Sewage floating object cleaning equipment

A technology for cleaning equipment and floating objects, which is applied in the direction of filtration and separation, separation methods, fixed filter elements, etc., can solve the problems of unable to clean sediments and salvage floating objects, and achieve reduced floor space, large volume, and reduced The effect of maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

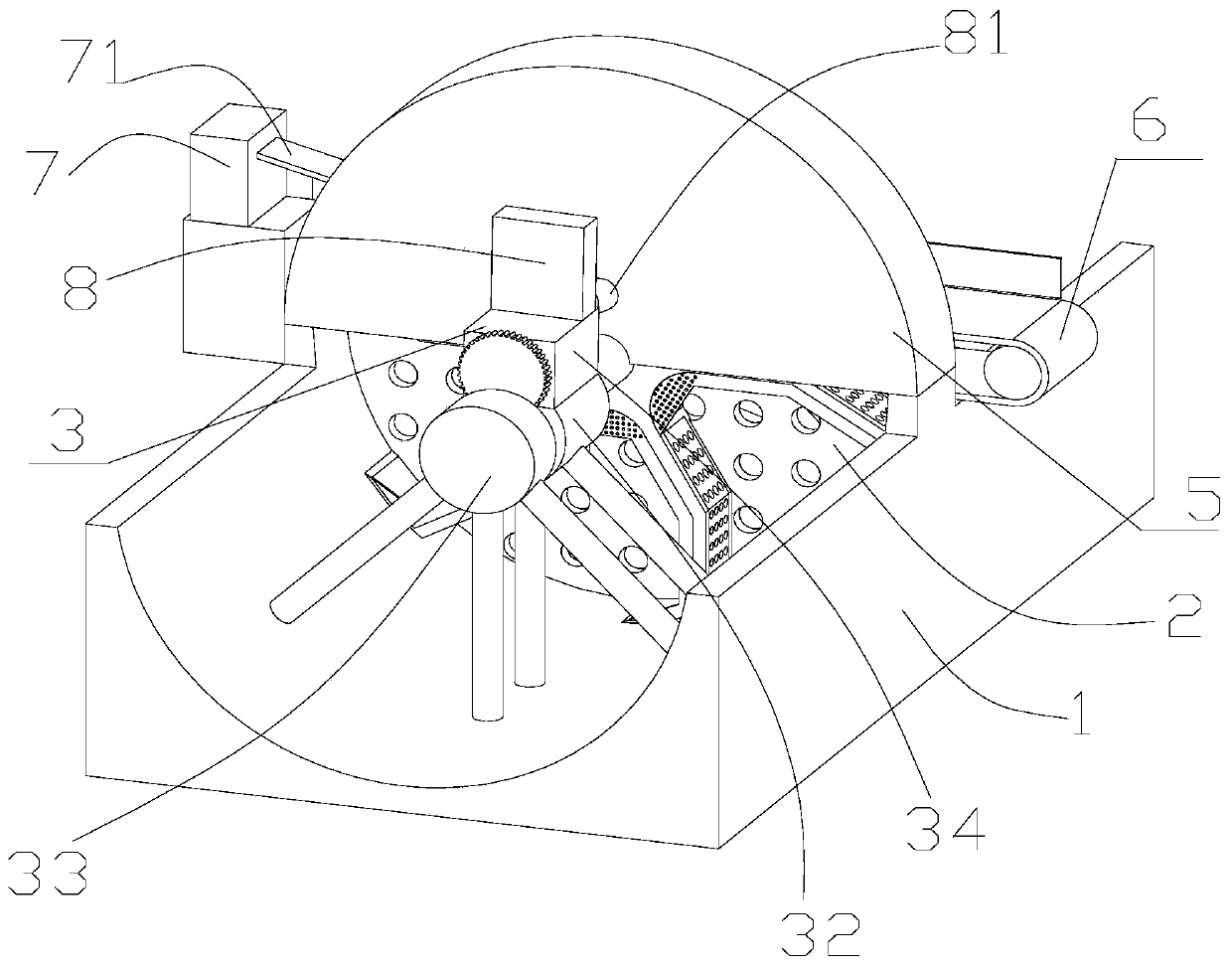

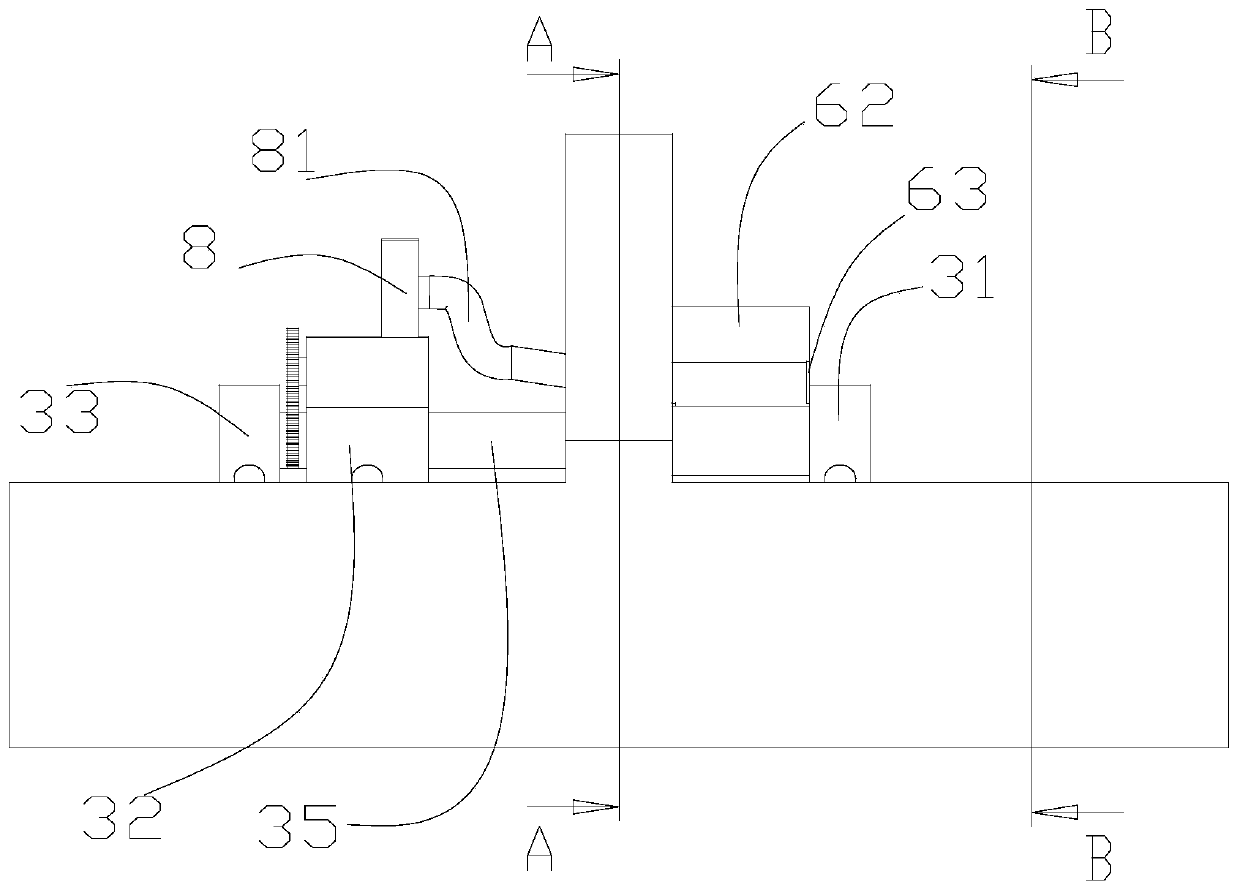

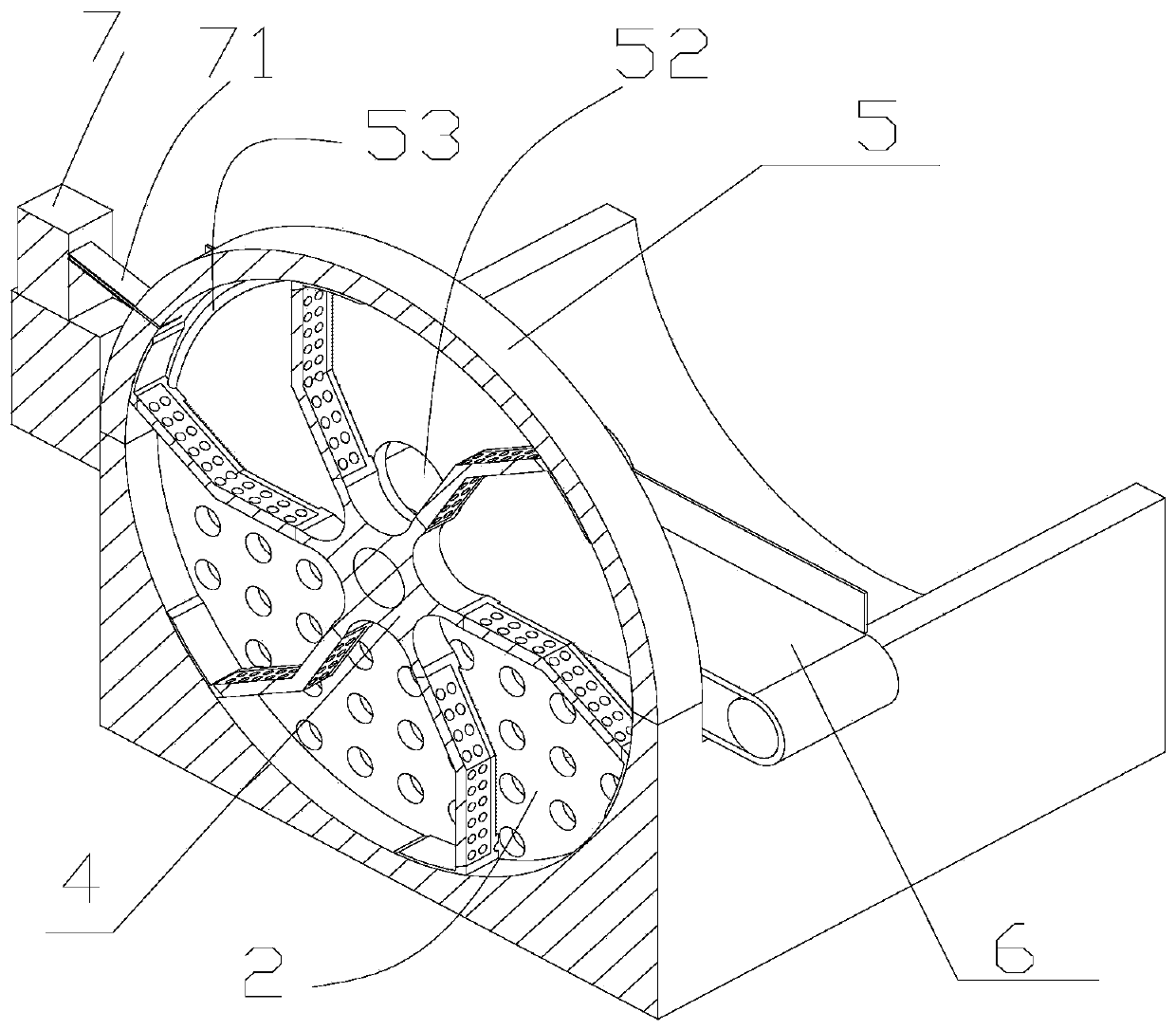

[0028] Such as Figure 1-9 As shown, a sewage floating object cleaning equipment, a sewage floating object cleaning equipment, includes a sewage pipeline 1, a filter plate 2, a transmission assembly 3, a hook-shaped fan blade 4, a casing 5 and a conveyor belt assembly 6; the sewage pipeline 1. The inner wall is in the shape of a circular arc, and the length can be extended. One end is the sewage inlet, and the other end is the sewage outlet, which leads to the fine grid. The filter plate 2 is available in the market and can filter branches, leaves, plastic bags, etc. Floaters and suspended objects, the hook-shaped fan blade 4 includes a central piece 41, a fan plate 42, a claw 44, a water hole 43 and a chute 47; the central piece 41 is hexagonal, and the central piece 41 The positions of the 6 corners of the center piece are respectively fixedly connected to one end of the 6 fan plates 42, and the positions of the 6 sides of the central piece 41 are provided with the chute 47,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com