Ultrasonic suspension hub bearing for electric automobile

A technology for hub bearings and electric vehicles, which is applied to rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of not using electric vehicles, achieve low replacement costs, strong environmental adaptability, and reduce frictional heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

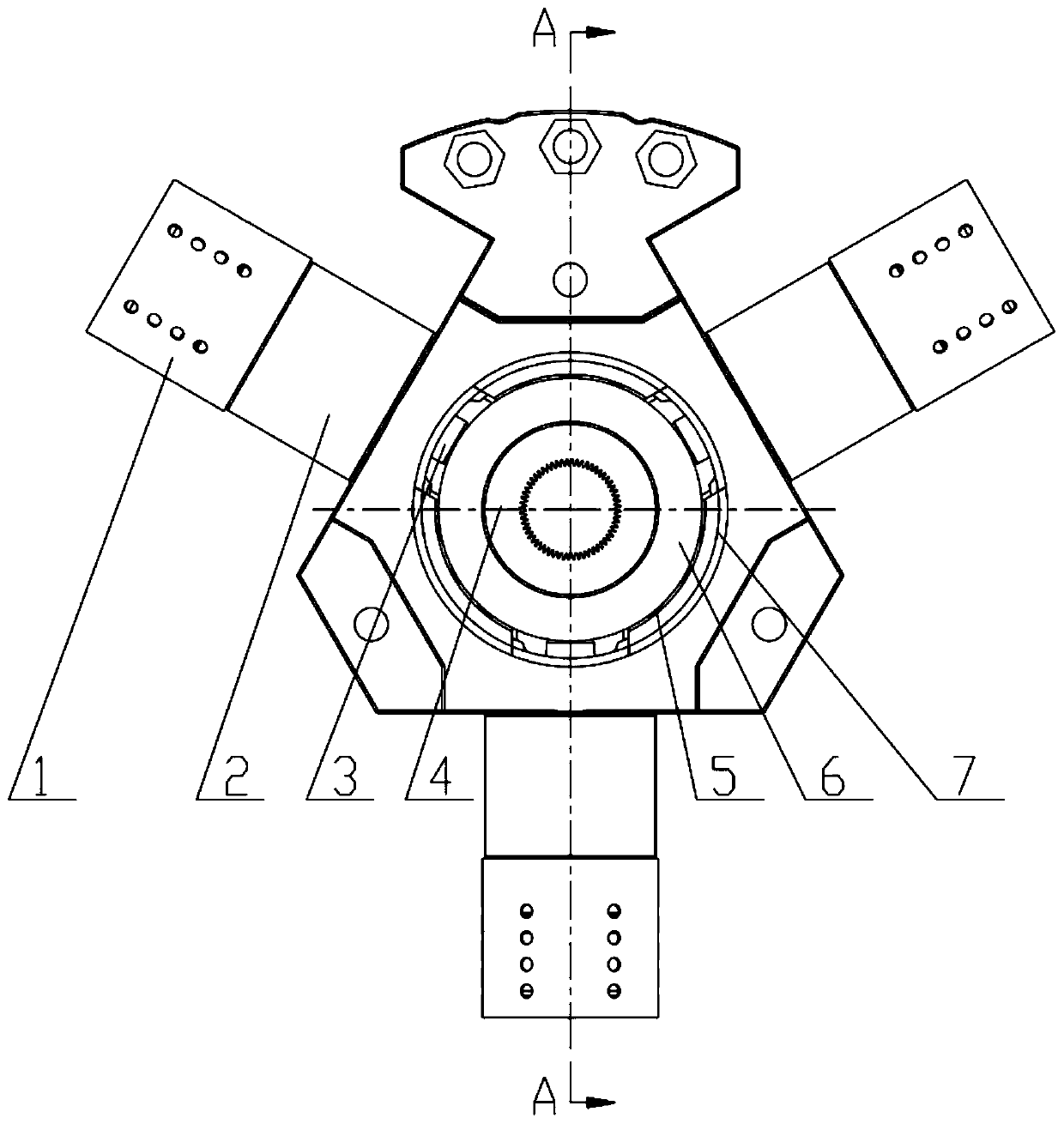

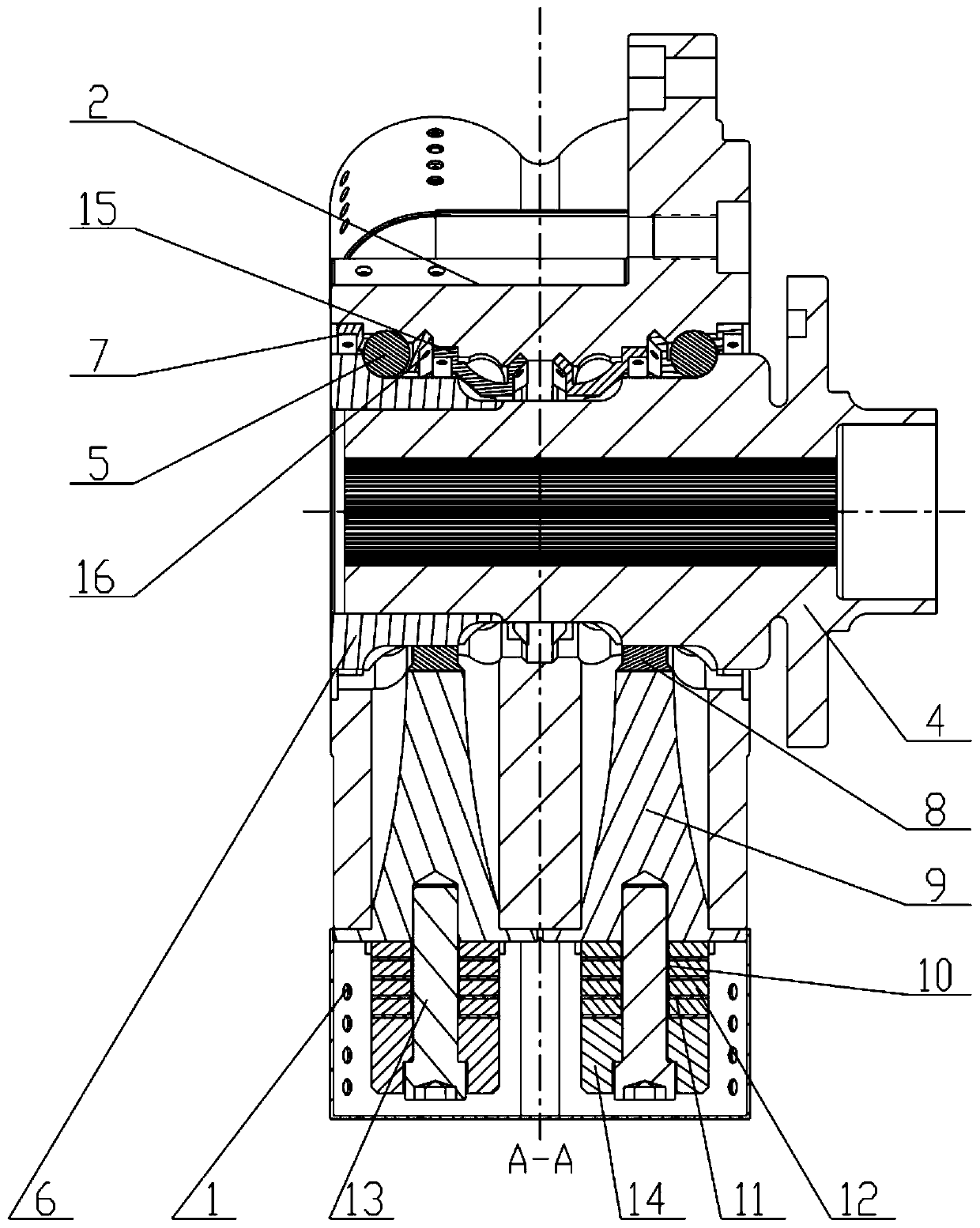

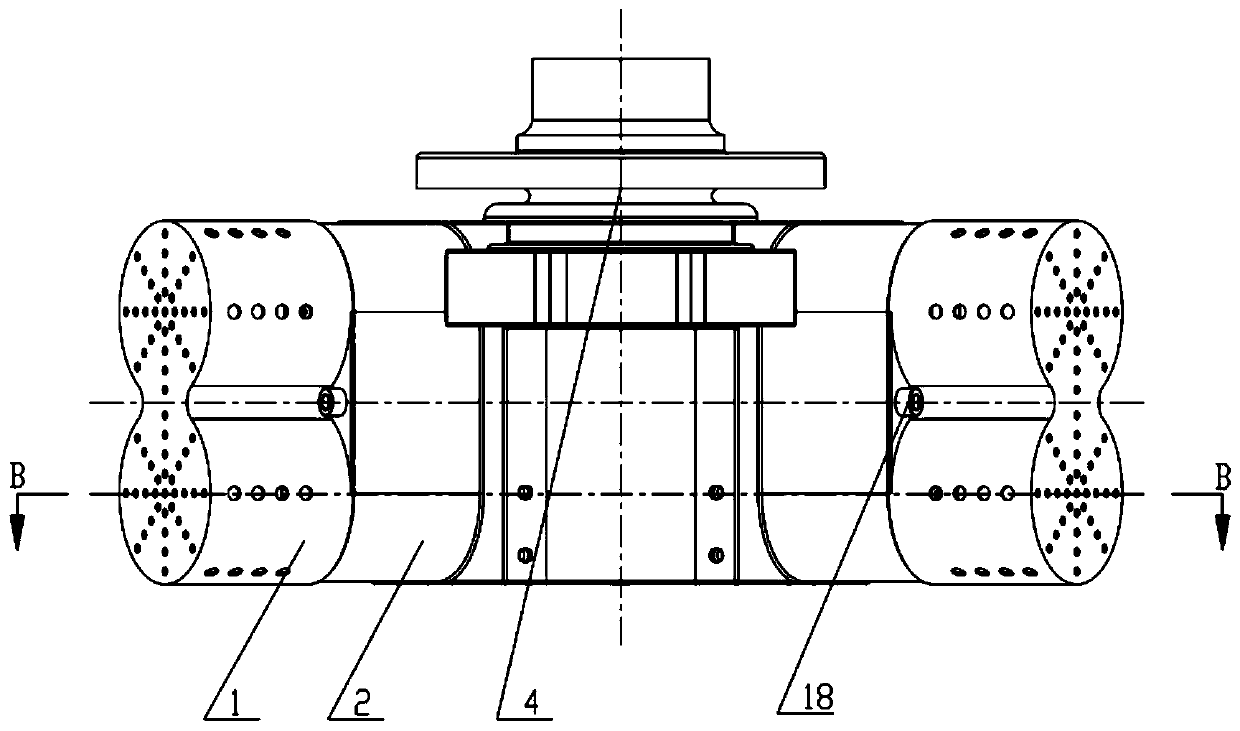

[0050] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-20 As shown, an electric vehicle ultrasonic suspension hub bearing includes a piezoelectric transducer 3, a bearing housing 2 and a cage assembly; there are 6 piezoelectric transducers 3, and each group of two is divided into three groups Installed on the three small boxes of the bearing box 2 in the circumferential direction; the cage assembly is installed in the circular through hole of the bearing box 2;

[0051] The piezoelectric transducer 3 includes a radiation head 8, a horn 9, an insulating sleeve 10, a rear cover 14 and a prestressed bolt 13;

[0052] The outer end surface of the radiation head 8 is a circular plane, and the inner end surface is a concave arc surface; the outer end of the radiation head 8 is connected with the horn 9; the outer end of the horn 9 has a flange; The above-mentioned prestressed bolts 13 pass through the rear cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com