Beam bottom arching form supporting device

A technology of beam side formwork and supporting beams, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of inaccurate design or specification It is required to solve problems such as arching and the influence of the bearing capacity of large-span structural beams, so as to achieve the effect of simple production and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

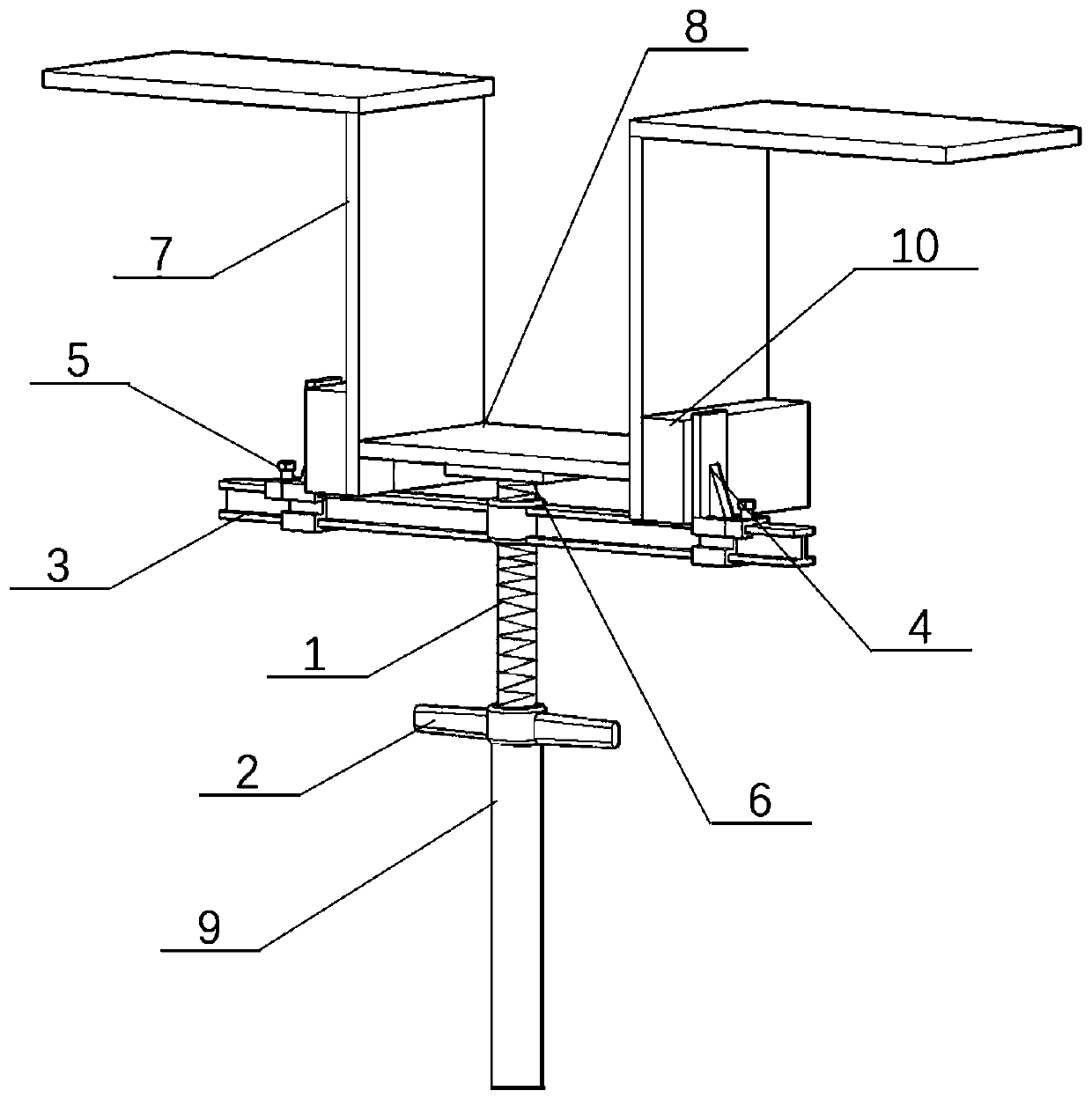

[0014] Such as figure 1 As shown, when the installation of the vertical rod 9 at the bottom of the beam is completed, the supporting device integrating the adjusting nut 2, the horizontal support rod 3, the fastener 4 of the beam side form, the positioning bolt 5 and the supporting plate 6 is placed on the vertical rod at the bottom of the beam. within 1. The height of the screw rod 1 is adjusted according to the floor height and the arching height at the bottom of the beam. The horizontal support bar 3 is adjusted to the distance between the supporting plate 6 according to the arching height of the beam bottom. The supporting plate 6 supports the bottom formwork 8 of the beam. Square 10 realizes reinforcement of beam side formwork 7.

[0015] Although the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com