Hydraulic control system for straight-stroke gas-liquid linkage actuating mechanism

A hydraulic control system and gas-hydraulic linkage technology, applied in the field of hydraulic control, can solve the problems of not independent energy storage, low safety factor, leakage, etc., and achieve the effect of low manufacturing cost, high safety, and few high-pressure parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

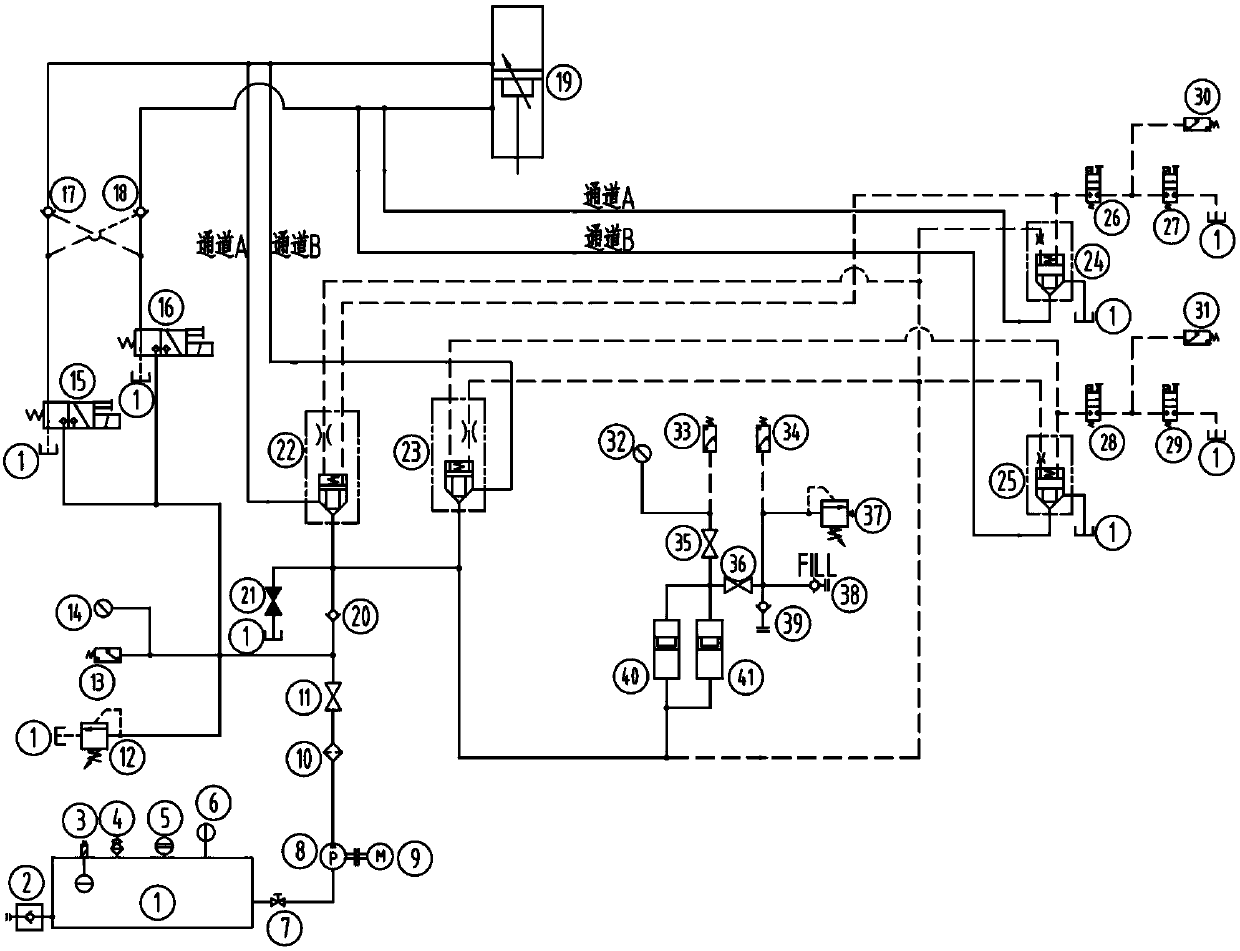

