High-pressure jet grouting pile foundation reinforcement construction method

A technology for high-pressure rotary jetting piles and foundation reinforcement, which is applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve the problems of fast groundwater flow rate, large sand permeability coefficient, and wash away, and achieves low construction costs and reduced costs. The effect of engineering technology risk and construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

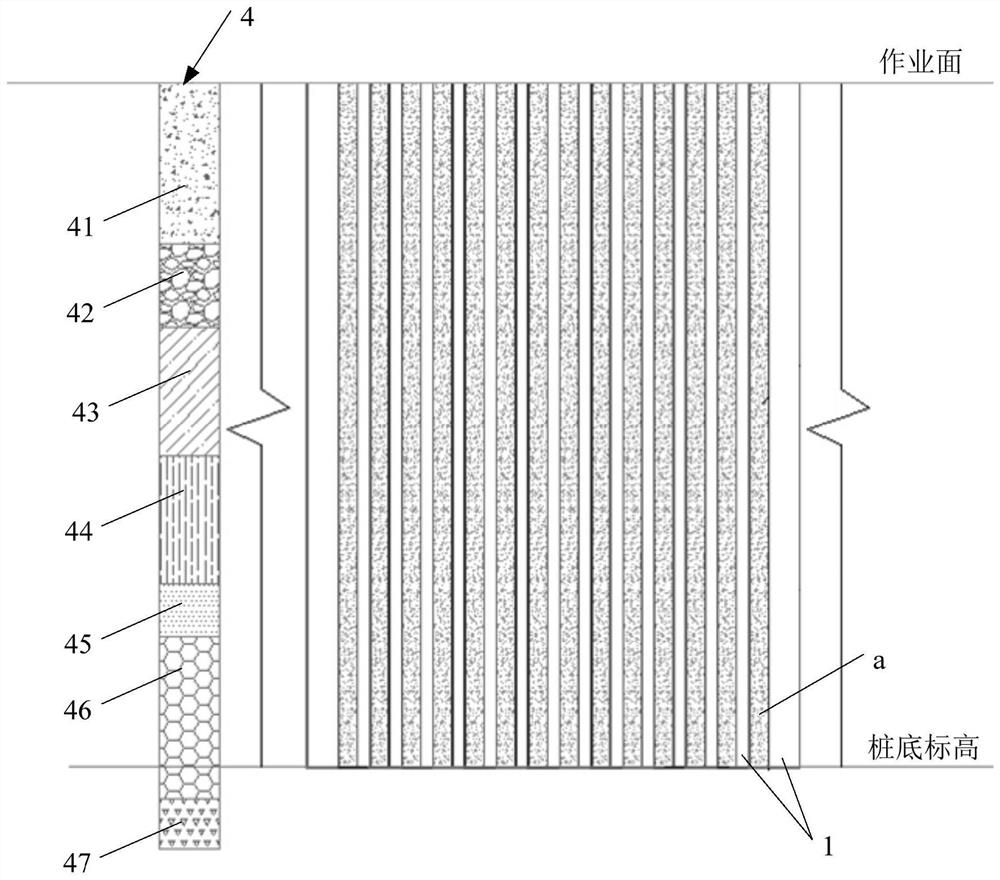

[0025] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

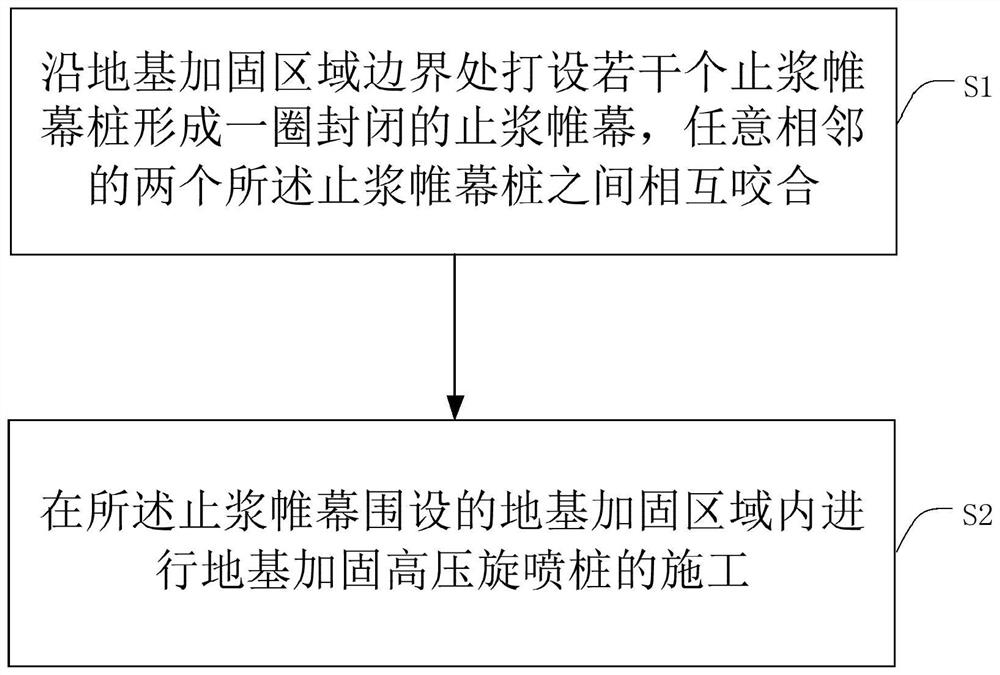

[0026] see figure 1 , the present invention provides a kind of construction method of high-pressure rotary grouting pile foundation reinforcement, and this construction method comprises the following steps:

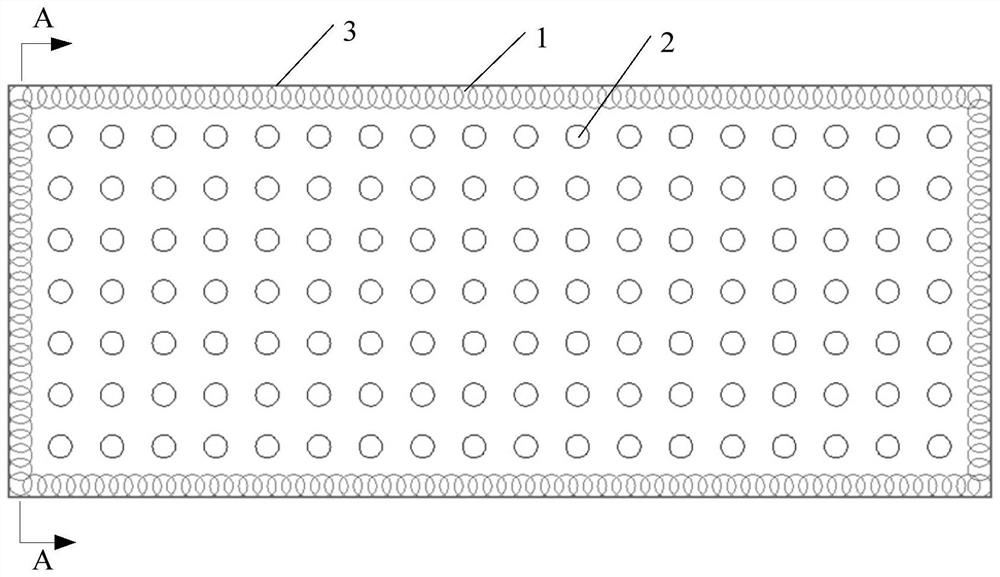

[0027] Step S1: setting up several grout-stop curtain piles along the boundary of the foundation reinforcement area to form a circle of closed grout-stop curtains, and any two adjacent grout-stop curtain piles are engaged with each other.

[0028] In this step, before the construction of the grout-stop curtain pile, the pile bottom elevation of the grout-stop curtain pile must be determined according to the layer thickness and layer height of each layer of rock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com