Roller-coating color UV coating for children furniture

A furniture and children's technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion, high hardness, and restrictions on the use of children's furniture, and achieve good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

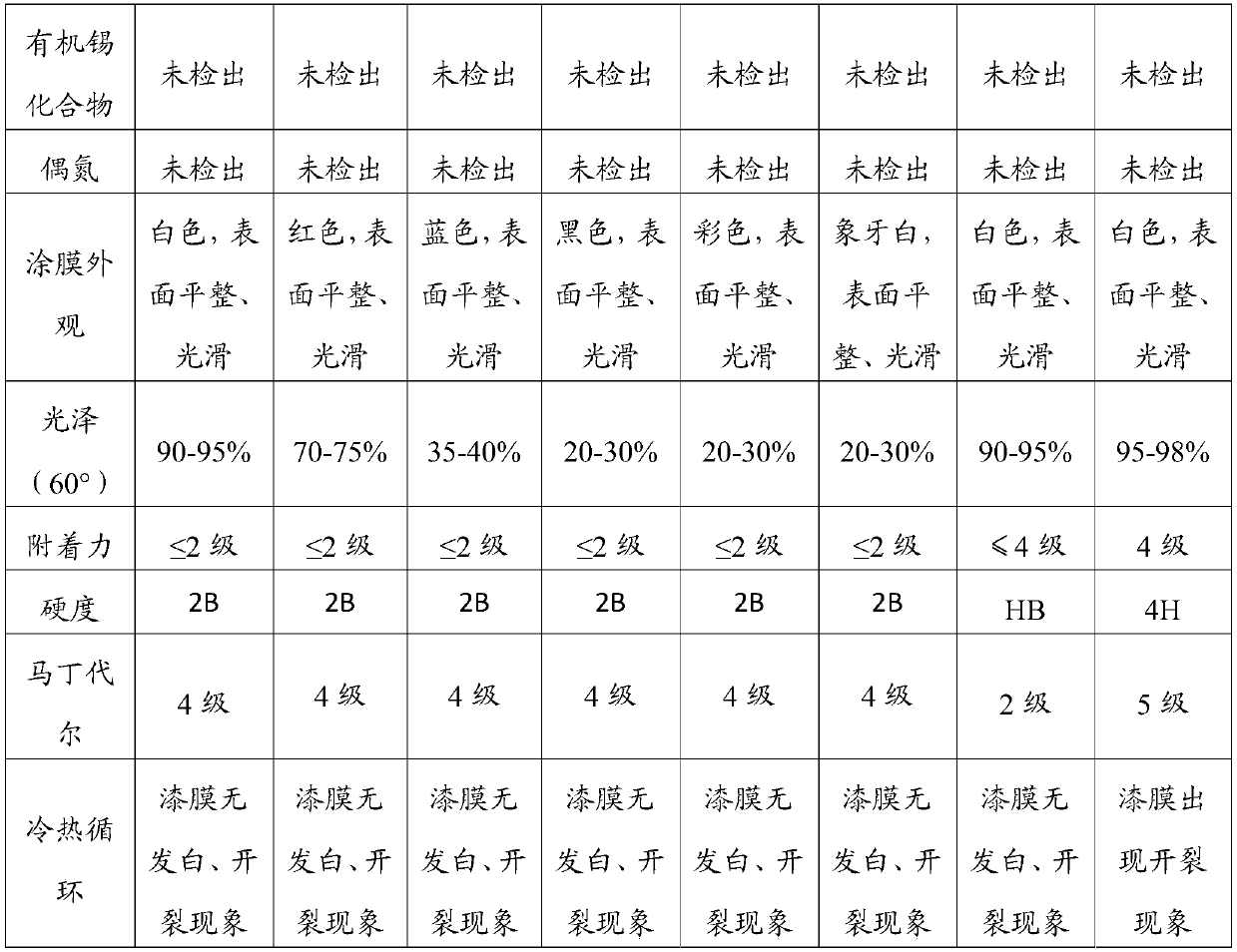

Embodiment 1

[0028] Roller colored UV paint for children's furniture, consisting of component A and component B in a weight ratio of 0.03-0.25:1;

[0029] The A component is 25kgCCA color paste titanium white paste UV810;

[0030] The B component consists of the following components:

[0031] Aliphatic polyurethane acrylic resin: 10kg allnex resin EB264, 20kg Changxing chemical 6145-100 and 15kg Baojun chemical 2602B

[0032] Functional monomer: 10kg Eternal Chemical EM222-TF, 10.45kg Eternal Chemical EM223-TF, 5kg Eternal Chemical EM231-TF and 10kg Eternal Chemical EM2380-TF;

[0033] Defoamer: 0.2kg Evonik Specialty Chemicals TEGO920;

[0034] Leveling agent: 0.1kg Evonik Specialty Chemicals TEGO450;

[0035] Filling: 15kg Guangxi Guiguang KB-10-2;

[0036] Photoinitiator: 1kg JRCure 1103, 2kg JRCure 1104 and 1kg JRCure 1109;

[0037] Dispersant: 0.2kg BYK-111;

[0038] Anti-settling agent: 0.05kg Evonik Specialty Chemicals A-200.

Embodiment 2

[0040] Roller colored UV coatings for children's furniture, consisting of components A and B in a weight ratio of 0.15:1;

[0041] The A component is 15kg CCA color paste UV832;

[0042] The B component consists of the following components:

[0043] Aliphatic polyurethane acrylic resin: 10kg allnex resin EB264, 15kg Changxing chemical 6145-100 and 15kg Baojun chemical 2602B

[0044] Functional monomer: 18.4kg Eternal Chemical EM222-TF, 10kg Eternal Chemical EM223-TF and 10kg Eternal Chemical EM2380-TF;

[0045] Defoamer: 0.2kg Evonik Specialty Chemicals TEGO920;

[0046] Leveling agent: 0.1kg BYK310 and 0.1kg Evonik Specialty Chemicals TEGO450;

[0047] Matting agent: 5kg American Grace RAD2105;

[0048] Packing: 5kg Guangxi Guiguang KB-10-2 and 5kg Guangxi Guiguang TY05-D;

[0049] Photoinitiator: 2kg JRCure 1103, 2kg JRCure 1104 and 1.5kg JRCure 1109;

[0050] Dispersant: 0.2kg BYK-111 and 0.2kg BYK-2009

[0051] Anti-settling agent: 0.3kg Evonik Specialty Chemicals A-2...

Embodiment 3

[0053] Roller colored UV coatings for children's furniture, consisting of components A and B in a weight ratio of 0.1:1;

[0054] The A component is 10kgCCA color paste UV841;

[0055] The B component consists of the following components:

[0056] Aliphatic polyurethane acrylic resin: 18kg Baojun Chemical 2602B and 20kg Changxing Chemical 6145-100;

[0057] Functional monomer: 20kg Eternal Chemical EM222-TF, 10kg Eternal Chemical EM223-TF and 10kg Eternal Chemical EM2380-TF;

[0058] Defoamer: 0.2kg Evonik Specialty Chemicals TEGO920;

[0059] Leveling agent: 0.1kg BYK310 and 0.1kg Evonik Specialty Chemicals TEGO450;

[0060] Matting agent: 10kg American Grace RAD2105;

[0061] Packing: 5kg Guangxi Guiguang TY05-D;

[0062] Photoinitiator: 2kg JRCure 1103, 2kg JRCure 1104 and 1.5kg JRCure 1109;

[0063] Dispersant: 0.2kg BYK-111 and 0.5kg BYK-2009;

[0064] Anti-settling agent: 0.4kg Evonik Specialty Chemicals A-200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com