Cartilage defect repair module and method for forming same

A cartilage repair and cartilage technology, which is applied in the medical field to achieve the effects of weight-bearing, reliable effect and making up for insufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

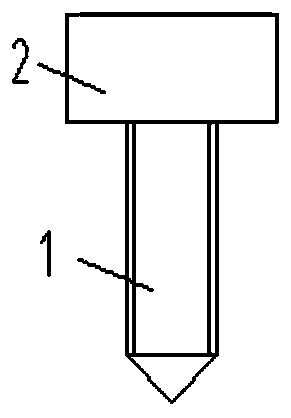

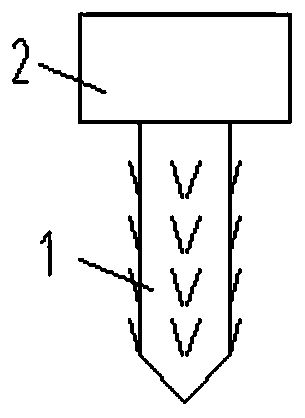

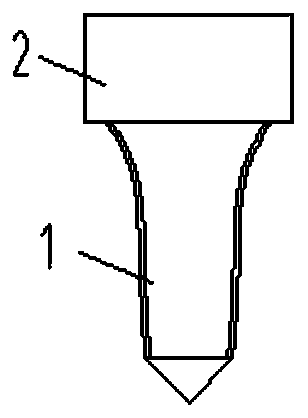

[0040] Such as Figure 5 Shown is a flowchart of a method for forming a module for repairing a cartilage defect provided by the present invention. As can be seen from the figure, the method includes:

[0041] Obtain the mechanical parameters of normal cartilage;

[0042] Establishing a virtual model of the module for cartilage repair according to the mechanical parameters of normal cartilage;

[0043] Using the 3D printing method and the virtual model, a repairing module matching the cartilage defect to be repaired is formed.

[0044] Wherein, the mechanical parameters of normal cartilage include strength and elastic modulus of normal cartilage. The above-mentioned parameters of normal cartilage are the average normal parameters of human cartilage tissue, and are obtained based on the measurement of a large number of normal cartilages that need surgery for various reasons. According to the mechanical parameters of normal cartilage, establishing a virtual model of the module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com