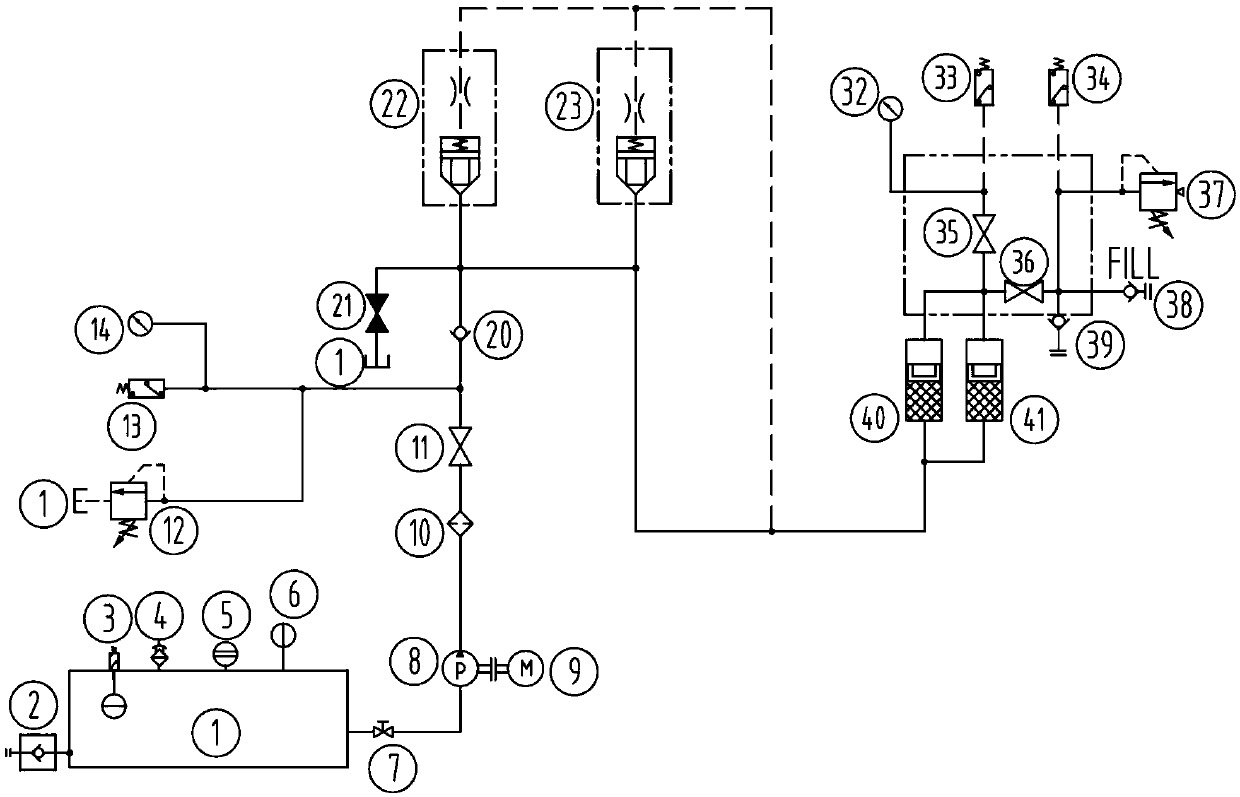

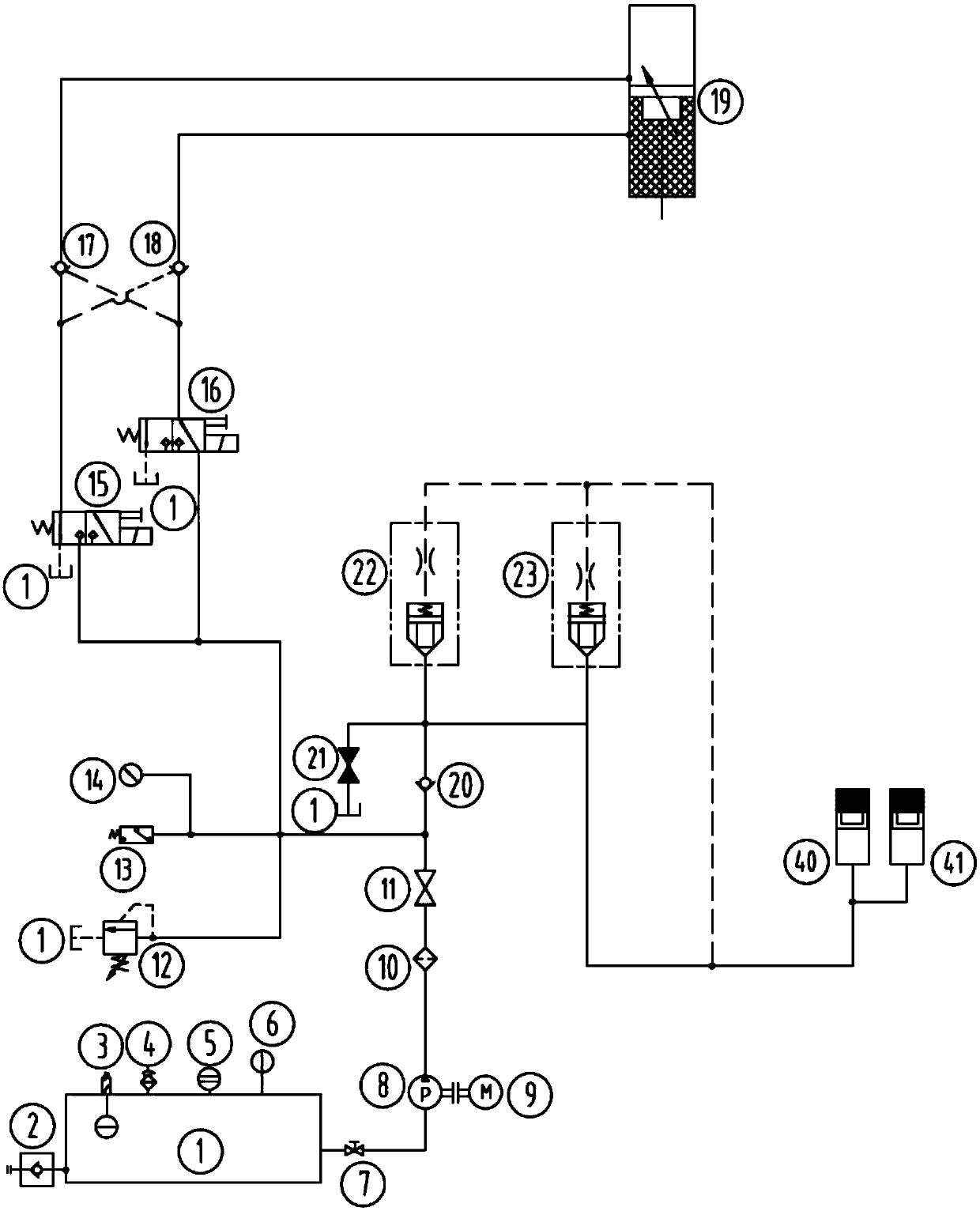

[0028] Such as figure 1 As shown, the hydraulic system includes a fuel tank 1, four two-way cartridge valves (the first two-way cartridge valve 22, the second two-way cartridge valve 23, the third two-way cartridge valve 24, the fourth two-way cartridge valve Valve 25), two first accumulators (first accumulator 40, second accumulator 41), and associated connected pipelines.

[0029] In order to realize the functions of pressure accumulation, slow switching or fast closing, relevant valves, switches and instruments are installed on the corresponding pipelines.

[0030] Such as figure 2 As shown, the refueling port 2, liquid level switch 3, breather valve 4, liquid level gauge 5, and thermometer 6 are all installed on the fuel tank 1, the refueling port 2 is used to add hydraulic oil to the fuel tank 1, and the liquid level switch 3 is used for low li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com