Low-fluorine slag system for electroslag remelting of b-containing 9cr rotor steel ingot and its application method

A technology for electroslag remelting and rotor steel, which is applied in the field of electroslag special metallurgy, can solve the problems of unenvironmental protection, high energy consumption of smelting slag, and unstable smelting, and achieves the advantages of reducing burning loss, power consumption and good energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention are specifically described below, and the embodiments of the present invention are used to explain the principle of the present invention, but not to limit the scope of the present invention.

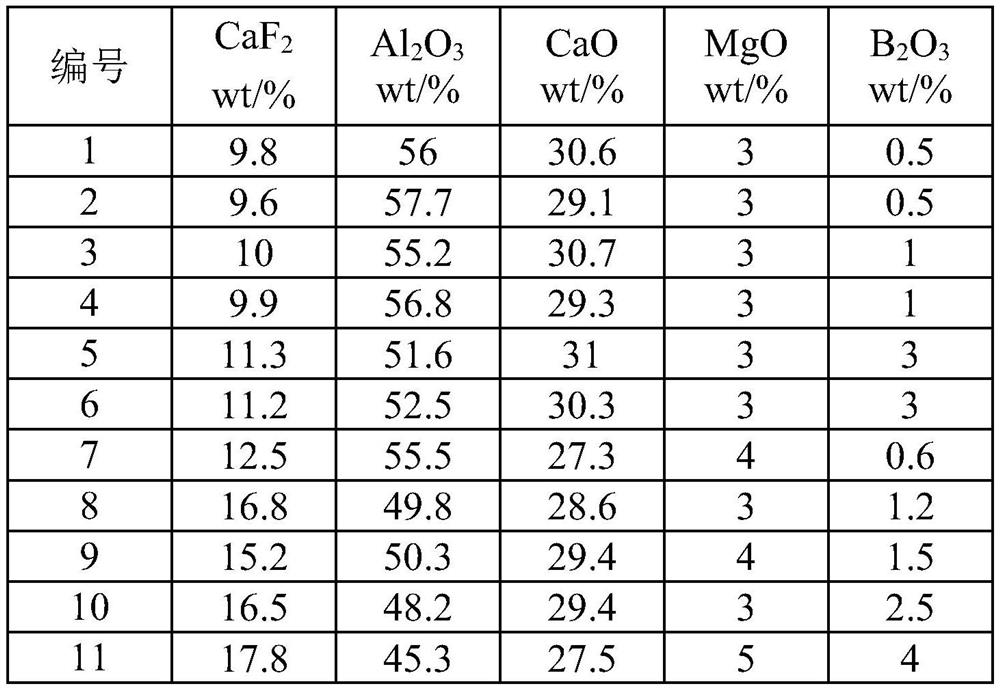

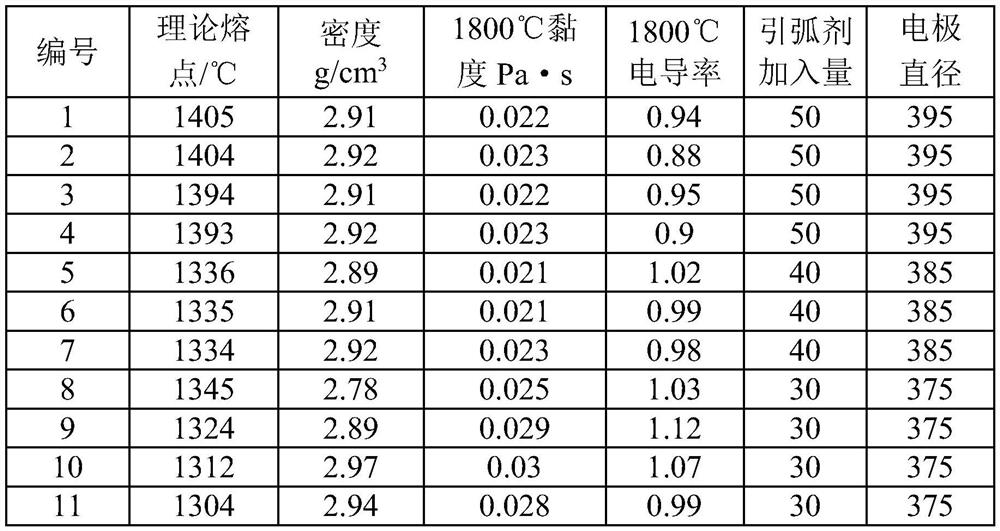

[0025] The object of the present invention is to provide a low-fluorine slag system for electroslag remelting of B-containing 9Cr rotor steel ingots and its application method. Based on the thermodynamic phase diagram, the content of each component in the slag system is calculated according to the temperature range of the slag system design. The obtained slag system has a stable composition structure, which can balance the easy-to-burn B elements in the steel slag, and has the advantages of energy saving and other advantages. Difficult technical requirements for electroslag smelting of 9Cr high-pressure rotor steel containing B, providing technical support for electroslag smelting of new materials.

[0026] On the one hand, the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com