Large venue steel structure support dismounting device and construction method

A technology of unloading device and steel structure, which is applied to pillars, building structures, and on-site preparation of building components, etc., can solve problems such as inconvenient unloading of steel structure support, and achieve rapid assembly and disassembly, convenient erection, and highly accurate support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

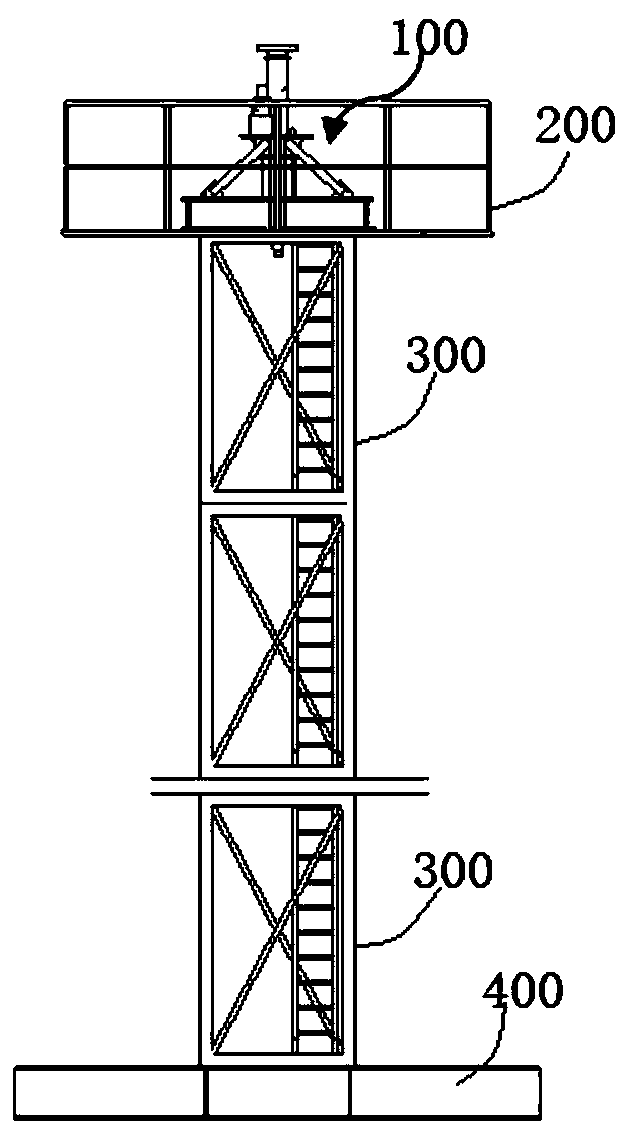

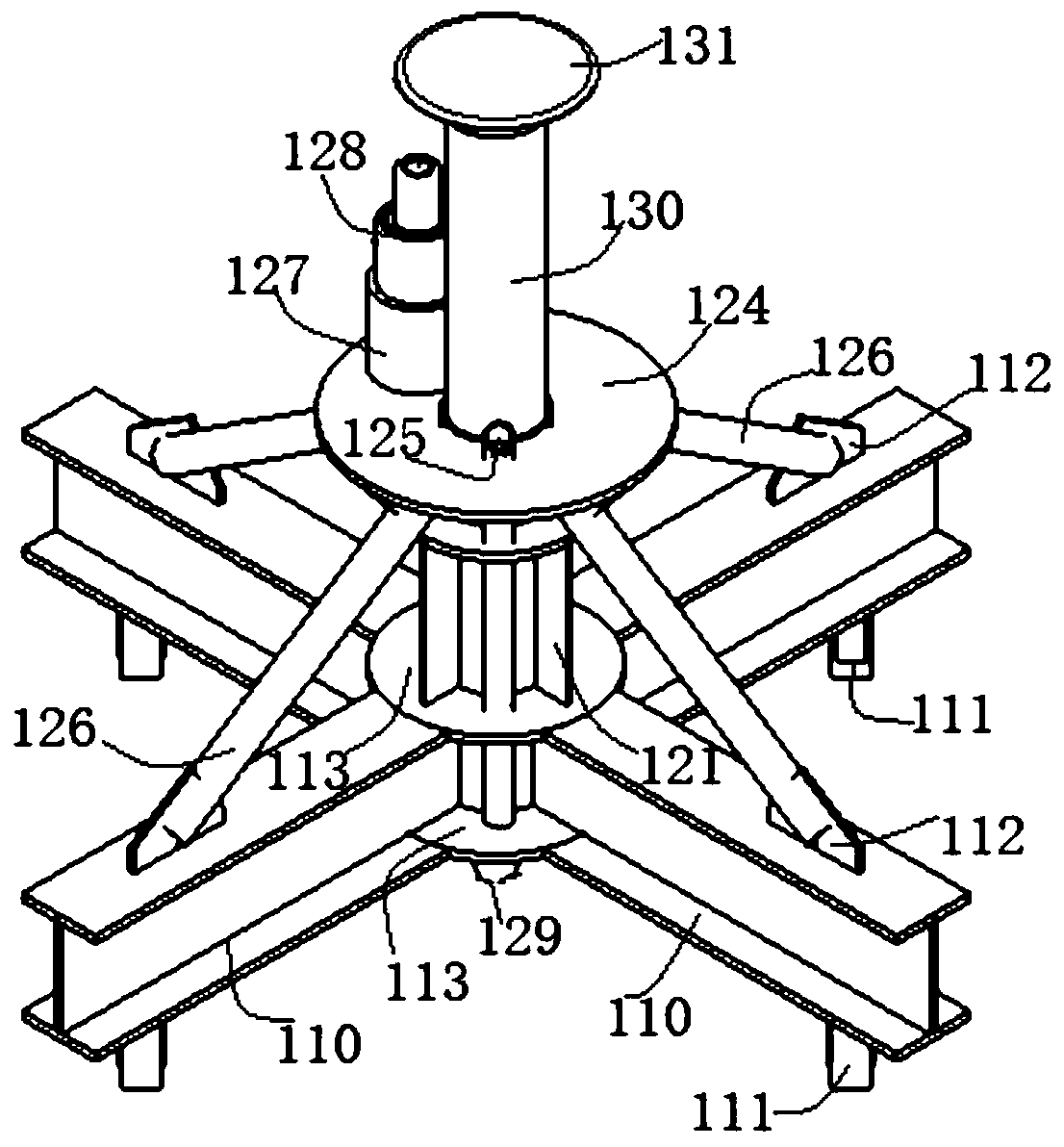

[0048] Such as Figure 1-Figure 5 As shown, a large stadium steel structure support unloading device in this embodiment includes a sand steel unloading unit 100. The sand steel unloading unit 100 includes a steel base 110 and a sand cylinder outer cylinder 120. The sand cylinder outer cylinder 120 is a hollow cylinder. body and the bottom passes through the shaped steel base 110, and the bottom end of the outer cylinder body 120 of the sand tank is provided with a ball valve 129, specifically a high-pressure ball valve can be used; the outer cylinder body 120 of the sand tank is also provided with an inner cylinder body 130 of the sand tank, and The cylinder gap between the cylinder body 120 and the cylinder body 130 in the sand cylinder is used for filling fine sand, and the top of the cylinder body 130 in the sand cylinder is provided with a top seat 131; the top of the cylinder body 120 outside the sand cylinder is provided with a cylinder body platform 124, and On the body...

