Chemical fiber textile material forming device

A textile material and chemical fiber technology, which is applied in the field of chemical fiber textile material forming devices, can solve the problems of reducing the processing efficiency of textile materials and affecting the processing speed of textile materials, and achieve the effects of avoiding waste, ensuring cleanliness, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

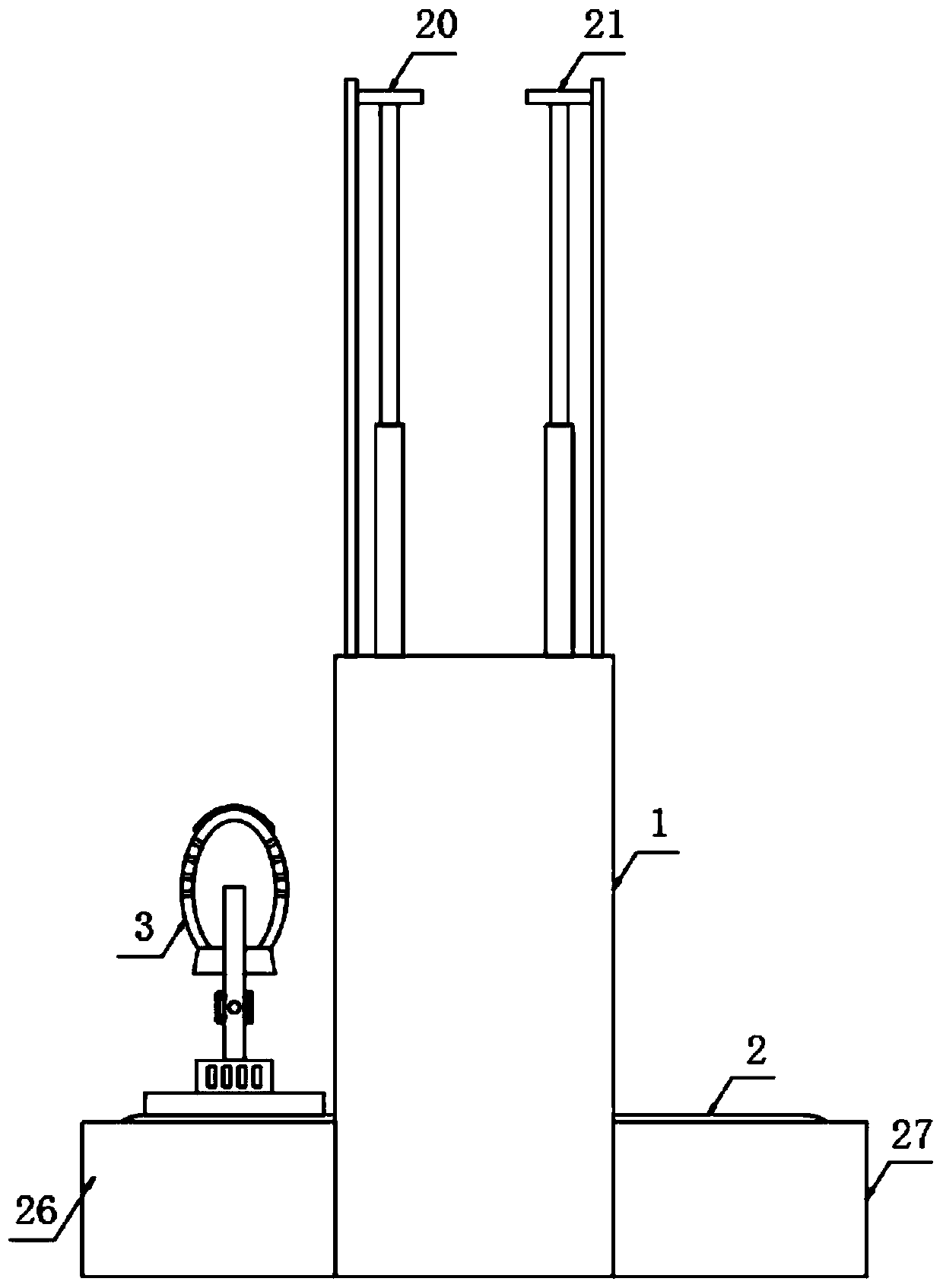

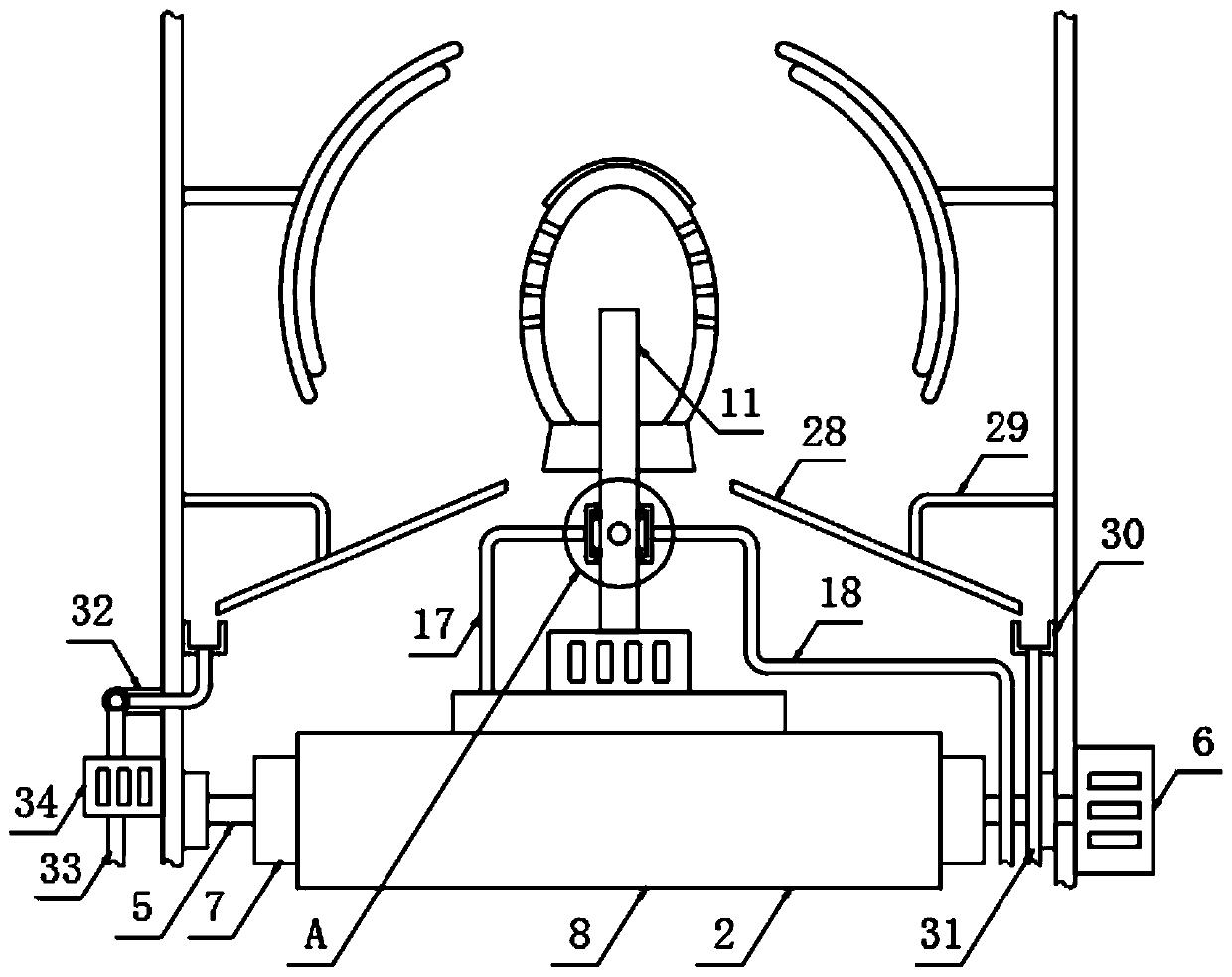

