Manufacturing process of anti-sudden short circuit amorphous alloy transformer coil

A transformer coil and manufacturing process technology, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, circuit, etc., can solve the problem of insufficient sudden short-circuit resistance of amorphous alloy transformers, and achieve enhanced short-circuit resistance and uniform force , the effect of line arrangement rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

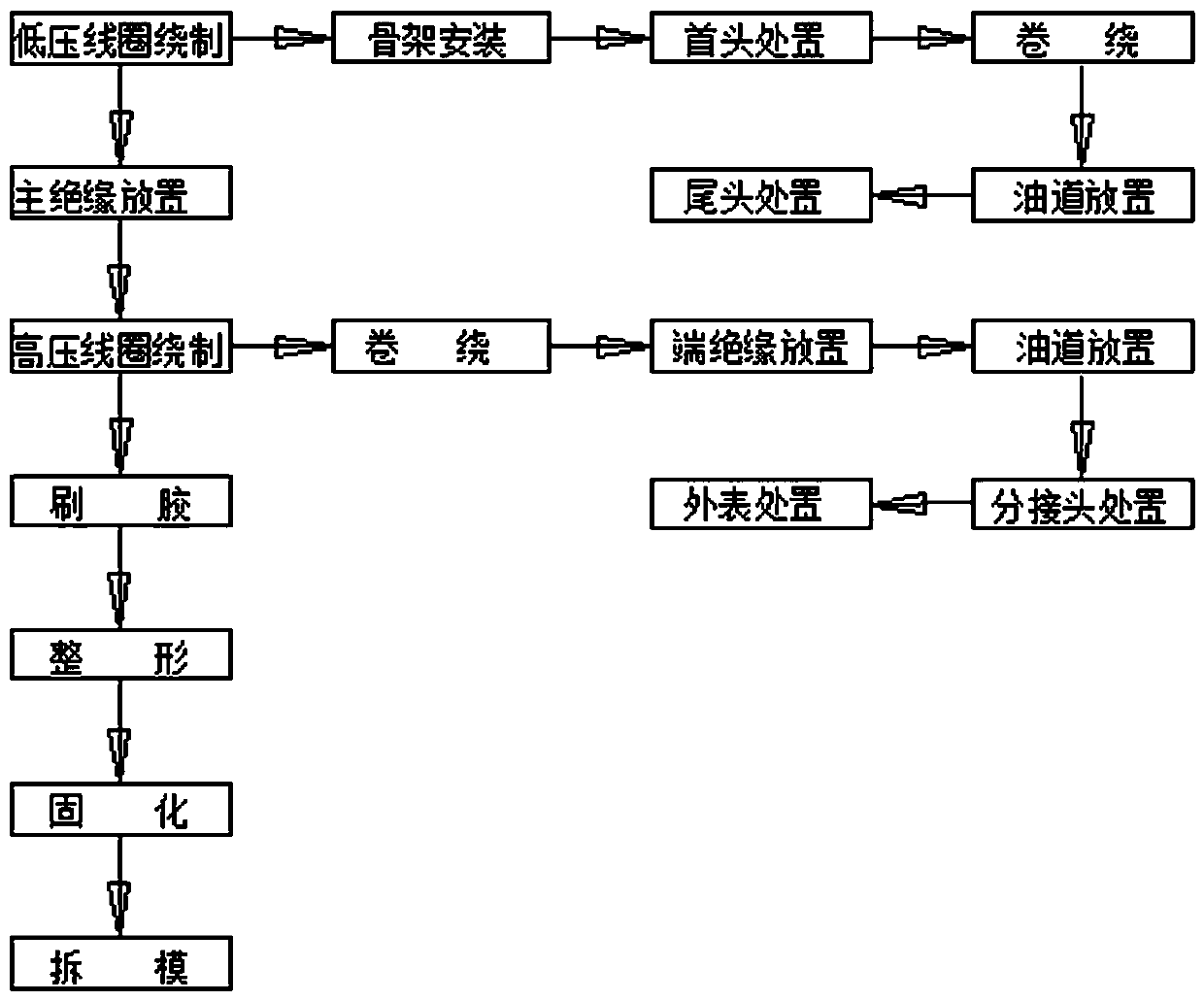

[0035] Such as figure 1 As shown, the manufacturing process of the anti-sudden short-circuit amorphous alloy transformer coil includes the following steps:

[0036] Step 1. Low-voltage coil winding:

[0037] a. Skeleton installation, put a 3mm thick skeleton into the winding mold, align it with the foil and interlayer insulation and fix it, and wrap a layer of full adhesive paper on the skeleton. The skeleton is a hard epoxy glass cloth tube. The interlayer insulation is fully glued paper. Full-adhesive paper can meet the insulation strength between layers of low-voltage coils and ensure the compactness and resistance to external forces of low-voltage coils. Because of its super-strong adhesive force after heating, it can ensure the integrity of the coil structure after heat curing.

