Vibration table test loading device with load decoupling function and using method

A technology of shaking table test and loading device, which is applied in vibration test, foundation structure test, measuring device, etc. It can solve problems such as inability to decouple, slow progress in research on physical model tests of seismic load effects on pile foundations, etc., and improve execution efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

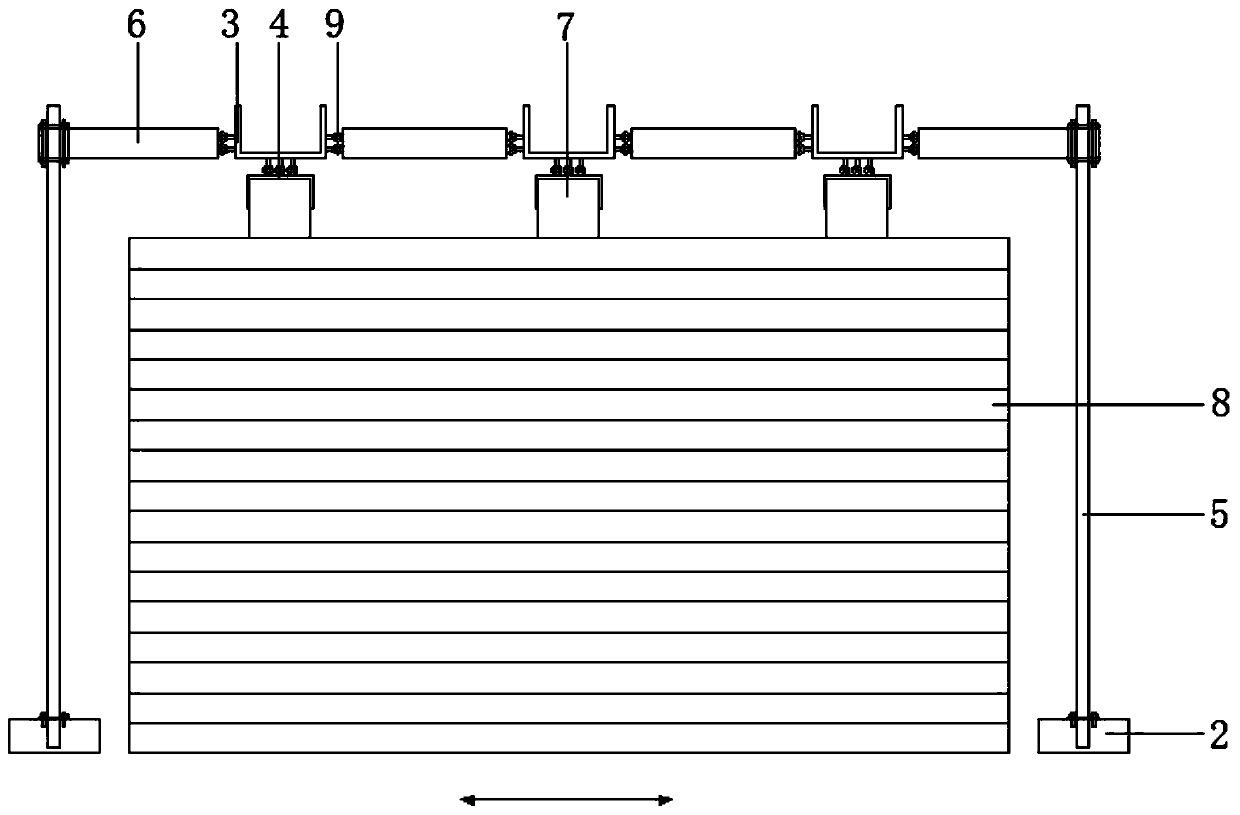

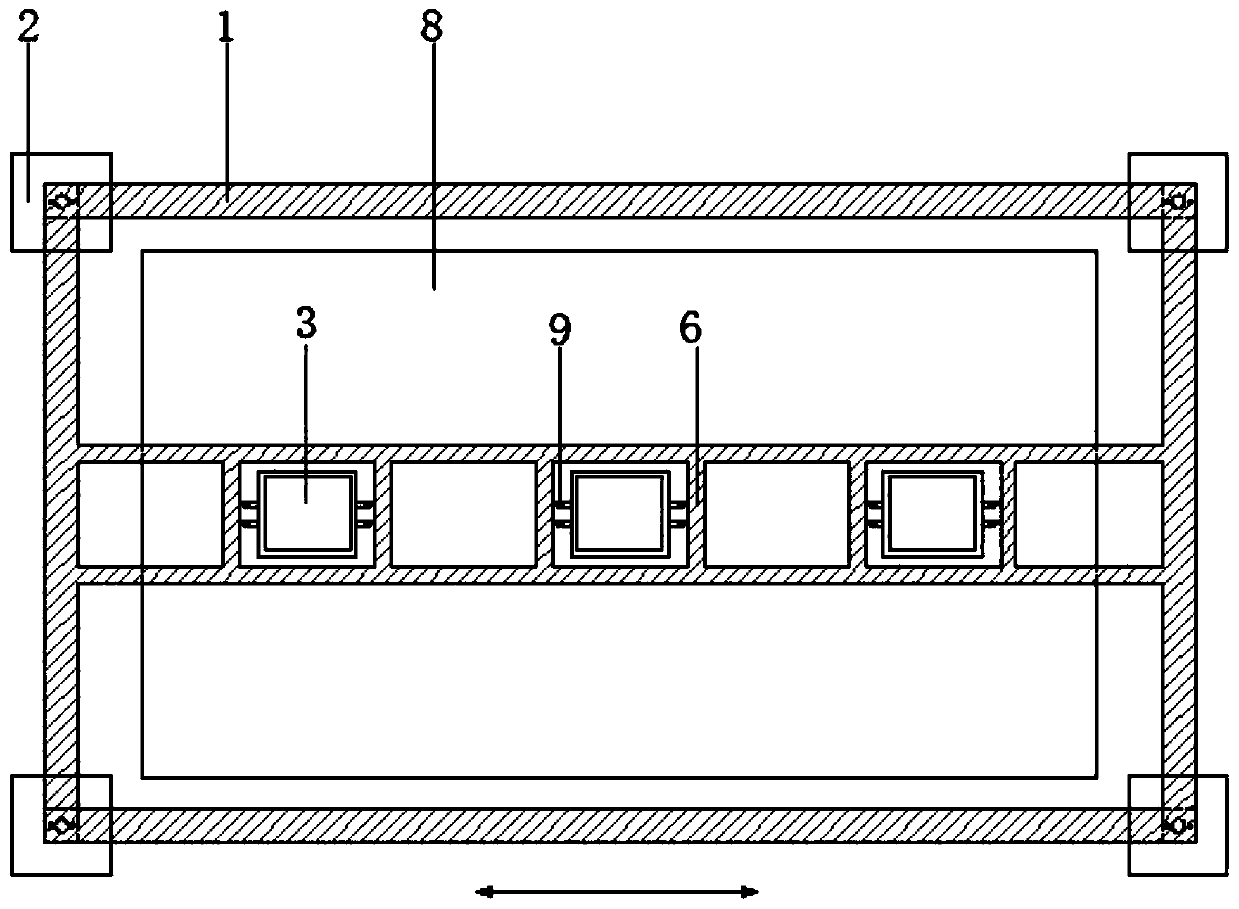

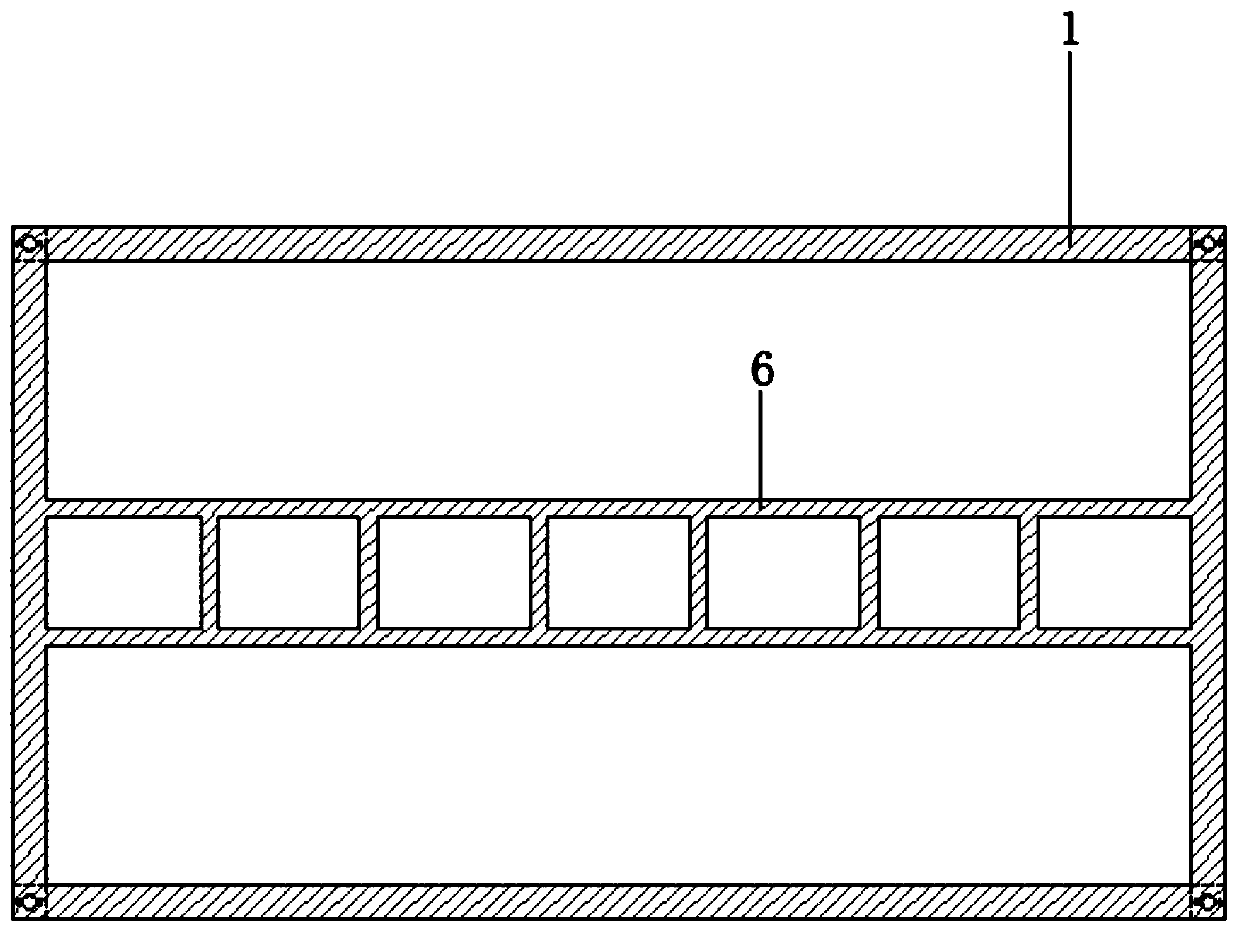

[0024] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, the present invention discloses a shaking table test loading device with a load decoupling function, which includes a lateral limit frame 1, a lateral limit frame 6, four counterweight column feet 2, four hollow steel pipes 5, and a plurality of guide cars 3 and a plurality of pile head baffles 4; the four counterweight column feet 2 are arranged on the outside of the vibration table 8 along the circumference of the vibration table 8, and the lateral limit frame 1 is horizontally arranged on the upper ends of a plurality of model piles 7 And through four hollow steel pipes 5 and four counterweight column feet 2 one-to-one detachable fixed connection (side limit frame 1 is a rectangular frame, the four corners of the rectangular frame and the middle part of each counterweight column foot 2 are set There are mounting holes, the lower end of each corner of the rectangular frame and the upper end of each co...

specific Embodiment approach 2

[0025] Specific embodiment 2: This embodiment is a further description of specific embodiment 1. The lateral limit frame 1, the lateral limit frame 6, the four counterweight column feet 2, the four hollow steel pipes 5, and a plurality of guide cars 3 And a plurality of pile head baffles 4 are all prefabricated by steel.

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of the second embodiment, and the four counterweight column feet 2 are arranged in a rectangular array.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap