Printing process for cosmetic packaging bottle cap

A technology for packaging bottle caps and cosmetics. It is applied in printing, printing machines, rotary printing machines, etc. It can solve the problems that affect the formation of patterns and characters, and the slow speed of solidification and drying, so as to achieve faster curing speed, long service life and good adhesion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

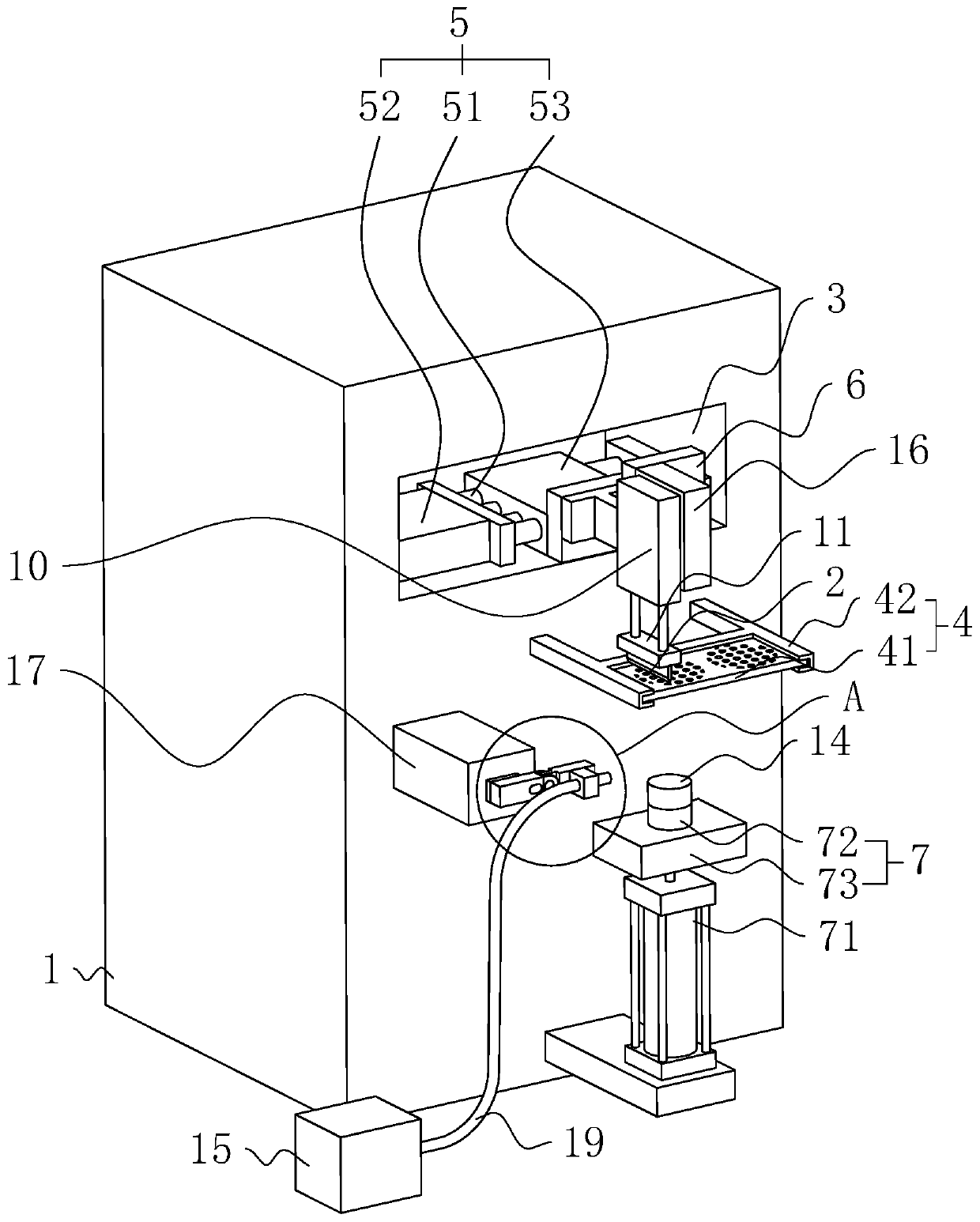

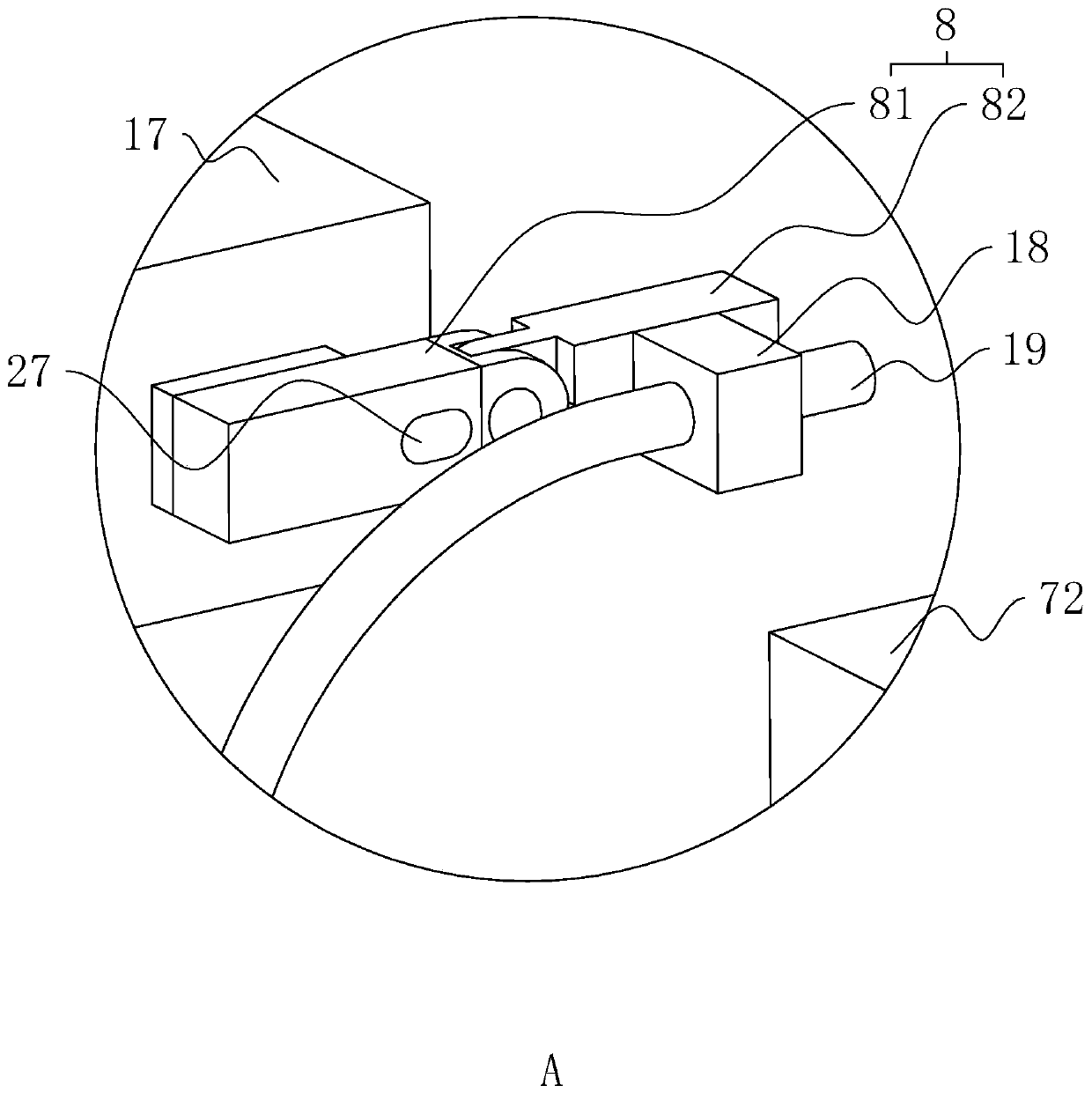

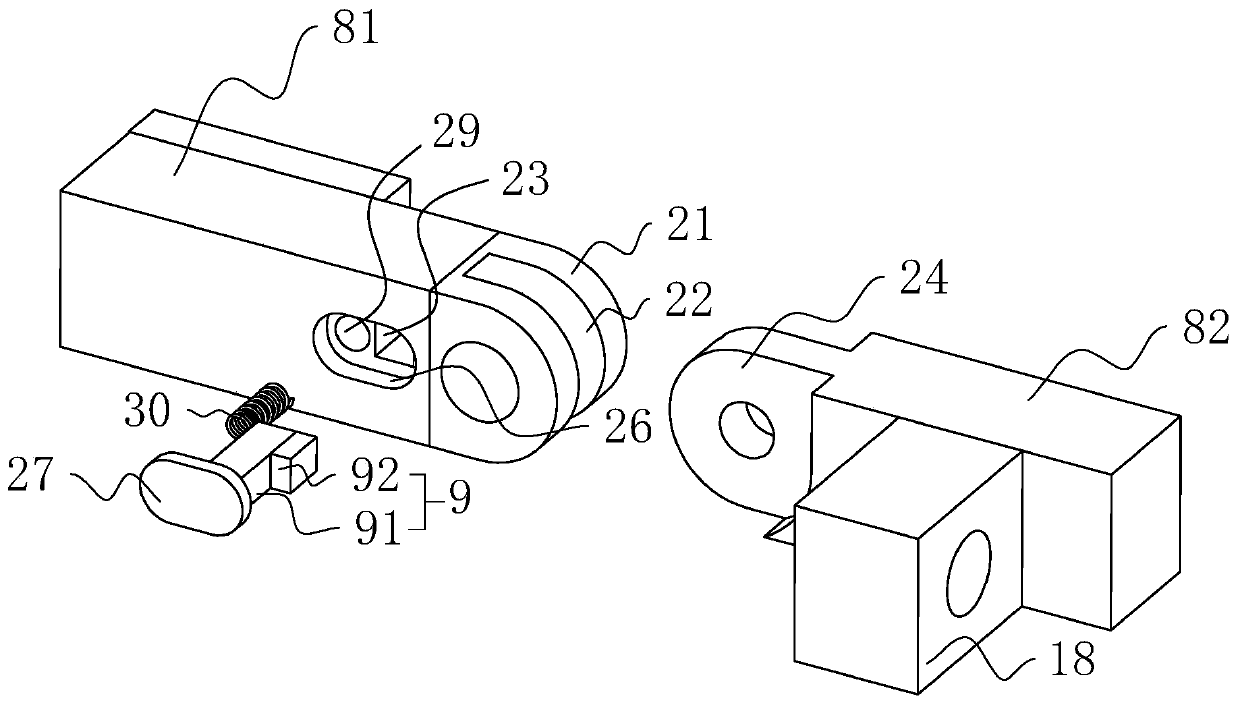

[0046] refer to figure 1 , a printing process for cosmetic packaging bottle caps, all steps are carried out on a flat screen screen printing machine. A flat screen screen printing machine includes a machine body 1. A printing assembly 4 is arranged on the side wall of the machine body 1 , and the printing assembly 4 includes a fixing bracket 41 and a screen printing screen 42 . The fixed bracket 41 is fixedly arranged on the side wall of the machine body 1 , the screen printing screen 42 is arranged on the fixing bracket 41 , and a plurality of discharge holes are opened on the screen printing screen 42 . The shape of the screen printing screen 42 is rectangular, and the length direction of the screen printing screen 42 is parallel to the side wall of the body 1 on which the fixing bracket 41 is installed. The upper surface of the screen printing screen 42 is slidably provided with a screen printing scraper 2 along the length direction. The screen printing scraper 2 is driv...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 lies in: S4: post-processing the bottle cap 14 after the treatment in S3. The post-processing process is that the staff use a brush to soak the protective agent. The raw materials of the protective agent include 40 parts of silica sol, 22 parts of toluenesulfonamide-formaldehyde resin, 2.5 parts of m-xylylenediamine and ethanolamine acetate in parts by weight. 24 servings. The staff uses a brush soaked in protective agent to apply protective agent to the graphic layer after S3 treatment. After the protective agent is evenly applied, the staff starts the blower 15 again to send hot air towards the upper surface of the bottle cap 14, so that the upper surface of the bottle cap 14 is kept at 70°C, and blows continuously for 4 minutes, and then the staff removes the bottle cap 14 from the plug post 72 and unplug it.

[0063] The difference between Examples 3-6 and Example 2 is that the raw materials of the protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com