Soil conditioning agent and method for reducing heavy metal Cd content in brown rice

A soil conditioner and heavy metal technology, which is applied in the field of heavy metal pollution control in paddy fields, can solve the problems of secondary pollution of soil, unstable effect and high treatment cost, and achieves the effects of restoring soil fertility, solving high treatment cost, and having a loose and porous surface structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

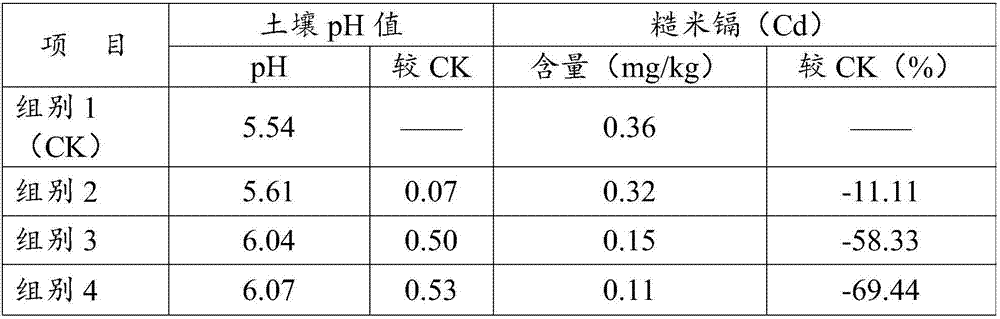

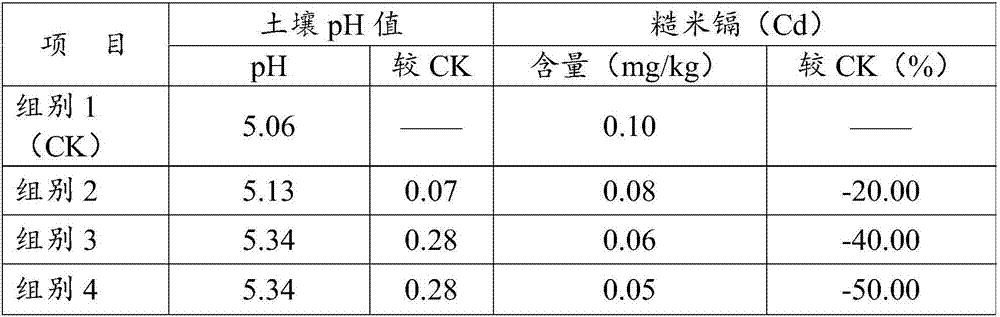

Examples

Embodiment 1

[0024] Weigh 1000kg of coconut shell, put it into an anaerobic carbonization furnace after drying it, vacuumize it and feed it with nitrogen as a protective gas, raise the temperature to 220°C at an acceleration of 6°C / min, stay for 30min, and then increase the temperature at 2°C / min After the temperature was raised to 550°C at an accelerated rate, the temperature was kept for 3 hours to obtain the intermediate carbonization product 1.

[0025] Put the intermediate carbonization product 1 into the vertical reactor, pass nitrogen into the reactor to drive away the air, start heating after 30 minutes, and raise the temperature to 900°C at a speed of 10°C / min; then, with the air flow rate of 0.45 Water vapor was passed in at L / min for activation. After activation at 900°C for 1 hour, the heating was stopped, the gas flow was switched to nitrogen, and the temperature was lowered to room temperature under the protection of nitrogen, and then vacuum-dried at 120°C for 8 hours. After...

Embodiment 2

[0029] Weigh 1000kg of palm fiber and 1000kg of sawdust, put them into an anaerobic carbonization furnace after drying, vacuumize and feed nitrogen as a protective gas, raise the temperature to 220°C at an acceleration of 6°C / min, stay for 30min, and then After heating up to 550°C at an acceleration of °C / min, the temperature was kept for 3 hours to obtain an intermediate carbonization product 2.

[0030] Put the intermediate carbonization product 2 into the vertical reactor, pass nitrogen into the reactor to drive out the air, start heating after 30 minutes, and raise the temperature to 900°C at a speed of 10°C / min; then, with the air flow rate of 0.45 Water vapor was passed in at L / min for activation. After activation at 900°C for 1 hour, the heating was stopped, the gas flow was switched to nitrogen, and the temperature was lowered to room temperature under the protection of nitrogen, and then vacuum-dried at 120°C for 8 hours. After cooling, take it out and grind it, and p...

Embodiment 3

[0034] Weigh 1000kg peanut husk and 1000kg rice husk, put them into an anaerobic carbonization furnace after drying, and pass nitrogen as a protective gas after vacuuming, raise the temperature to 220°C at an acceleration of 6°C / min, stay for 30min, and then After heating up to 550°C at an acceleration of 2°C / min, the temperature was kept for 3 hours to obtain the intermediate carbonization product 3.

[0035] Put the intermediate carbonization product 3 into the vertical reactor, feed nitrogen into the reactor to drive out the air, start heating after 30 minutes, and raise the temperature to 900°C at a rate of 10°C / min; then, with the air flow rate of 0.45 Water vapor was passed in at L / min for activation. After activation at 900°C for 1 hour, the heating was stopped, the gas flow was switched to nitrogen, and the temperature was lowered to room temperature under the protection of nitrogen, and then vacuum-dried at 120°C for 8 hours. After cooling, take it out and grind it, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com