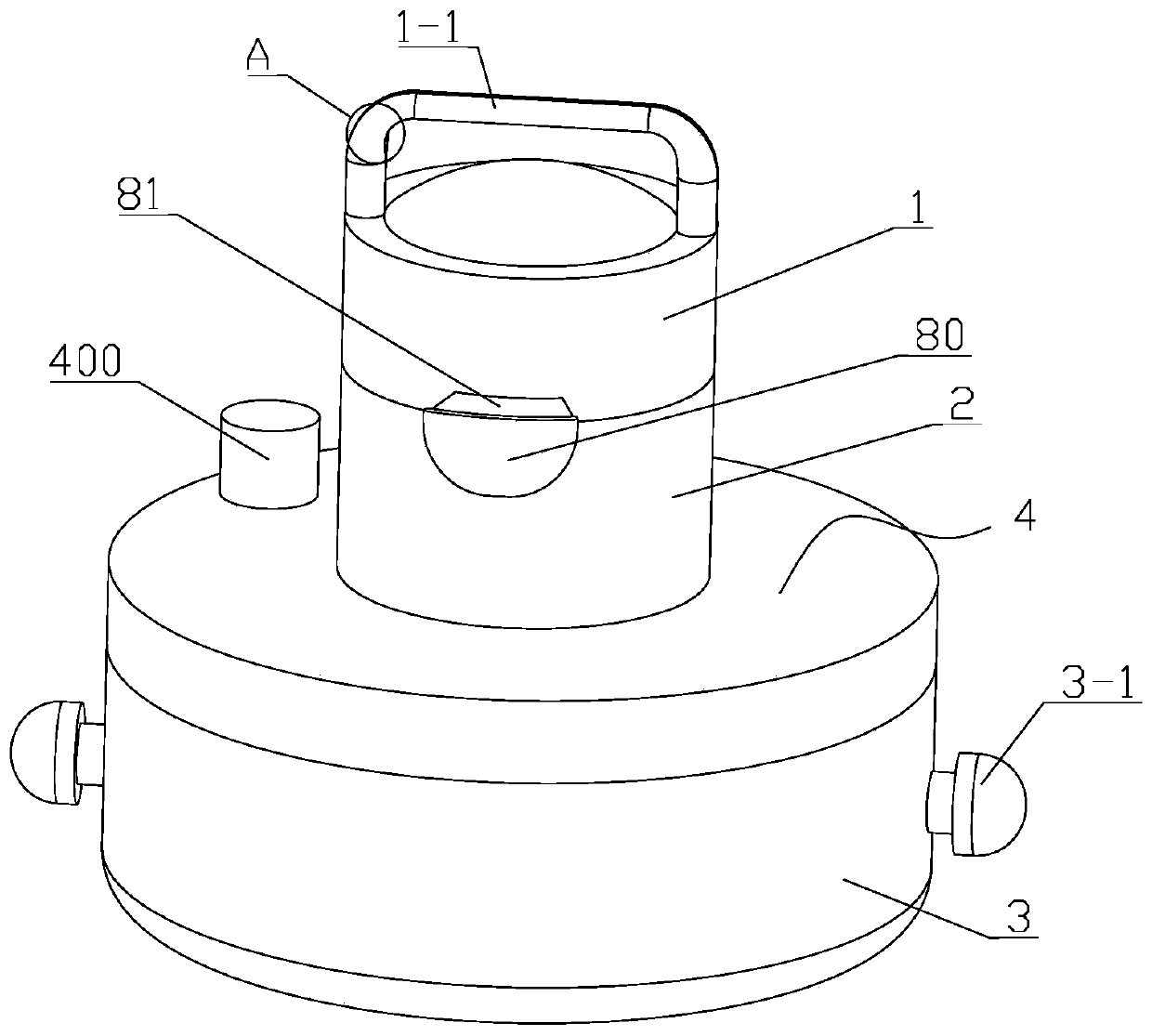

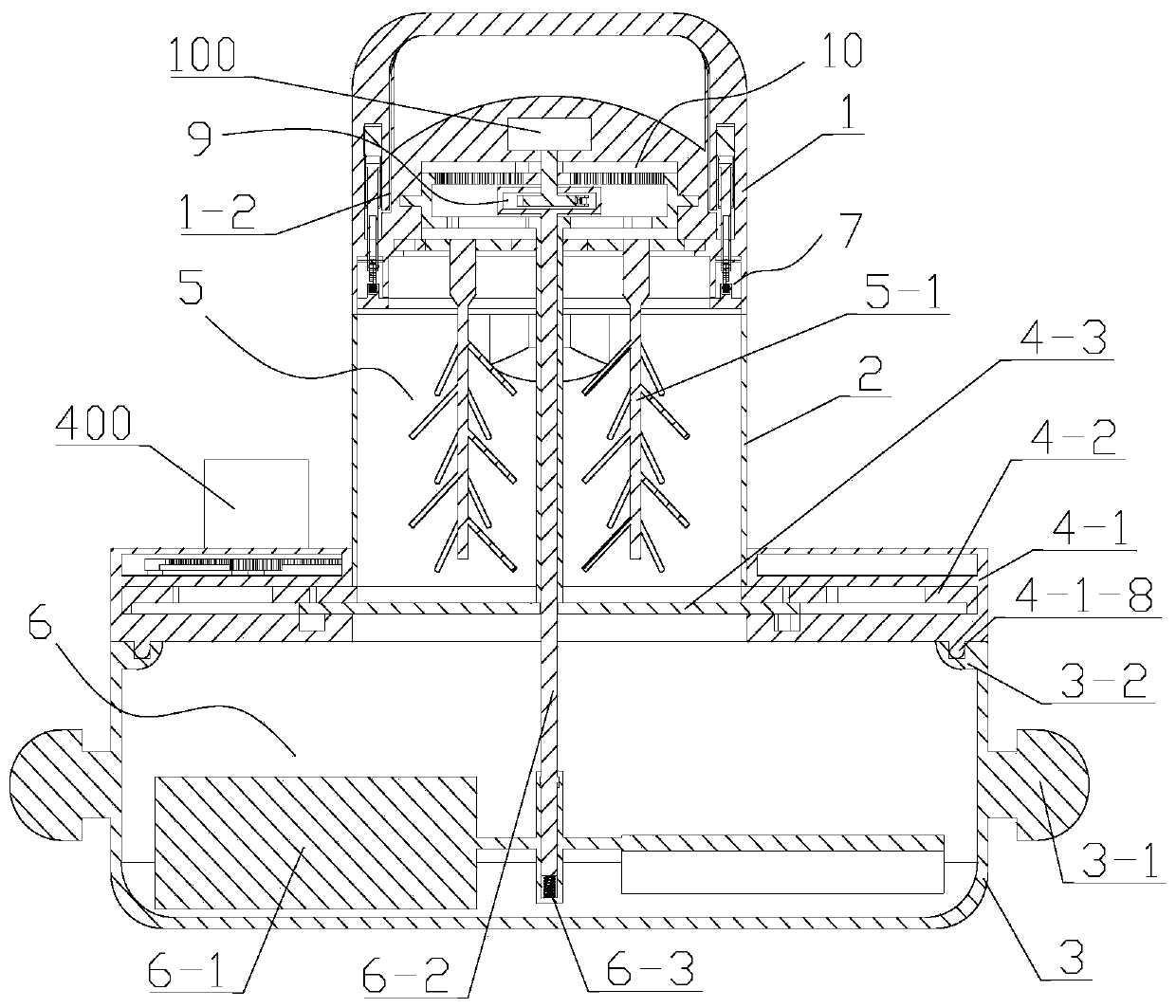

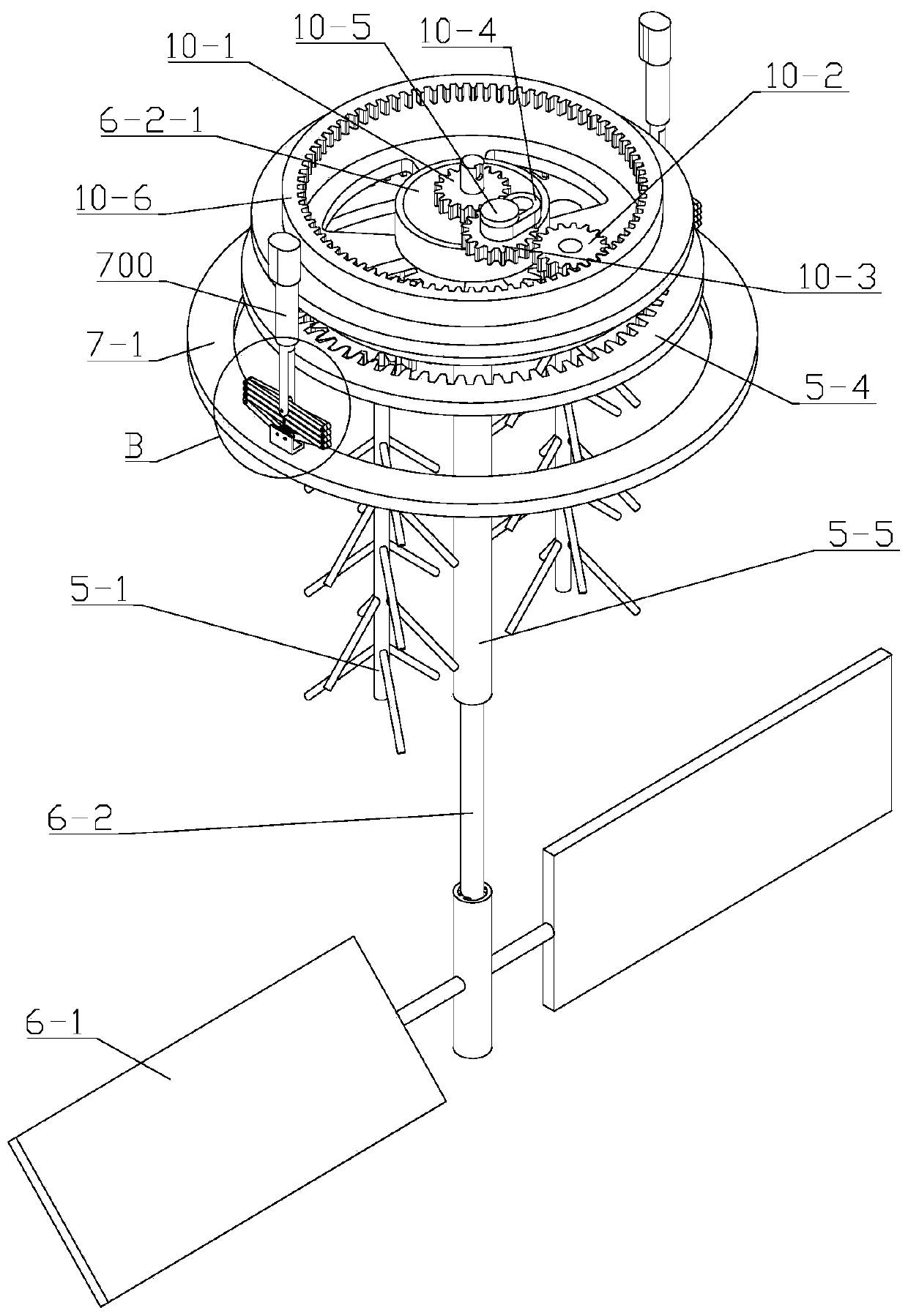

[0079] See Figure 1 to Figure 17 , The present invention is: a fermented pastry blank preparation device, which includes a top cover 1, a stirring chamber 2, a connecting valve 4, and a turning chamber 3, which are arranged in a collinear centerline from top to bottom, and a stirring chamber 2 The feeding unit with the inner cavity connected, the upper end is set on the top cover 1, the lower end acts on the stirring unit 5 in the inner cavity of the mixing chamber 2, the upper end is set on the top cover 1, and the lower end acts on the mixing chamber 3 The mixing unit 6 of the cavity, and the control unit set on the top cover 1 to control the mixing unit 5 and the mixing unit 6 respectively; the top cover 1 and the mixing chamber 2 can be detachably connected to facilitate the operation of the mixing chamber 2 and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com