Modified biochar-based soil conditioner for repairing Cd pollution, and preparation method and application thereof

A soil conditioner and biochar technology, which is used in the restoration of polluted soil, soil conditioning materials, applications, etc., can solve the problems of pollution and lack of repair materials, and achieve the effects of promoting crop growth, increasing pH value, and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

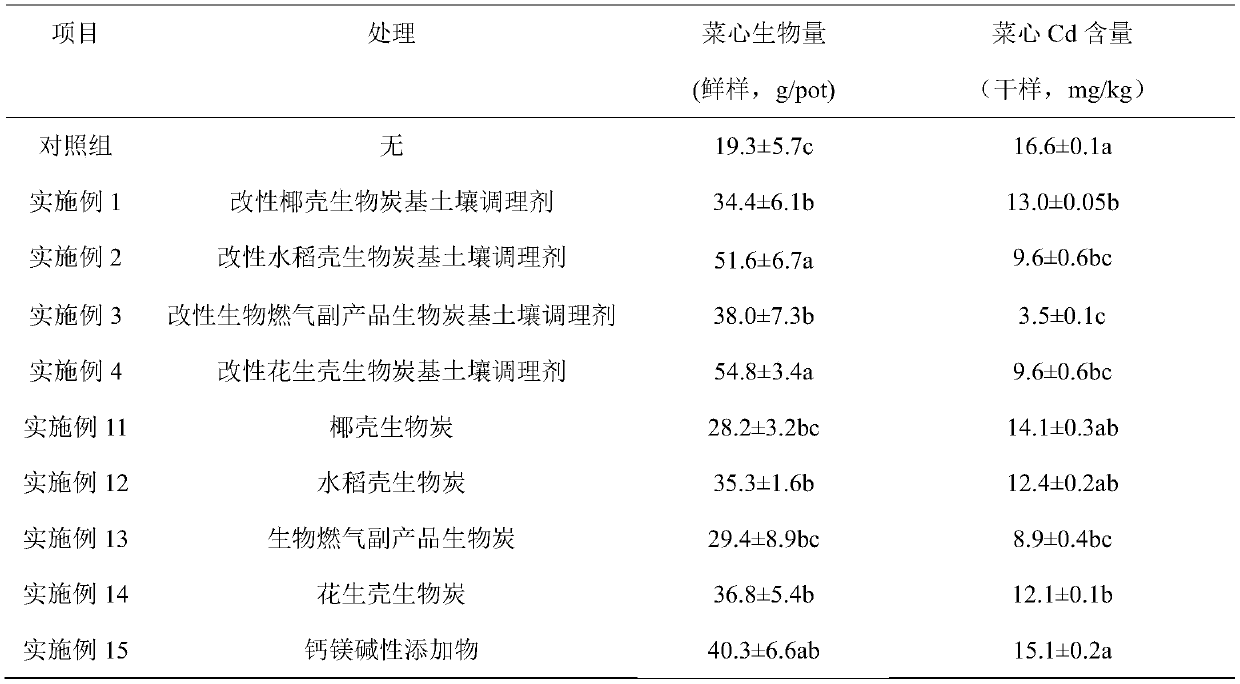

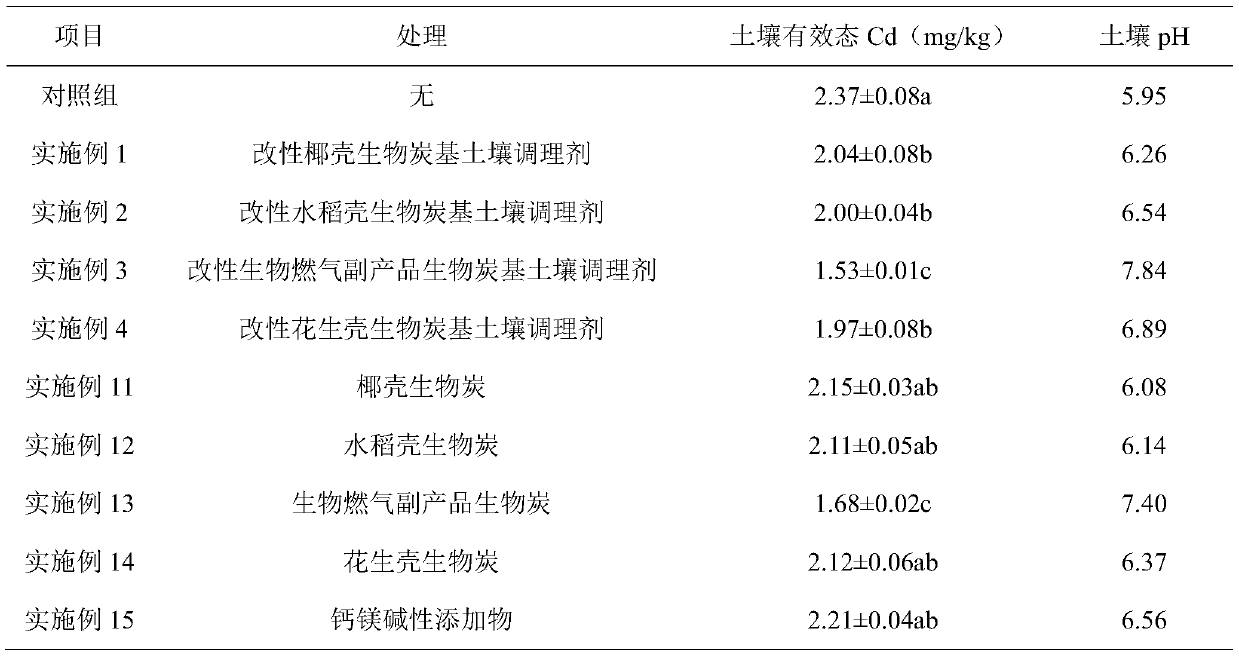

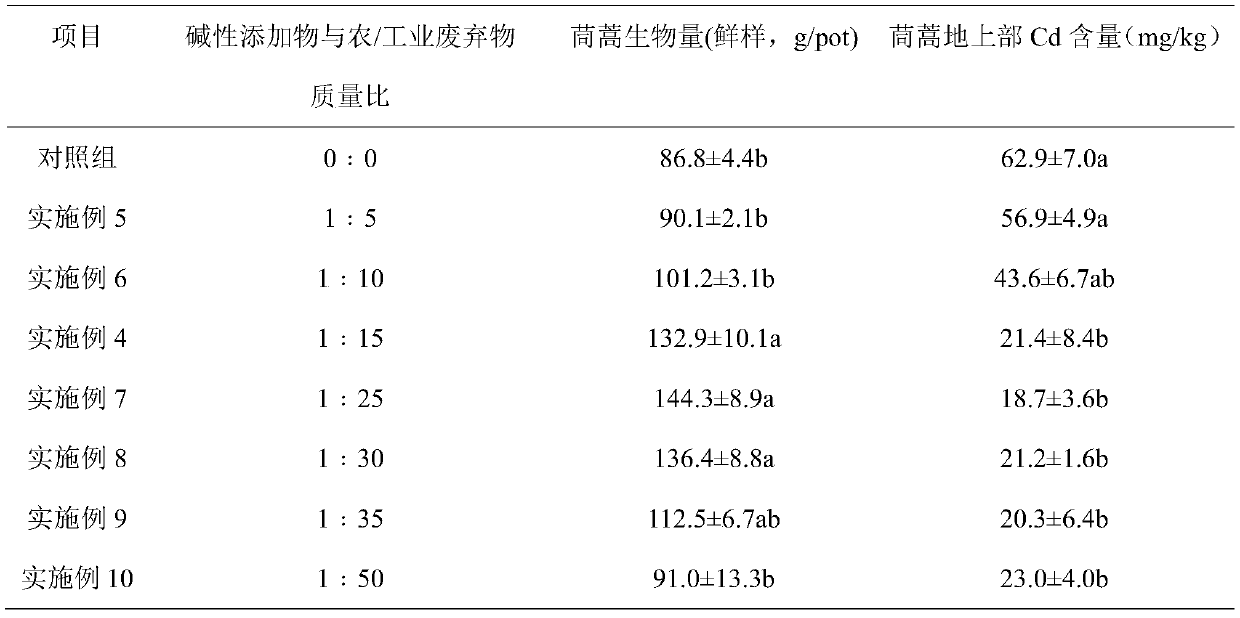

Examples

Embodiment 1

[0033] Embodiment 1: A kind of preparation method of modified biochar-based soil conditioner

[0034] Soda industrial waste residue (also known as alkali residue) is rinsed with pure water, filtered with filter paper, dried and crushed to a particle size of less than 5mm to form a coarse alkali residue product; coconut shells are dried and crushed to a particle size of less than 5mm to form coconut shell granular products. Weigh 100g of the crude alkali slag product and 1500g of the coconut shell granular material respectively, mix them well, put them into an atmosphere box furnace, and after evacuating, nitrogen gas is introduced as a protective gas, and the temperature is raised within 60 minutes at a rate of 10°C per minute to 450°C, heat-preserve for 5 hours, and then cool to room temperature to obtain the crude product of the modified coconut shell biochar-based soil conditioner. The crude product of the obtained modified coconut shell biochar-based soil conditioner is gr...

Embodiment 2

[0035] Embodiment 2: A kind of preparation method of modified biochar-based soil conditioner

