High-power hub motor power wheel

An in-wheel motor, high-power technology, used in power units, electric components, electromechanical devices, etc., can solve the problem of only installing low-power motors, and it is impossible to meet the requirements of high-power motors, so as to reduce volume and production. Manufacturing cost, effect of increasing gradeability and driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

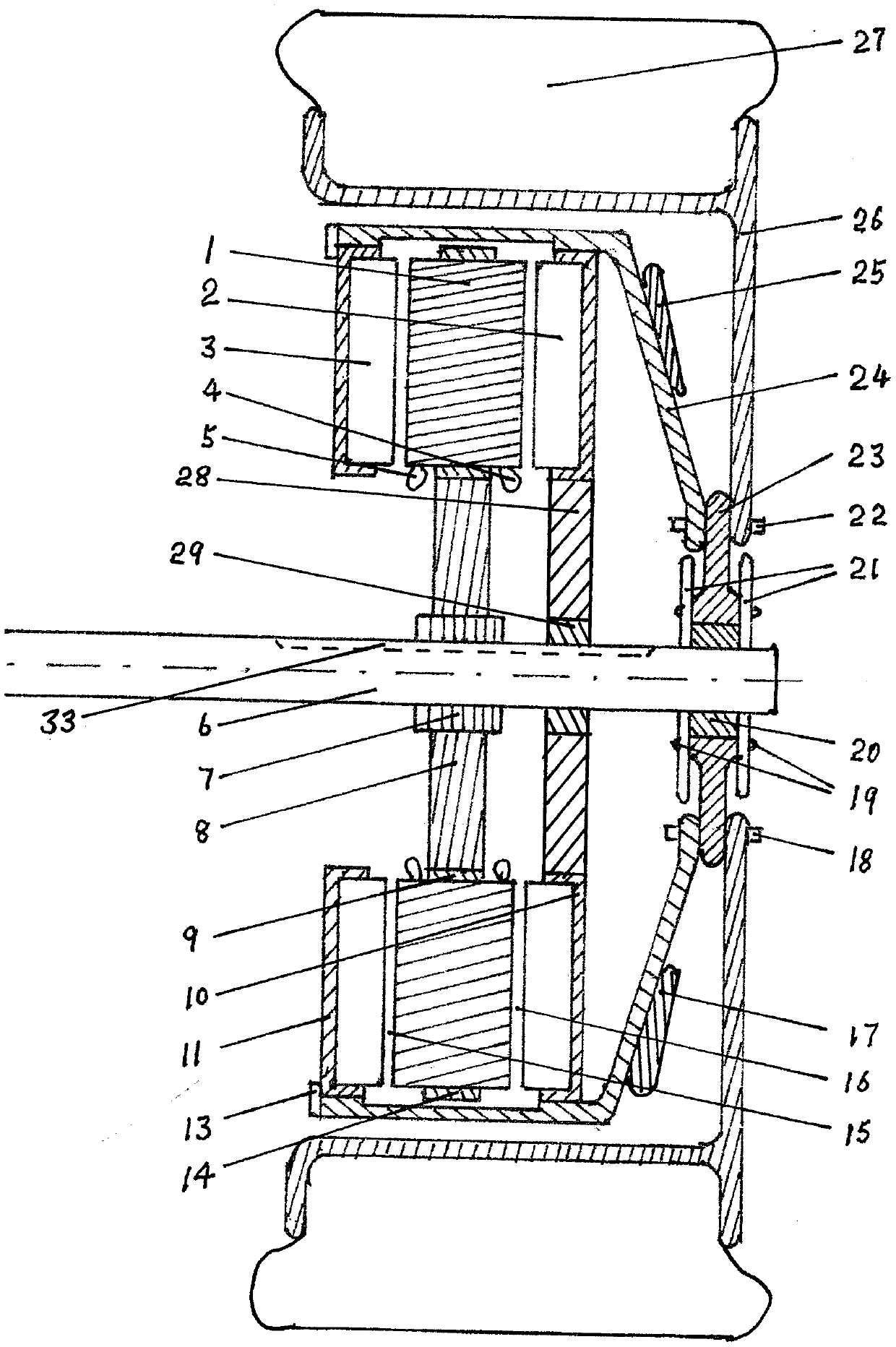

[0025] Below again in conjunction with accompanying drawing, the specific embodiment of the application of the present invention is described in further detail:

[0026] As shown in the accompanying drawings, it is an embodiment of the application of the present invention.

[0027] People can make a toroidal stator 1 according to the usual manufacturing method of a disc motor, and make the two sides of the toroidal stator 1 have two annular planes. At the same time, use the inner circle yoke 9 and the outer circle yoke 14 of the stator 1 to forcefully clamp and fix the annular body stator 1 from the inner circle direction of the stator 1 ring body outward and from the outer circle direction inward.

[0028] On the two annular planes on both sides of the annular body stator 1, slots for installing the coil winding 4 and the coil winding 5 are opened respectively, and then the insulating material is put in according to the rules and procedures, and the coil is embedded, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com