High-precision cutting device for stainless steel coil for constructional engineering

A technology for construction engineering and cutting devices, which is applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of uncontrollable cutting length, affecting the subsequent use of steel coils, and damage to steel coils, so as to achieve a good cutting environment and improve Cutting efficiency, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

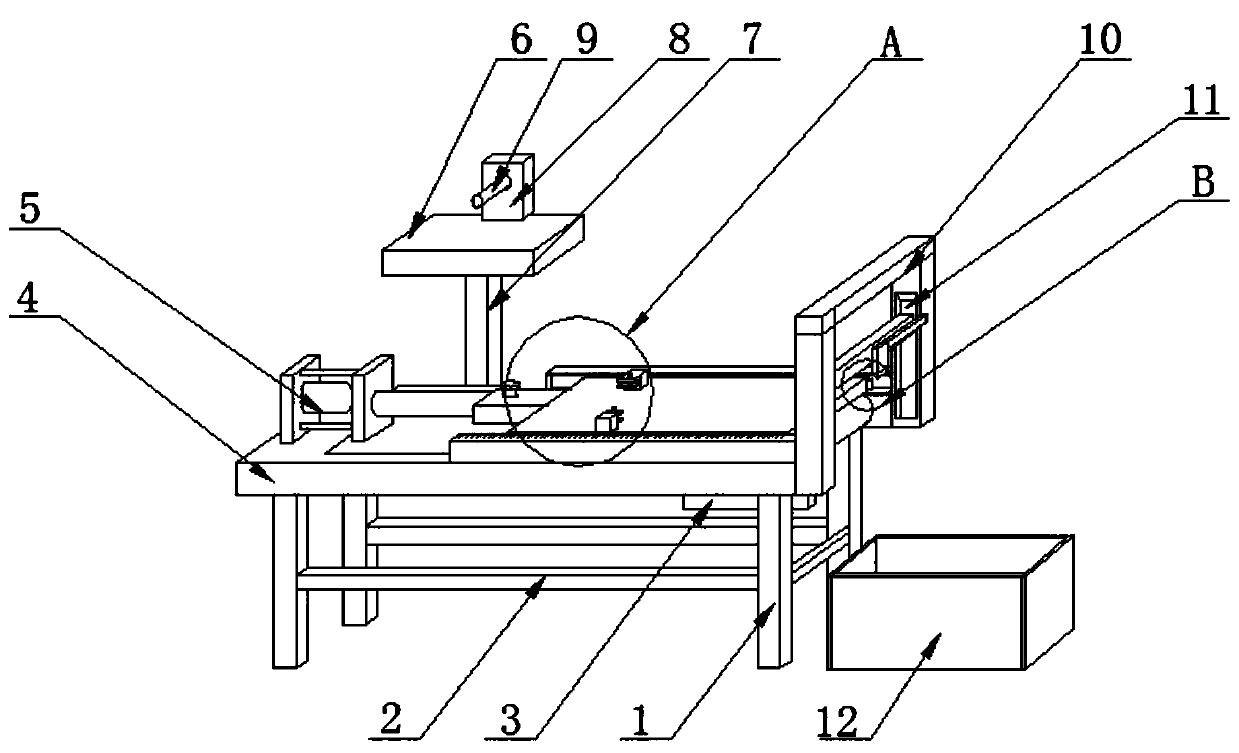

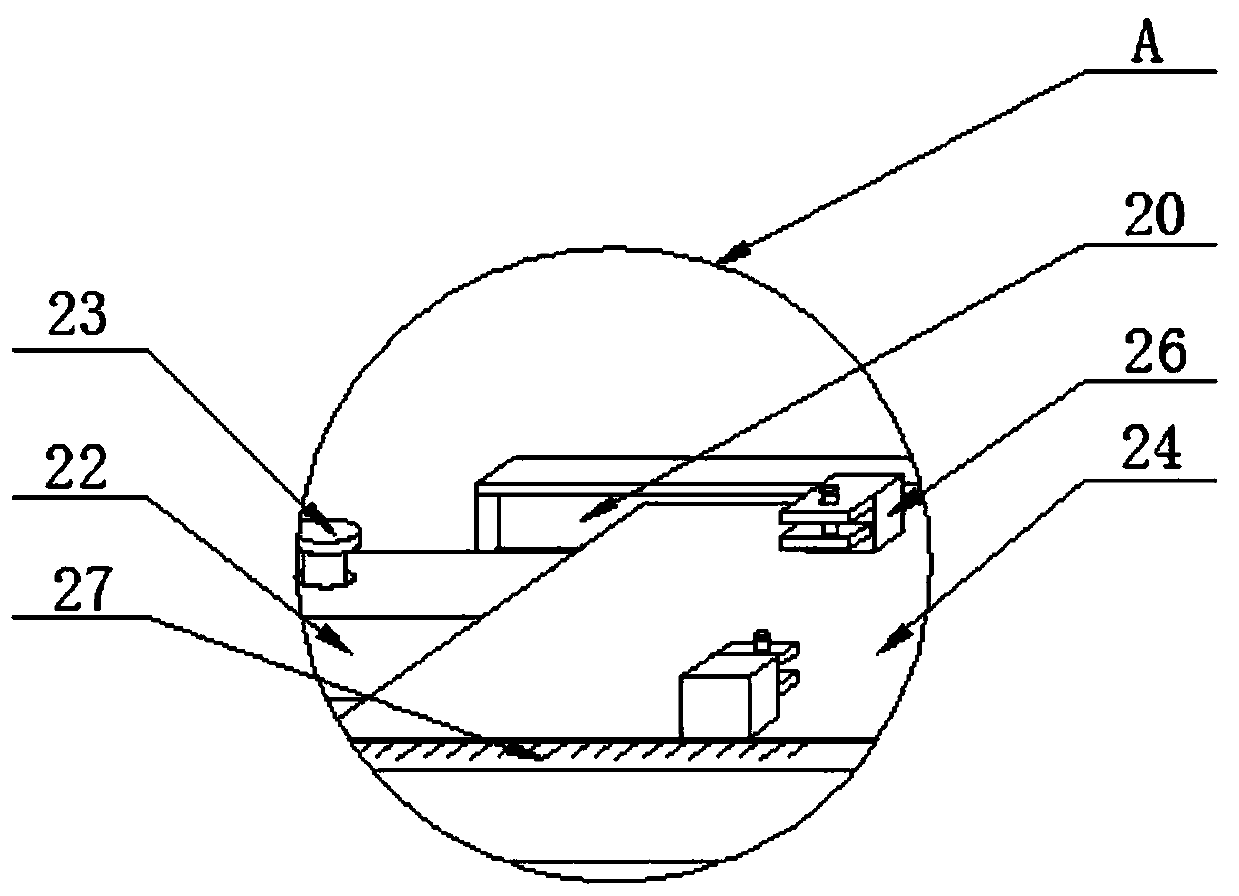

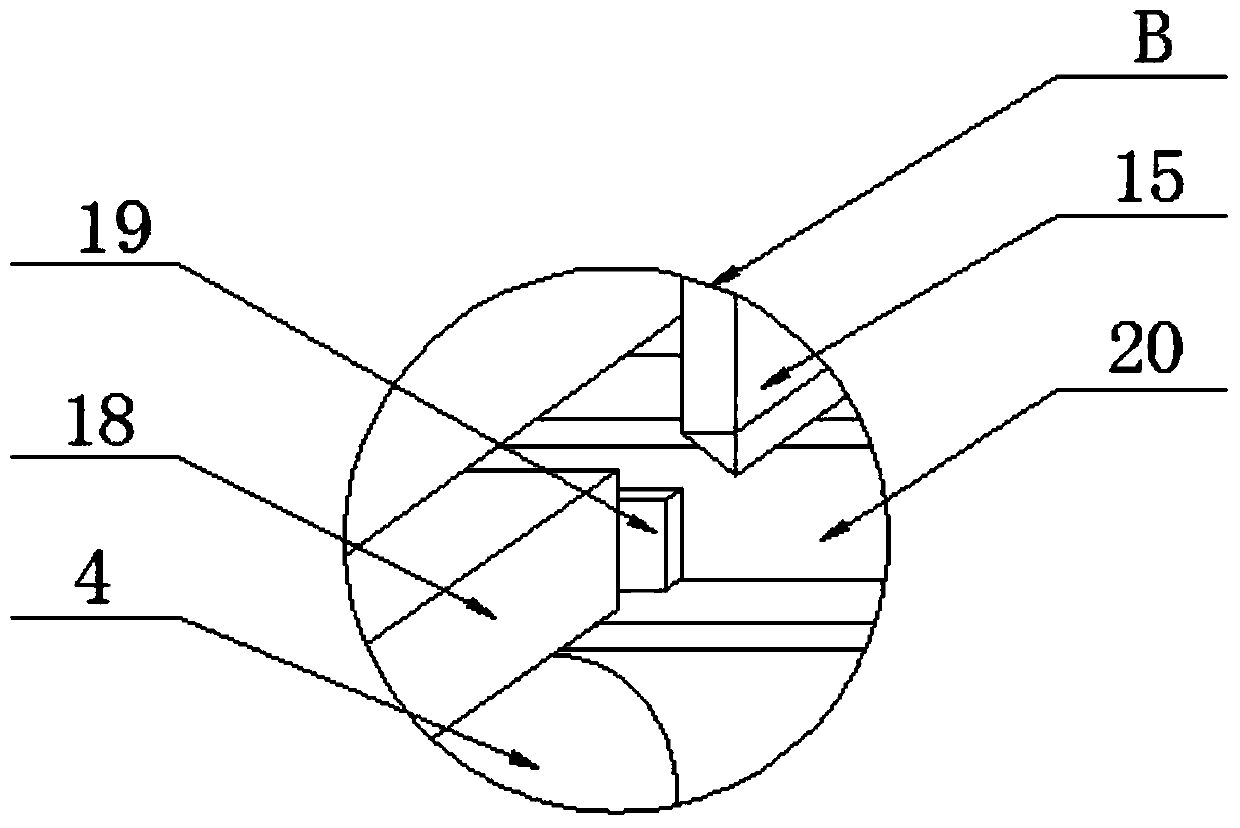

[0025] see Figure 1-7 , in an embodiment of the present invention, a high-precision cutting device for stainless steel coils for construction engineering, including a fixed bracket 1 and a connecting bracket 2, one side of the fixed bracket 1 is fixedly connected with the connecting bracket 2, and the upper surface of the fixed bracket 1 is fixed Connected with a support plate 4, the lower surface of the support plate 4 is fixedly equipped with a dust collection cover 3, and the upper surface side end of the support plate 4 is equipped with a first hydraulic cylinder 5, and the first hydraulic cylinder 5 includes a working panel 18, a slide block 19, The second push bar 21, connecting seat 22, reinforcing bolt 23 and placing platform 24, one side of work panel 18 is fixedly connected with slide block 19, and the upper surface of work panel 18 is fixedly connected with placing platform 24, and one side of placing platform 24 A connecting seat 22 is fixedly connected, and a rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com