[0036] Rinse the soda industrial waste slag with pure water, filter it with filter paper, dry and pulverize it until the particle size is less than 5mm to form a coarse alkali slag product; dry and pulverize the rice husk until the particle size is less than 5mm. Weigh 100g of the crude product of alkali slag and 1500g of rice husk granular material and mix them well, put them into the atmosphere box furnace, and then inject nitrogen gas as the protective gas after vacuuming, and raise the temperature to 450°C within 60 minutes at a speed of 10°C per minute. Insulate and react for 5 hours, and then cool to room temperature to obtain the crude product of the modified rice husk biochar-based soil conditioner. The crude product of the modified rice husk biochar-based soil conditioner is ground and passed through an 80-mesh sieve to obtain the modified rice husk biochar-based soil condit...

Embodiment 3

[0037] Embodiment 3: A kind of preparation method of modified biochar-based soil conditioner

[0038]Rinse the soda industrial waste residue with pure water, filter it with filter paper, dry and pulverize it until the particle size is less than 5mm to form a coarse alkali slag product; dry and pulverize the biogas by-product until the particle size is less than 5mm. Weigh 100g of the crude product of alkali slag and 1500g of the by-product granules of biogas, and mix them well, put them into the atmosphere box furnace, and after vacuuming, nitrogen is introduced as the protective gas, and the temperature is raised to 450°C within 60 minutes at a speed of 10°C per minute. , heat preservation reaction for 5 hours, and then cooled to room temperature to obtain the crude product of biochar-based soil conditioner as a by-product of modified biogas. The crude product of the modified biogas by-product biochar-based soil conditioner is ground and passed through an 80-mesh sieve to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com