Gas-liquid separating and liquid recycling device

A technology of liquid circulation and gas-liquid separation, applied in separation methods, components of pumping devices for elastic fluids, separation of dispersed particles, etc., can solve the problems that cannot meet the needs of liquid ring pumps, technical problems, and reduction of working fluid To achieve the effect of protecting gas tightness, improving retention capacity, and expanding adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

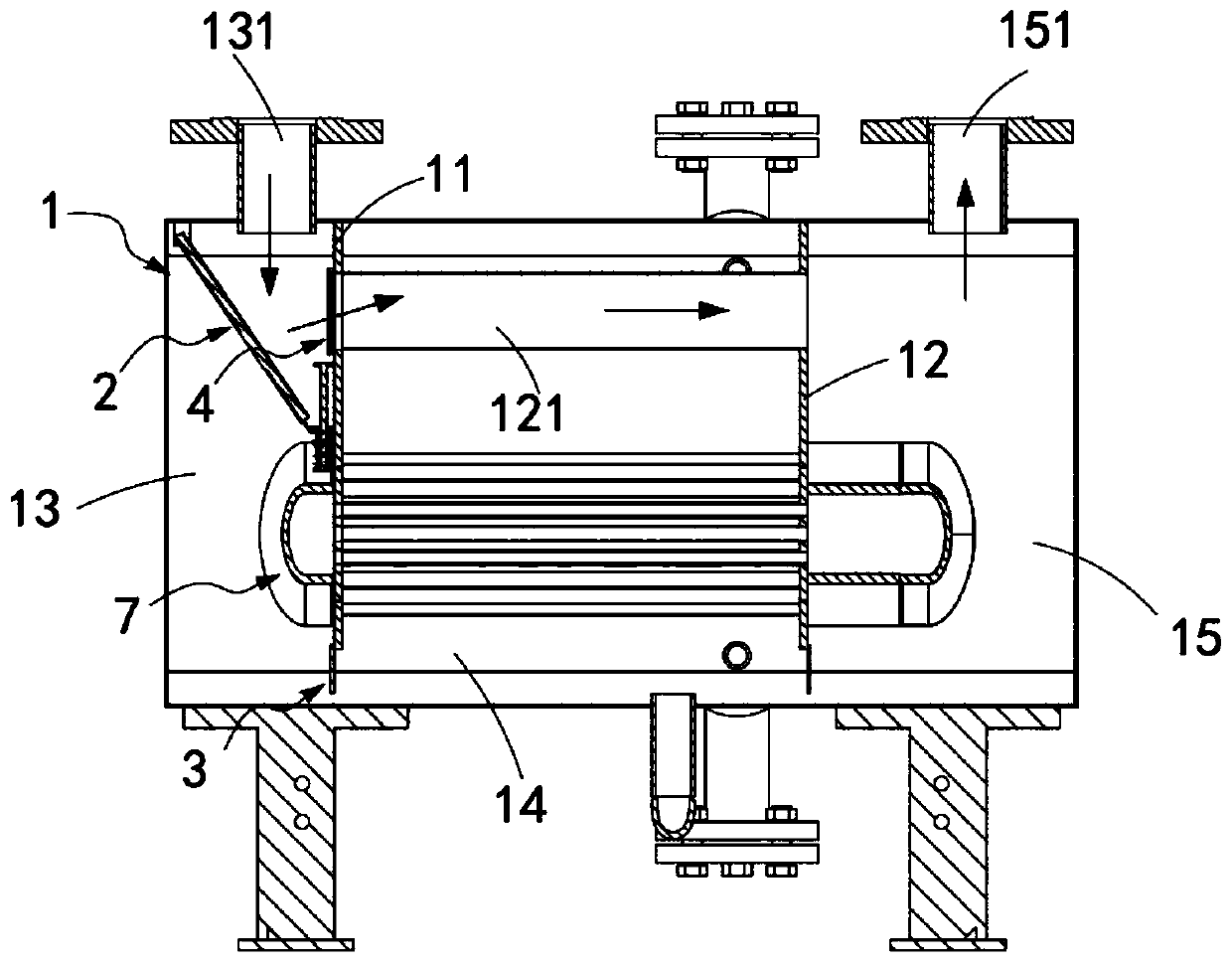

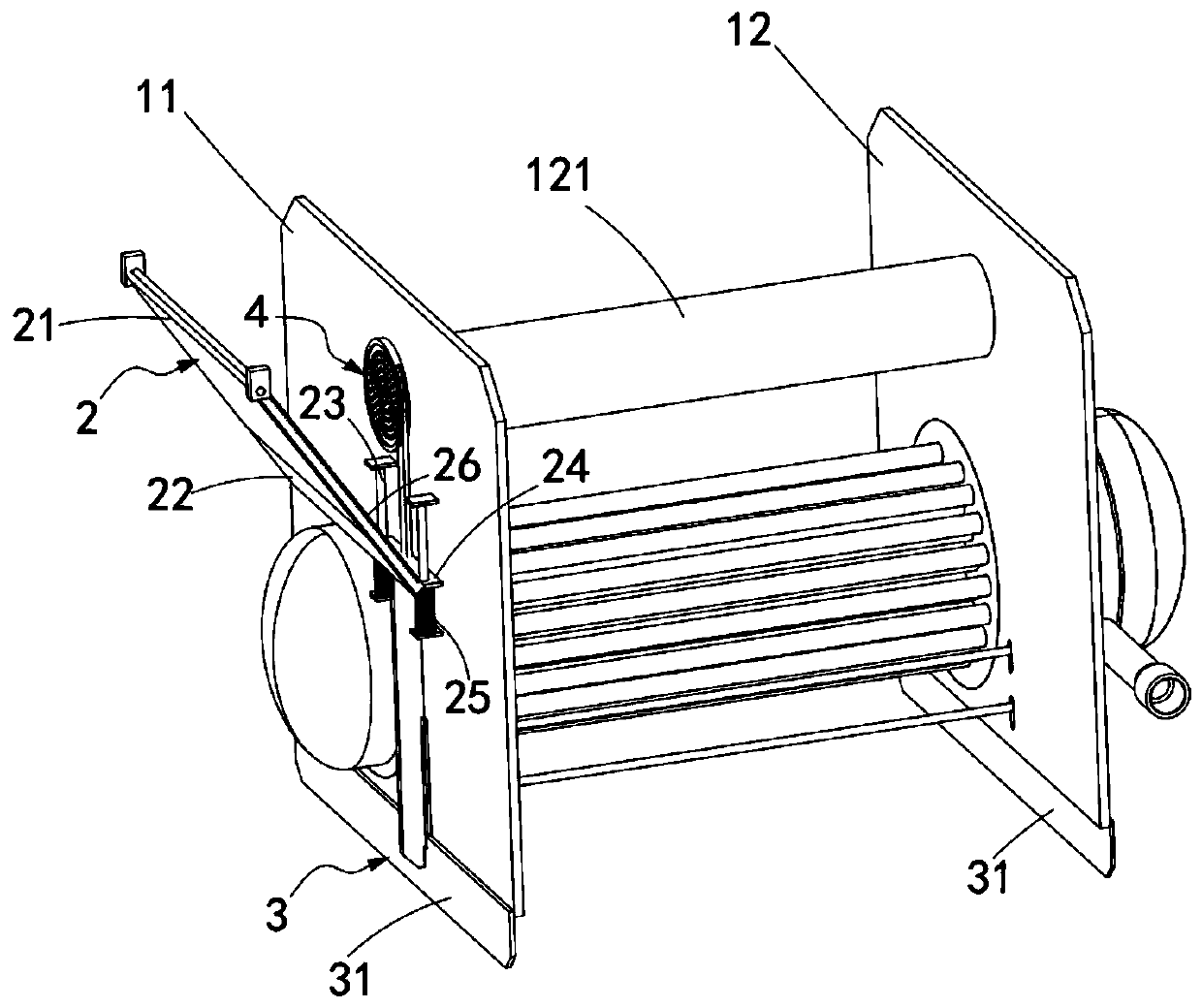

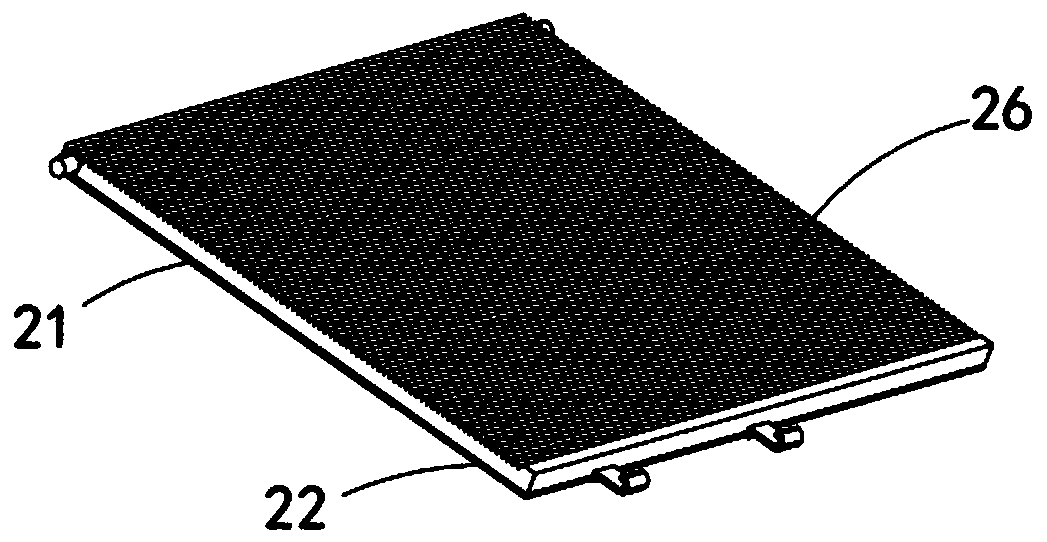

[0057] Such as Figure 1 to Figure 4 As shown, a gas-liquid separation liquid recycling device includes a square tank body 1, a first partition 11 and a second partition 12 are arranged in the square tank body 1, so that the square tank body 1 is sequentially arranged along the length direction Divided into a first compartment 13, a second compartment 14 and a third compartment 15, and the first compartment 13, the second compartment 14 and the third compartment 15 pass through the first partition 11 and the third compartment 15. The communication port 111 provided at the bottom of the second partition 12 communicates, and an exhaust pipe communicating with the first compartment 13 and the third compartment 15 is provided between the first partition 11 and the second partition 12 112, the top of the first compartment 13 is provided with a waste gas liquid inlet 131, the top of the third compartment 15 is provided with a waste gas discharge port 151 for discharging waste gas, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com