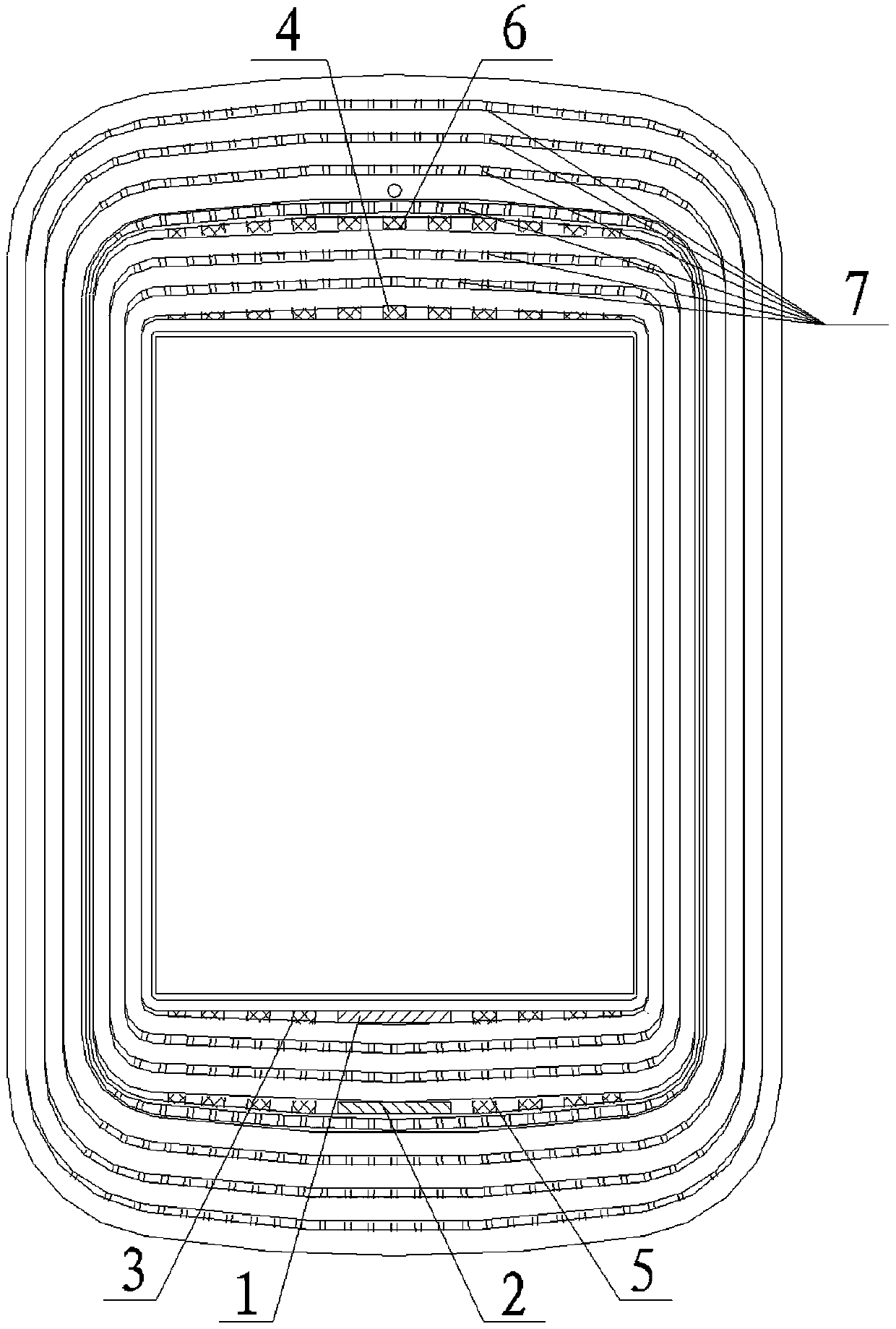

[0038] b. For the treatment of the head, the first copper bar is cushioned with a stepped oil passage to form an excessive arc without leaving a cavity, forming a stepped oil passage 3 at the ...

Embodiment 2

[0054] Such as figure 1 As shown, the manufacturing process of the anti-sudden short-circuit amorphous alloy transformer coil includes the following steps:

[0055] Step 1. Low-voltage coil winding:

[0056] a. Skeleton installation, put the 8mm thick skeleton into the winding mold, align it with the foil and interlayer insulation and fix it, and wrap a layer of full adhesive paper on the skeleton. The skeleton is a hard epoxy glass cloth tube. The interlayer insulation is fully glued paper. Full-adhesive paper can meet the insulation strength between layers of low-voltage coils and ensure the compactness and resistance to external forces of low-voltage coils. Because of its super-strong adhesive force after heating, it can ensure the integrity of the coil structure after heat curing.

[0057] b. For head treatment, the copper bar at the head is padded with stepped oil passages to form an excessive arc without leaving a cavity. The head corresponds to the opposite side of ...

Embodiment 3

[0072] Such as figure 1 As shown, the manufacturing process of the anti-sudden short-circuit amorphous alloy transformer coil includes the following steps:

[0073] Step 1. Low-voltage coil winding:

[0074] a. Skeleton installation, put a 6mm thick skeleton into the winding mold, align it with the foil and interlayer insulation and fix it, and wrap a layer of full adhesive paper on the skeleton. The skeleton is a hard epoxy glass cloth tube. The interlayer insulation is fully glued paper. Full-adhesive paper can meet the insulation strength between layers of low-voltage coils and ensure the compactness and resistance to external forces of low-voltage coils. Because of its super-strong adhesive force after heating, it can ensure the integrity of the coil structure after heat curing.

[0075] b. For head treatment, the copper bar at the head is padded with stepped oil passages to form an excessive arc without leaving a cavity. The head corresponds to the opposite side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com