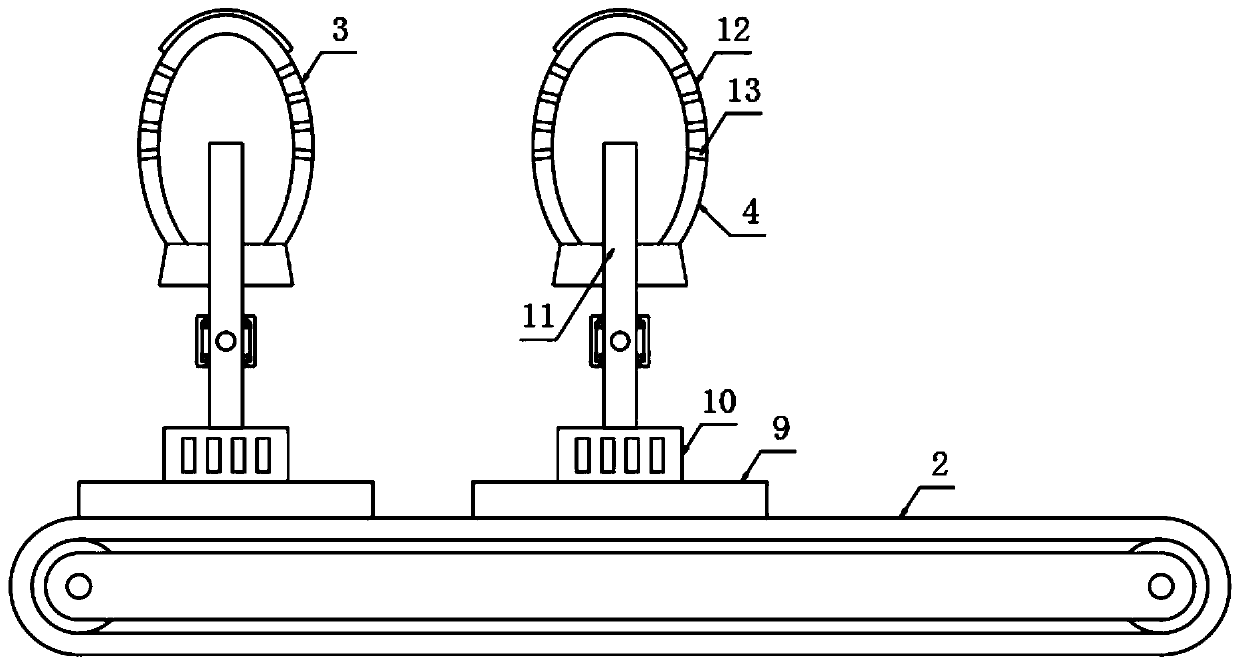

[0037] The specific embodiment is: the present invention is provided with the first sealing mechanism 20 and the second sealing mechanism 21, so that in the process of processing, the cylinder 22 in the first sealing mechanism 20 and the second sealing mechanism 21 can be started, and then the cylinder can be used to 22 drives the connecting plate 23 to descend. During the descending process of the connecting plate 23, it will drive the sealing glass 24 to descend synchronously along the inner side of the sealing ring 25, so that the sealing glass 24 in the first sealing mechanism 20 and the second sealing mechanism 21 aligns with the central casing. 1. The front side and the rear side are sealed, so as to prevent the chemical liquid on the textile material from being thrown out during the rotation process, and the situation of splashing everywhere occurs, which ensures the cleanliness of the working environment.

[0038] as attached figure 2 with attached Figure 5 The chem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap