Supporting structure and plugging sleeve structure for anchor rod gap grouting

A technology for supporting structures and bolts, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of quality and safety hazards, bolt leakage, endangering engineering construction safety, etc. Reliability, grouting material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

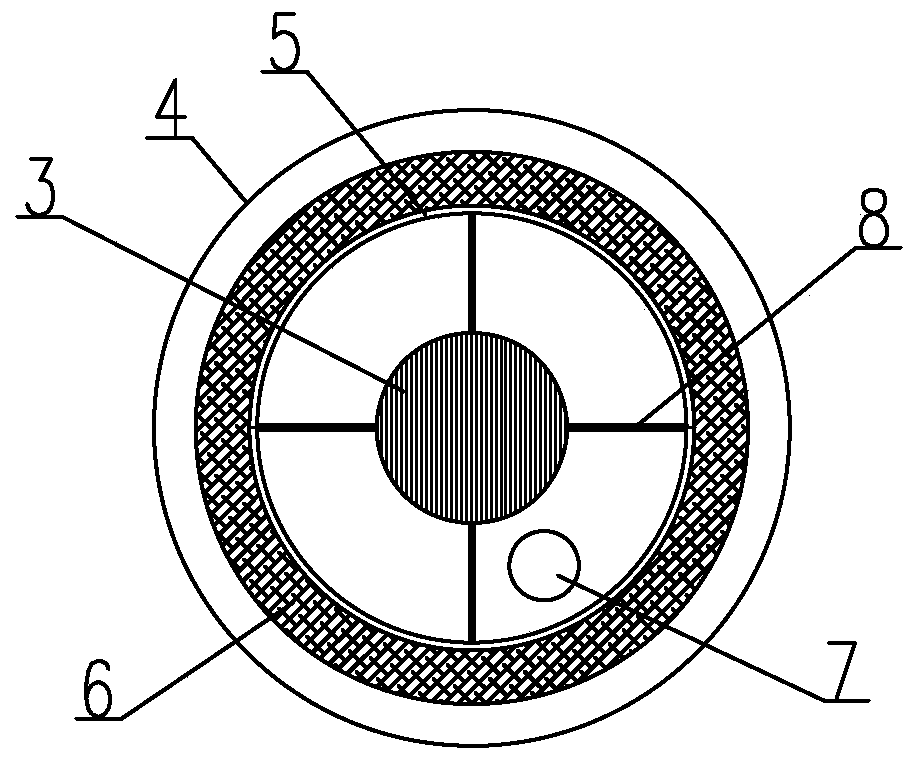

[0016] Embodiments of the present invention are:

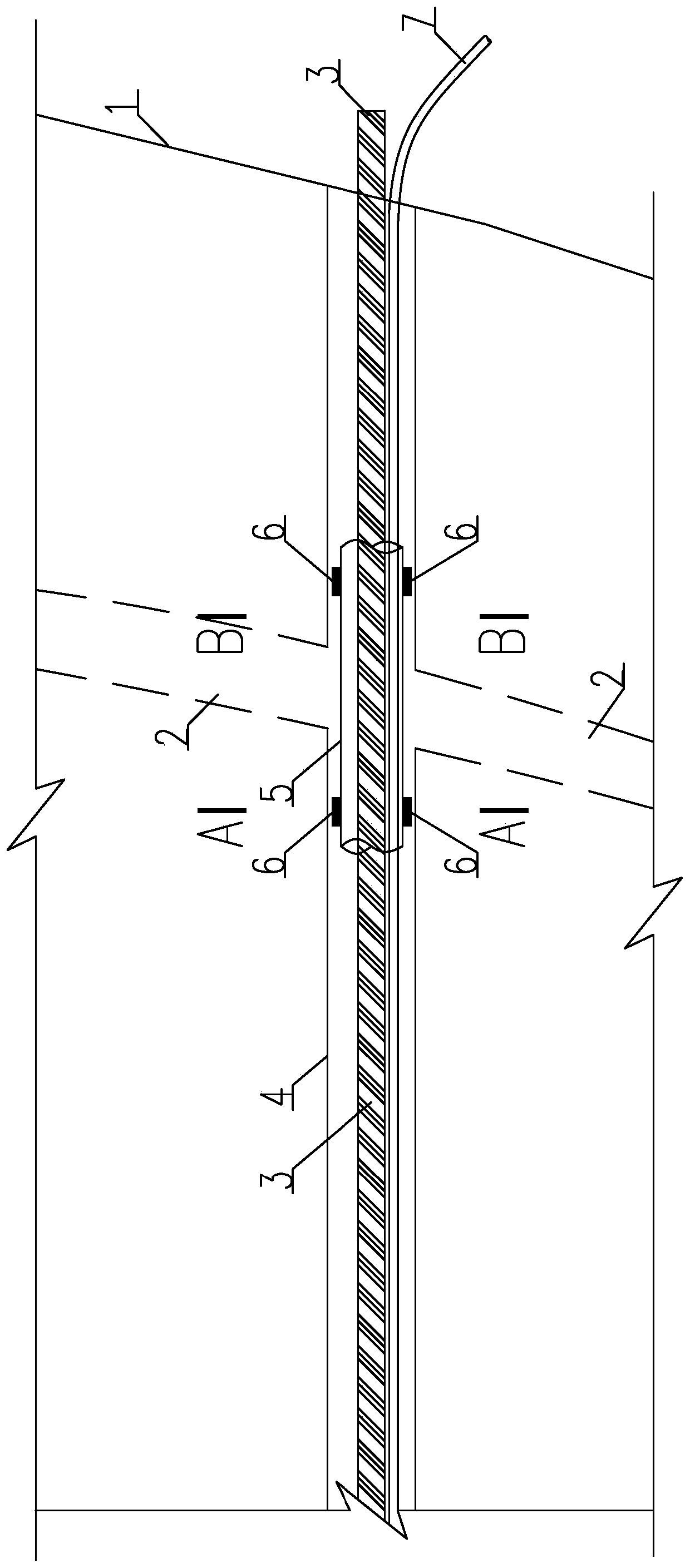

[0017] During the bolt drilling construction process, abnormal situations such as drill drop and non-return wind occurred, and the drilling records were made in time. After the drilling was completed, the drilling camera equipment was used to detect large internal cracks, and a detailed map of the crack location was drawn. Then the plugging structure of the present invention is installed at the position corresponding to the occurrence of cracks in the anchor rod. Or, if there is a huge amount of grout and no grout return during grouting, the bolt should be withdrawn in time and the plugging structure of the present invention should be adopted.

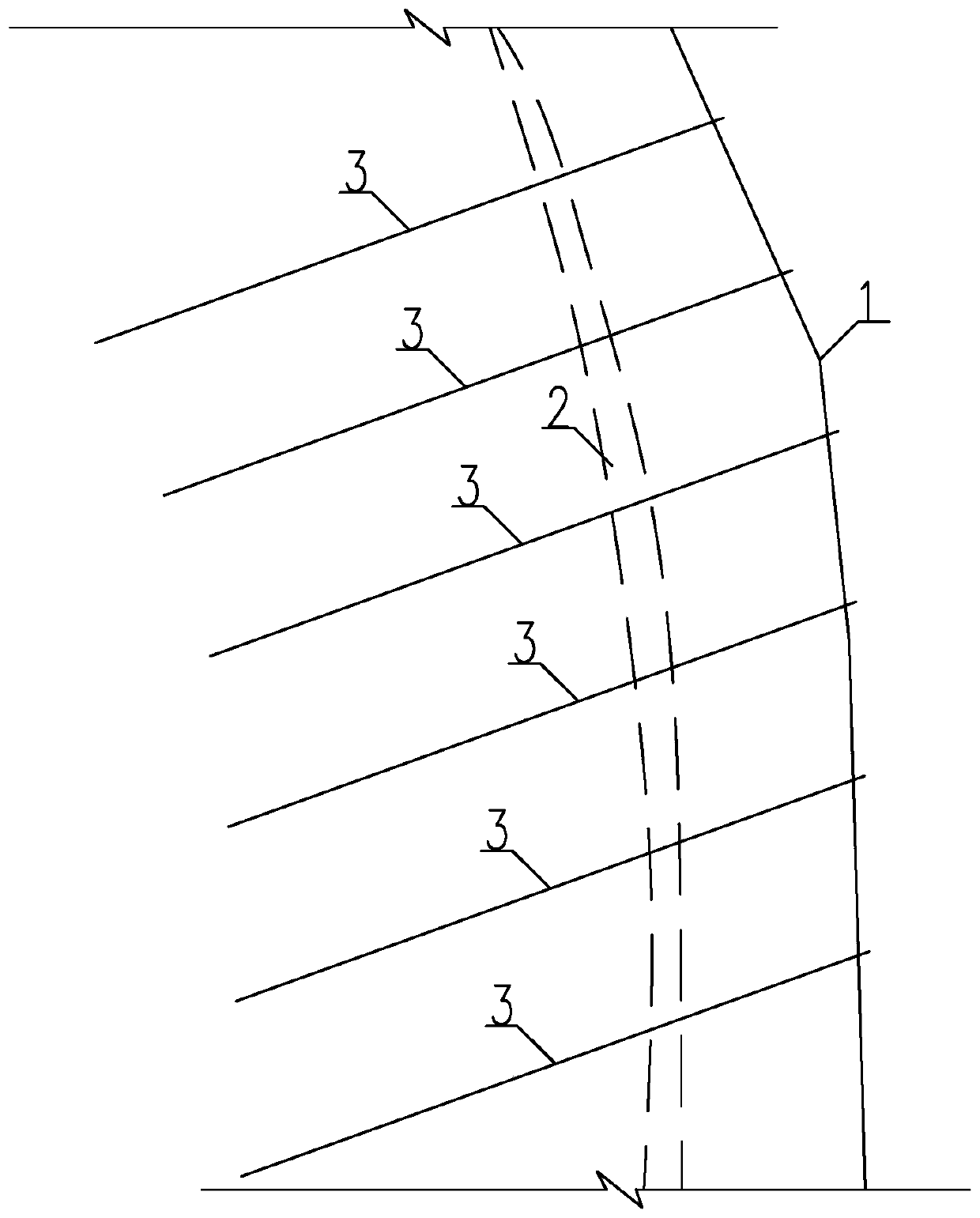

[0018] like figure 1 As shown, reinforcement treatment is required for the dangerous rock mass 1. However, during the grouting process of the support bolt 3, a large amount of grout was consumed and there was no grout return. A fissure 2 with a width of about 0.3m was found at about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com