CNC machine tools for woodworking

A CNC machine tool and wood technology, applied in the field of electrical machinery, can solve the problems of insufficient clamping, easy falling down, and affecting wood fixing, etc., and achieve the effects of convenient implementation, loosening prevention, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

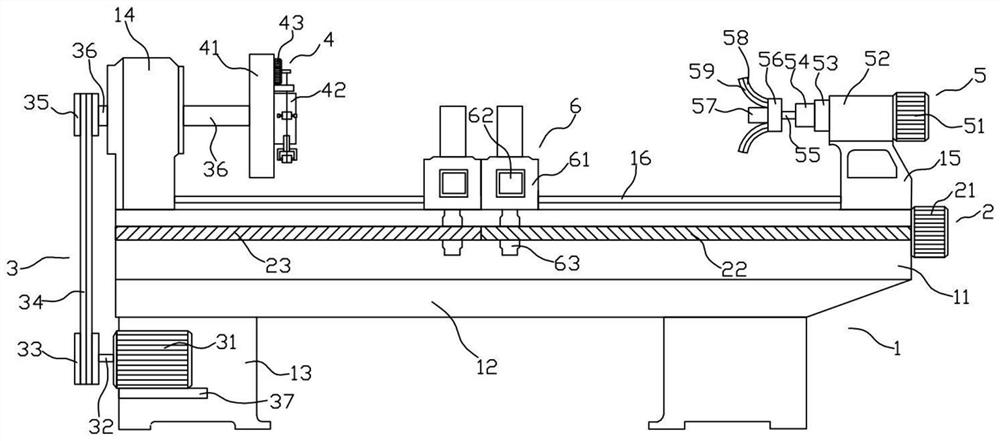

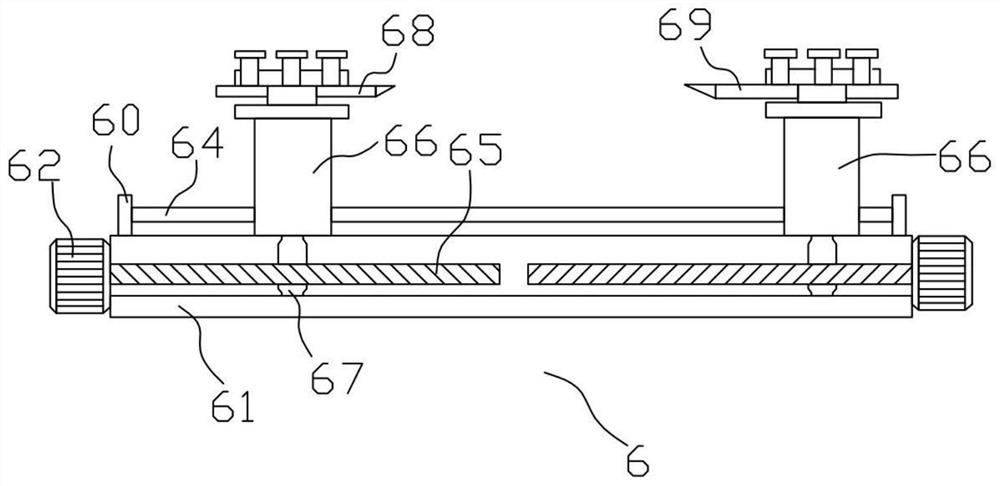

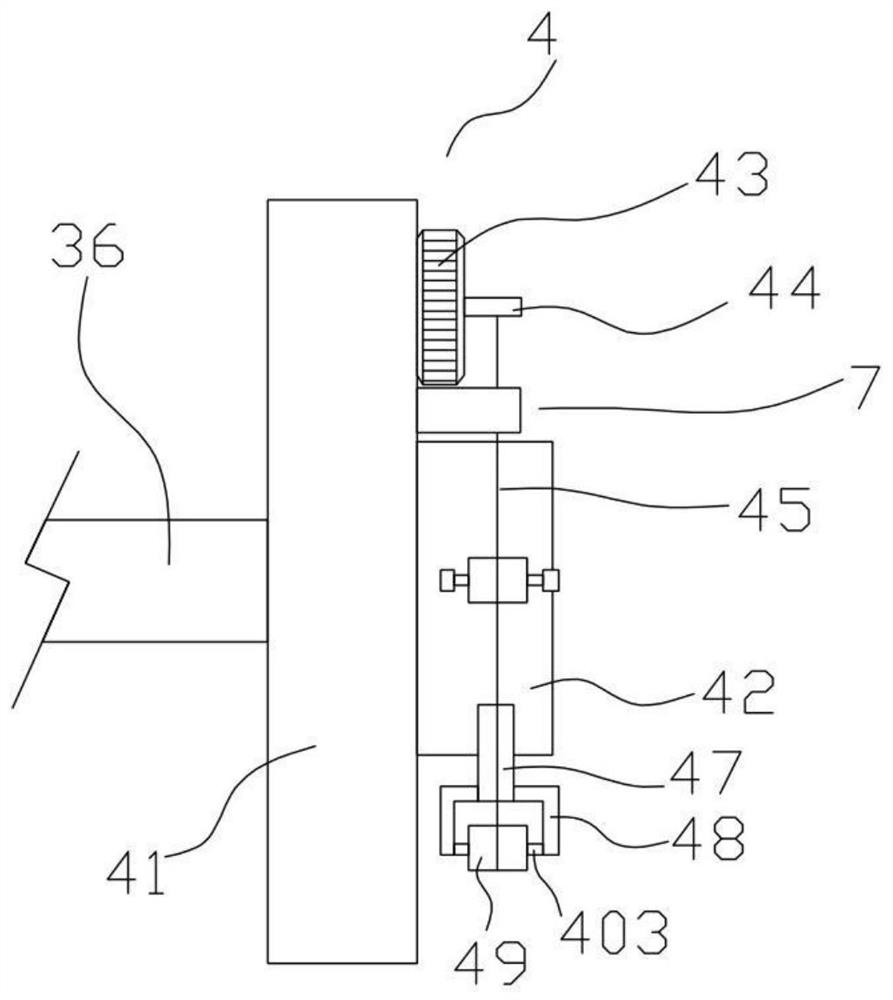

[0018] like Figure 1 to Figure 7 As shown, the numerical control machine tool for wood processing according to the present invention comprises a worktable structure 1, a drive structure 2 arranged on the worktable structure 1, a belt structure 3 provided on one side of the worktable structure 1, and a belt structure 3 provided on the belt structure 3. The clamping structure 4 , the abutting structure 5 arranged on the other side of the table structure 1 , the engraving structure 6 arranged between the abutting structure 5 and the clamping structure 4 , the limiting structure 7 arranged on the clamping structure 4 .

[0019] like figure 1 As shown, the workbench structure 1 includes a workbench 11, a support plate 12 disposed below the workbench 11, a plurality of support legs 13 disposed below the support plate 12, a first support column 14 disposed on the upper end side of the workbench 11, The second support column 15 is disposed on the other side of the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com