Hill sand inorganic grouting material, preparation and construction method thereof

A construction method and grouting material technology, applied in the field of building grouting materials, can solve the problems of high temperature resistance of cementitious materials, complex construction process, poor durability, etc., and achieve the effects of low cost, good durability and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

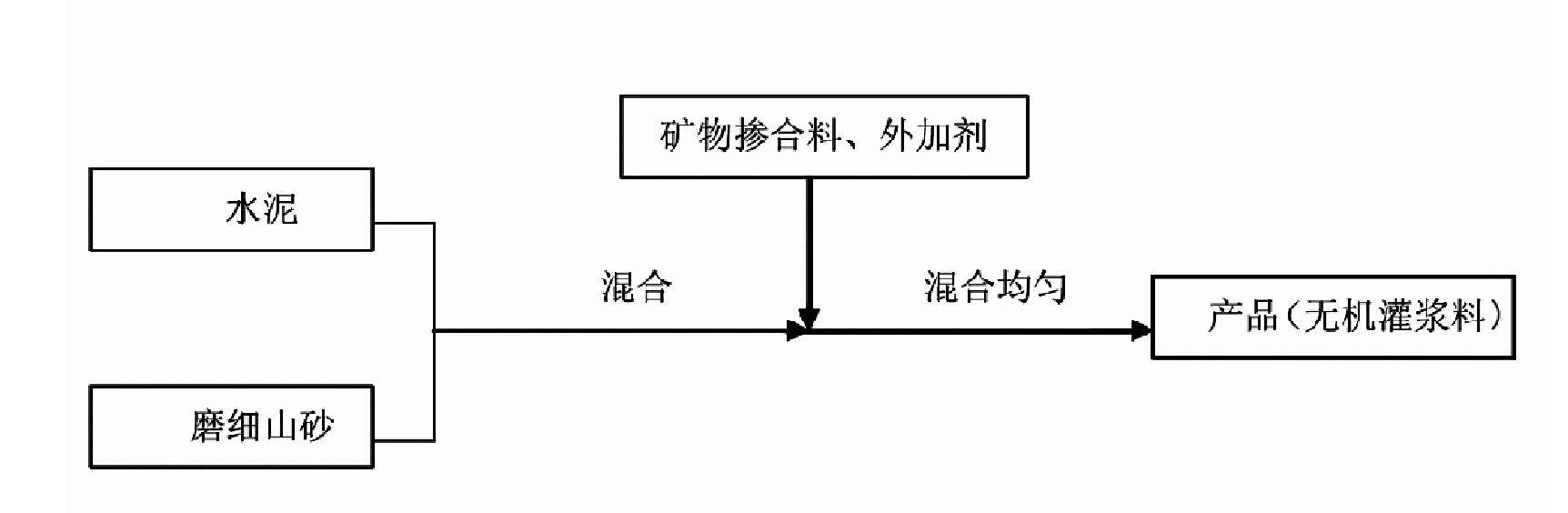

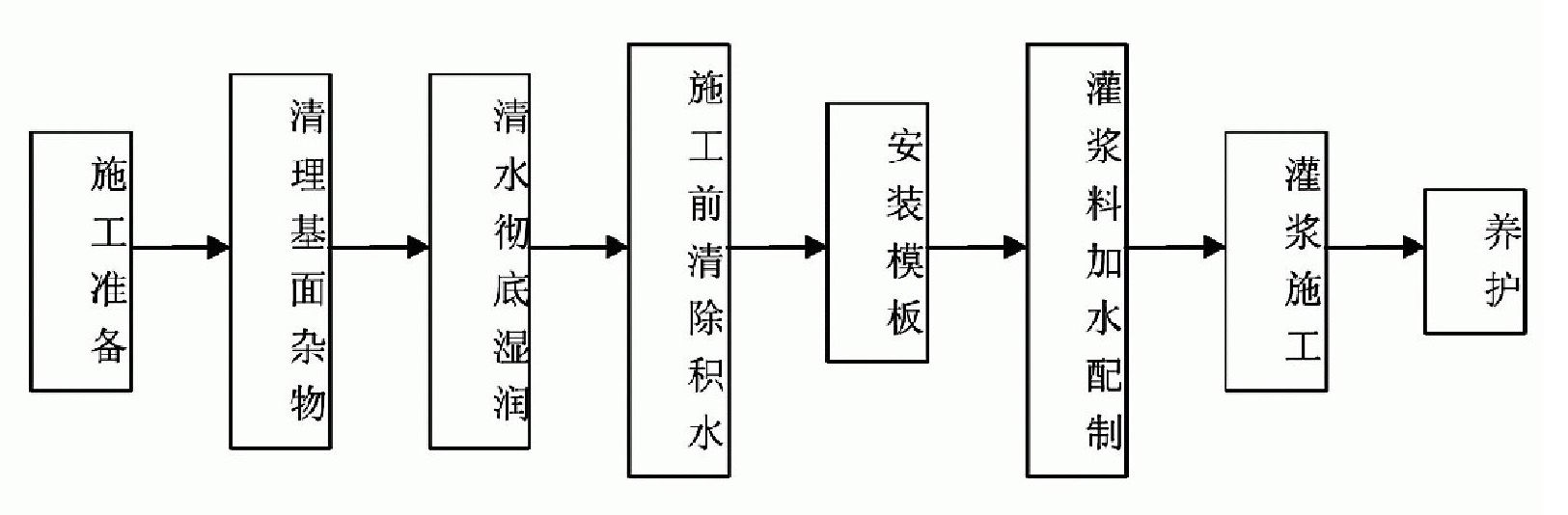

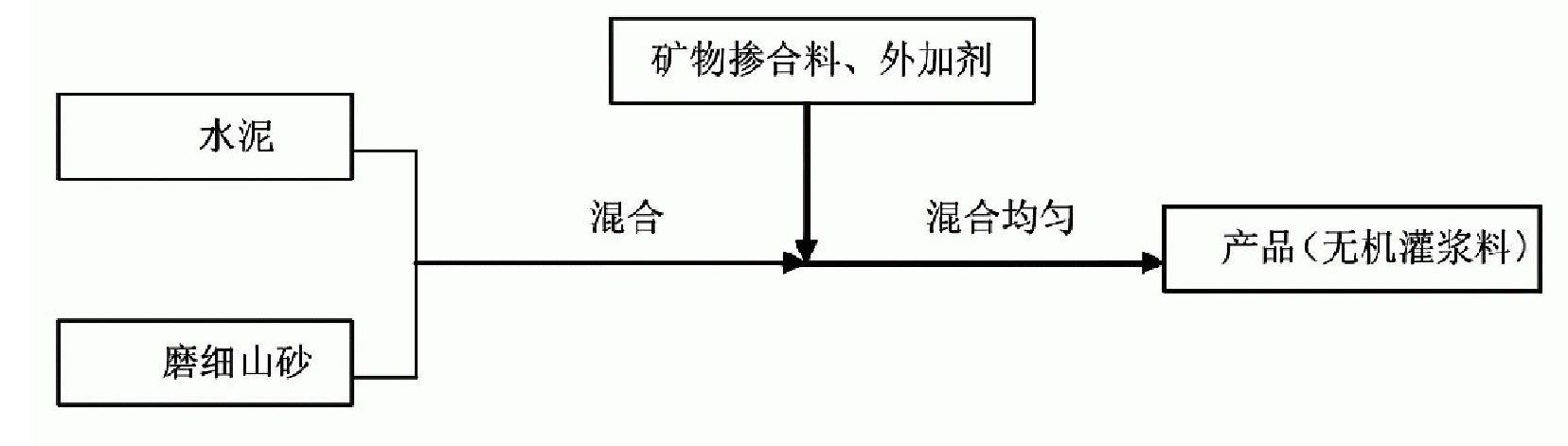

[0039] Embodiment: a kind of mountain sand inorganic grouting material, including sand, cementitious material and admixture, it is characterized in that: the above-mentioned sand is finely ground mountain sand, the above-mentioned cementitious material is cement and phosphate rock powder, and the above-mentioned admixture is an expansion agent and water reducing agent, the above materials are formulated according to the following weight ratio:

[0040] 1 part finely ground mountain sand;

[0041] 1 part of cement;

[0042] Phosphate rock powder 0.02~0.04 parts;

[0043] Expanding agent 0.07~0.10 parts;

[0044] Water reducing agent 0.007~0.010 parts.

[0045] The raw material performance index that the present invention adopts is as follows:

[0046] The above-mentioned ground mountain sand has a particle diameter of 2.5 mm or less.

[0047] The above cement is 42.5 ordinary Portland cement, sulphoaluminate cement or slag cement.

[0048] Cement inspection results

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com