Face rockfill dam seepage prevention structure

A face rockfill dam and face face technology, which is applied in dams, barrages, water conservancy projects, etc., can solve the problems of inconvenient operation and maintenance, easy separation from the downstream cushion area, affecting the anti-seepage function of face plates, etc., so as to improve the mechanical performance and prevent Seepage effect, improve anti-seepage effect and safety, prevent upstream floating objects from puncturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

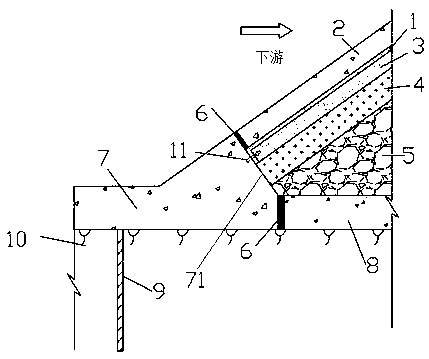

[0028] Such as figure 1 As shown, the anti-seepage structure of a face rockfill dam provided in this embodiment includes a bedrock 10 and a plinth 7 located on the bedrock 10, and the downstream side of the plinth 7 is arranged to be flush with the plinth 7. The anti-seepage layer 8. A rockfill material 5 , a transition layer 4 , a cushion material 3 , a geomembrane 1 and a panel 2 are sequentially arranged upward from the anti-seepage layer 8 , and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com