A method for preparing holmium oxide nanomaterials with different shapes

A technology for nanomaterials and holmium oxide, which is applied in the field of preparing holmium oxide nanomaterials, can solve the problems of complex synthesis steps, high difficulty, inability to synthesize nanotube morphology and three-dimensional structure holmium oxide nanomaterials, etc., and achieves excellent performance and stable structure. , the effect of excellent moisture sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Specific embodiment one: a kind of method for preparing holmium oxide nanomaterials with different shapes described in this embodiment, it is carried out according to the following steps:

[0039] 1. Dissolve holmium acetylacetonate and urea in the solvent, and magnetically stir for 0.5h to 2h to obtain a uniformly stirred solution;

[0040] The molar ratio of described holmium acetylacetonate and urea is 1:(0.5~6); The volume ratio of the total moles of described holmium acetylacetonate and urea to solvent is 1mmol:(4~13)mL; The described Solvent is made up of ethylene glycol, polyethylene glycol 400 and deionized water; The volume ratio of described ethylene glycol and polyethylene glycol 400 is 1:(0.9~1.1); Described ethylene glycol and deionized The volume ratio of water is 1:(0.15~0.7);

[0041] 2. Place the uniformly stirred solution in a polytetrafluoroethylene-lined stainless steel reaction kettle and seal it, and react for 8h to 16h at a temperature of 140°C t...

