Automatic machine tool cutting fluid recovery processor

A cutting fluid and processor technology, applied in lubricating compositions and other directions, can solve the problems of increased cutting fluid consumption cost, bacterial proliferation, waste of cutting fluid resources, etc., and achieve the effect of reducing enterprise cost consumption, simplifying recycling process, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

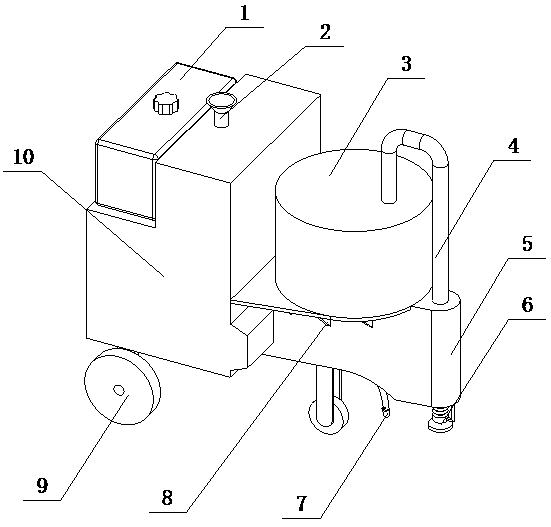

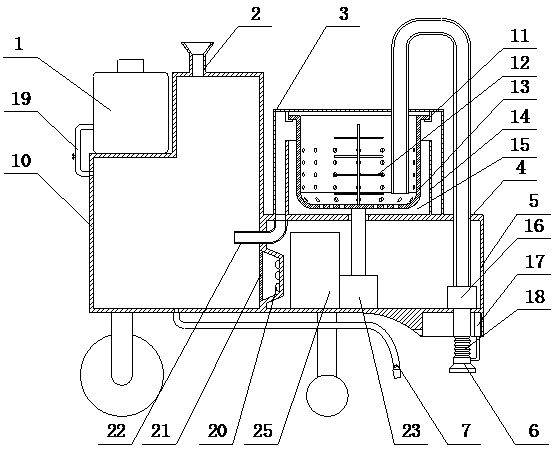

[0021] The automatic machine tool cutting fluid recovery processing machine of the present invention is realized in this way: the automatic machine tool cutting fluid recovery processing machine of the present invention is composed of a separation device and a sterilizing device, and the separation device is composed of a centrifugal sedimentation box (3), a connecting pipe (4), and a driving box ( 5), suction pipe (6), reinforcement rib (8), limit ring (11), stirring blade (12), centrifugal cylinder (13), partition (14), sedimentation chamber (15), liquid suction pump (16), electric telescopic rod (17), corrugated telescopic tube (18), driving motor (23) and buckle groove (24), the centrifugal sedimentation box (3) is placed on the driving box (5), and the centrifugal A reinforcing rib (8) is placed between the settling box (3) and the driving box (5), the liquid suction pump (16) is placed in the driving box (5), and one end of the liquid outlet pipe (22) and the liquid sucti...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is: the sterilization box (10) has a plurality of stirring rollers (26) built in; when in use, the plurality of stirring rollers (26) stir the cutting fluid to improve the mixing adjustment of the cutting fluid speed;

[0027] The design of reinforcing ribs (8) placed between the centrifugal sedimentation box (3) and the driving box (5) makes the overall structure of the device stable;

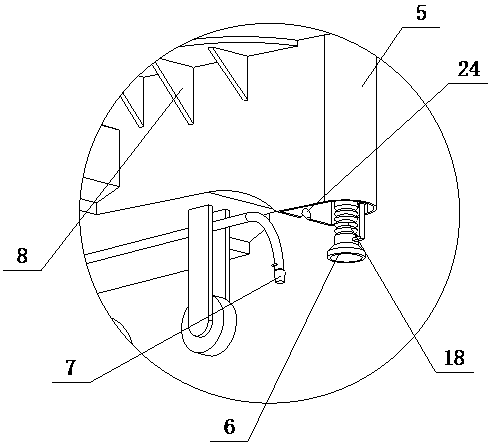

[0028] The diameter of the lower section of the suction pipe (6) is designed to be larger than the diameter of its upper end, so that the contact area between the suction pipe (6) and the cutting fluid is large, and the suction effect on the cutting fluid is good;

[0029] The connection between the upper section and the lower section of the suction pipe (6) is designed as a slope, which makes the suction and delivery of the cutting fluid by the suction pipe (6) smooth and reduces resistance;

[0030] The design of the gasket betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com