A tunnel inverted arch foundation reinforcement component and construction method

A technology of foundation reinforcement and construction method, which is applied in basic structure engineering, construction, soil protection and other directions, can solve the problems such as the late time for the tunnel support structure to be closed into a loop, the difficulty in erecting punching equipment, and the occupation of the initial support time of the inverted arch. , to achieve the effect of ensuring the quality of foundation reinforcement, simple structure and easy grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

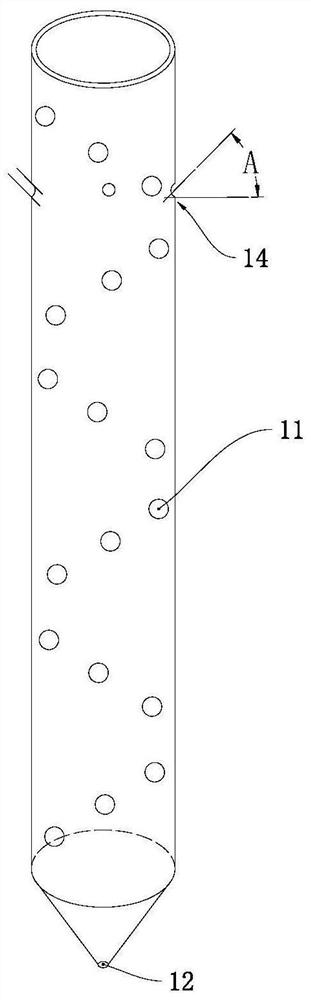

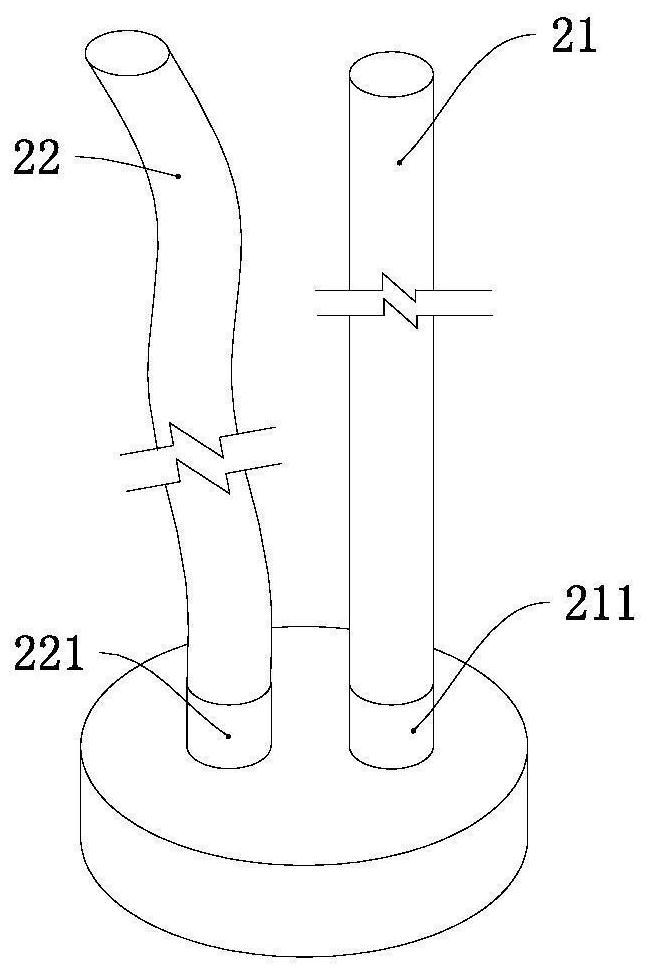

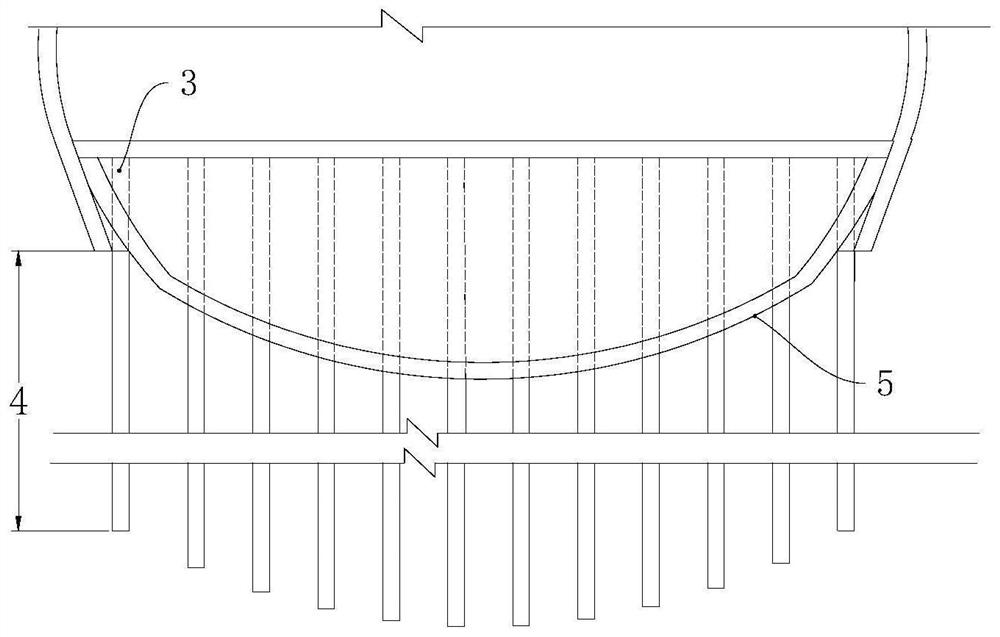

[0046] A tunnel inverted arch foundation reinforcement component is characterized in that it includes: multi-section steel flower tubes 1 and steel covers 2, and multi-section steel flower tubes 1 are fixedly connected in sequence along the vertical direction, referring to figure 1 , the upper end of the steel flower tube 1 located at the lowermost end in the vertical direction is open and the lower end is closed. The pipe wall of the steel flower tube 1 is respectively provided with a plurality of grouting holes 11. The lower end of the steel flower pipe 1 is provided with a bottom grouting hole 12, and the bottom grouting hole 12 aperture is 5cm, and the length of the steel flower pipe 1 is not greater than the height from the top wall of the tunnel to the ground. In this embodiment, the length of the steel flower pipe 1 is 6m. A plurality of uniformly distributed fixing holes 14 are arranged on the outer wall of the steel flower tube 1 that is 1m from the top of the steel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com