specific Embodiment approach 2

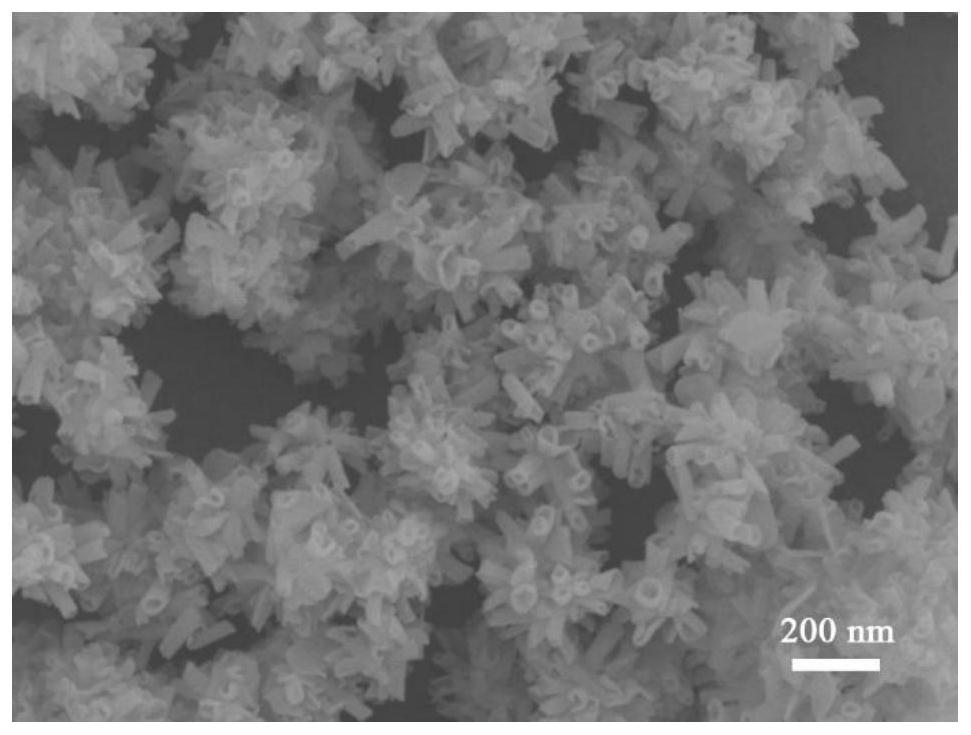

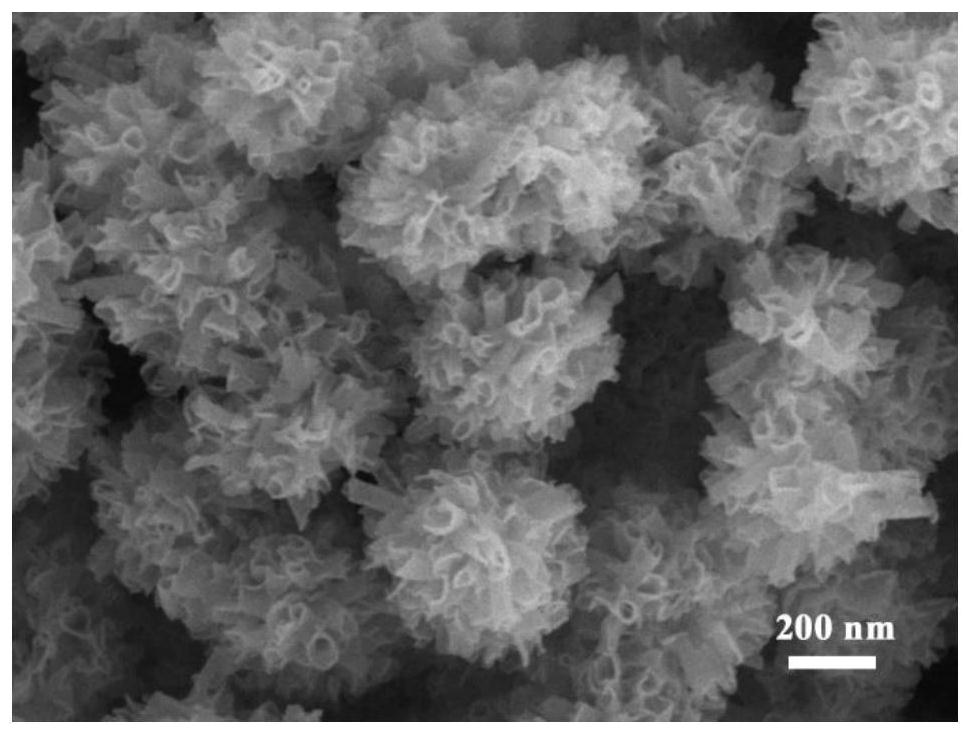

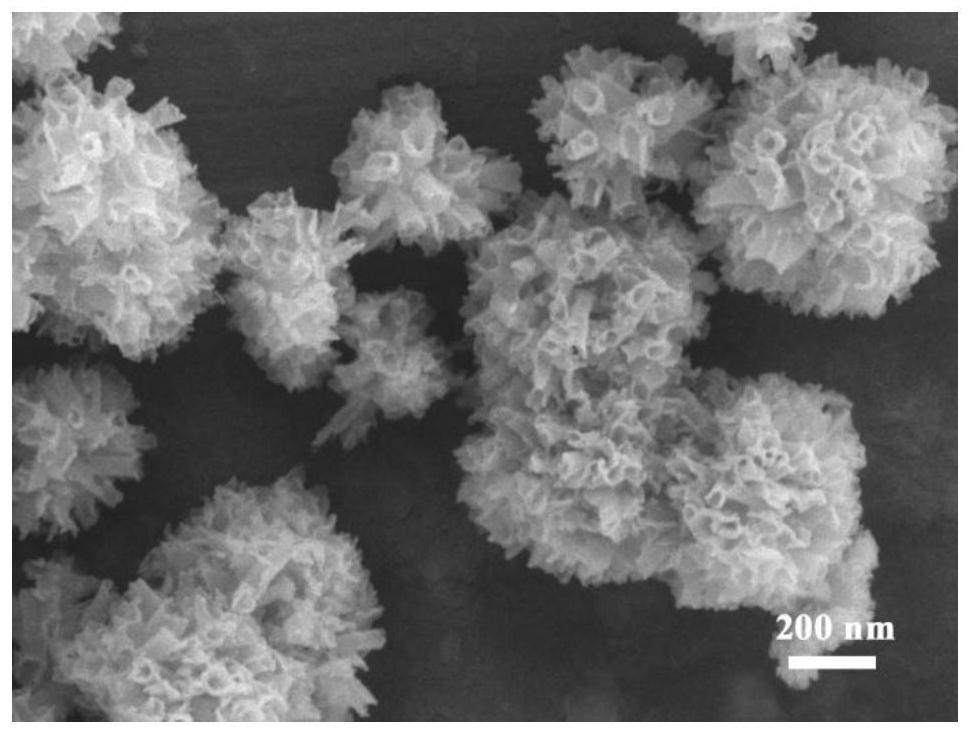

[0047] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the holmium oxide nanomaterials prepared in step 2 have nanotubes, spheres formed by self-assembly of nanotubes, nanosheets, or spheres formed by self-assembly of nanosheets. . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, the light yellow precipitate is washed and then dried according to the following steps: wash several times with deionized water and ethanol respectively, and then Under the condition that the temperature is 70°C-100°C, vacuum dry for 5h-12h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com