Embodiment 2

[0053] The supporting and unloading device for a large-scale stadium steel structure in this embodiment is basically the same as that in Embodiment 1. Furthermore, the steel base 110 is composed of two sets of H-shaped steels interlaced in a cross shape, and is firmly connected by welding to form an assembled base. The cross position of the H-shaped steel is provided with upper and lower two layers of reinforcement plates 113, and the two layers of reinforcement plates 113 are respectively located on the top and bottom surfaces of the intersection positions, and the reinforcement plates 113 are composed of a plurality of fan-shaped plates, and each fan-shaped reinforcement plate 113 will Adjacent H-shaped steel walls are connected to form an overall circular reinforced plate shape at the top and bottom surfaces to enhance the connection strength between the shaped steels. The shaped steel base 110 and the assembled standard support segment 300 can also be socketed. The shaft pi...

Embodiment 3

[0058] A construction method of a steel structure support and unloading device for a large venue in this embodiment includes the following steps:

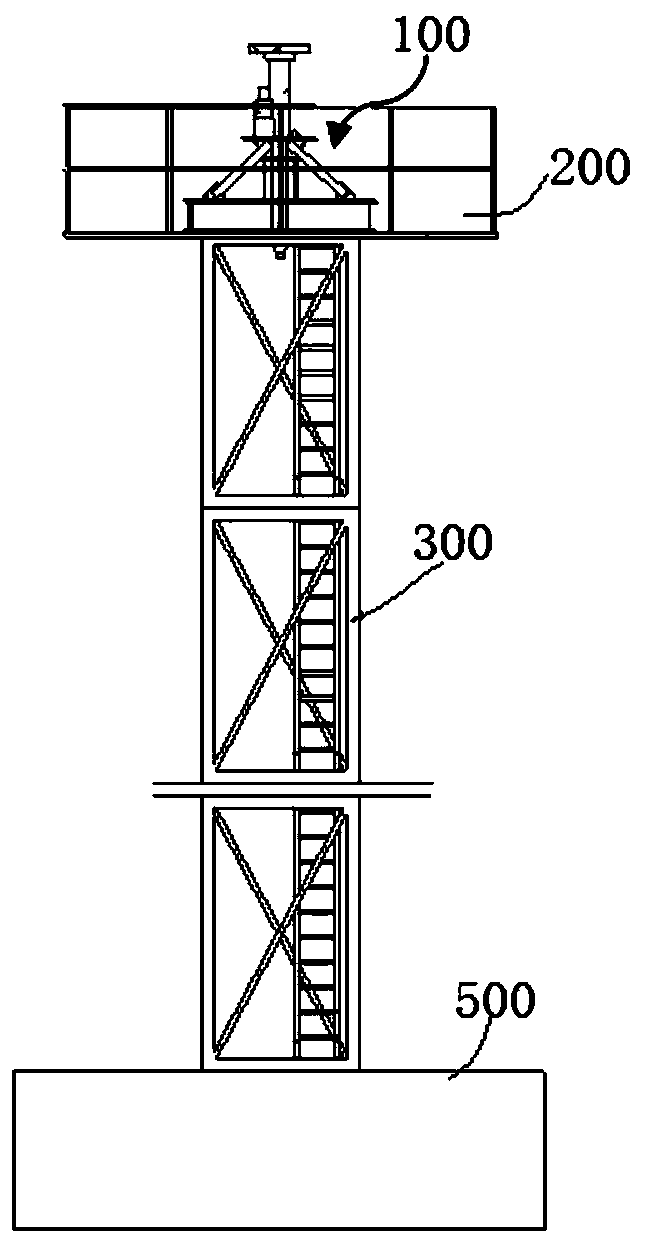

[0059] S1. After the construction of the civil structure of the large-scale venue is completed, the steel structure construction starts, and the supporting foundation is installed first. The supporting foundation adopts a steel assembly base 400 or a pre-embedded concrete 500;

[0060] S2. Install the assembled standard support section 300. The number of installation sections is determined according to the height of the steel structure that needs to be supported and unloaded. Each assembled standard support section 300 is connected by a socket-type pivot pin, and the sand steel unloading unit 100 is reserved for the upper part. Installation height; the assembled standard support segment 300 used in this embodiment can be disassembled quickly, the specification can be 1m or 2m, the bearing load is large, and any height combination wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap