Test piece surface principal stress testing device and method

A test method and technology of test device, which are applied in the direction of measuring device, force/torque/work measuring instrument, measuring force, etc., can solve the problems of complicated test and calculation process and inability to measure the whole field data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

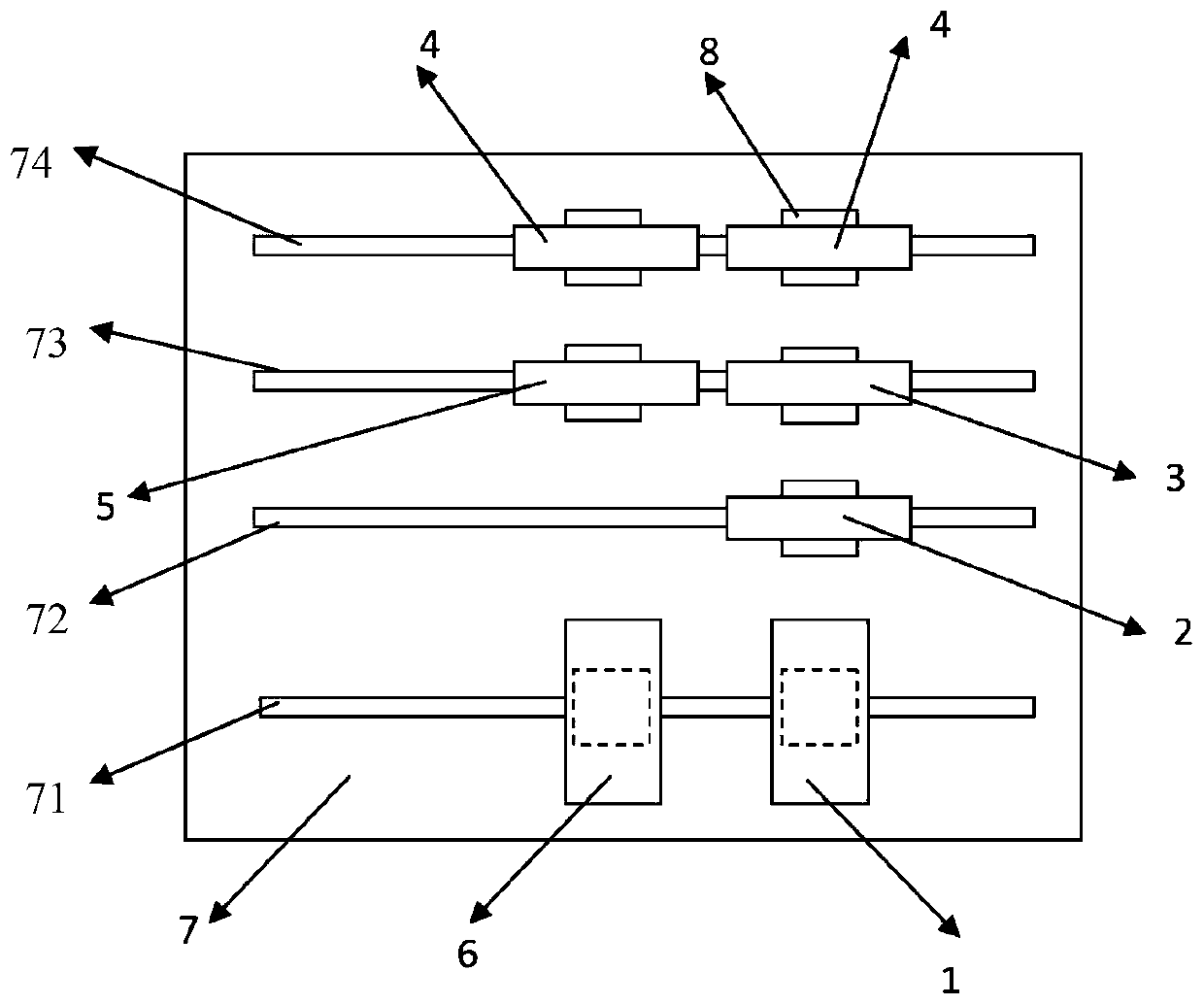

[0020] In order to better understand the purpose, structure and function of the present invention, a device and method for testing the surface principal stress of a test piece of the present invention will be described in further detail below in conjunction with the accompanying drawings.

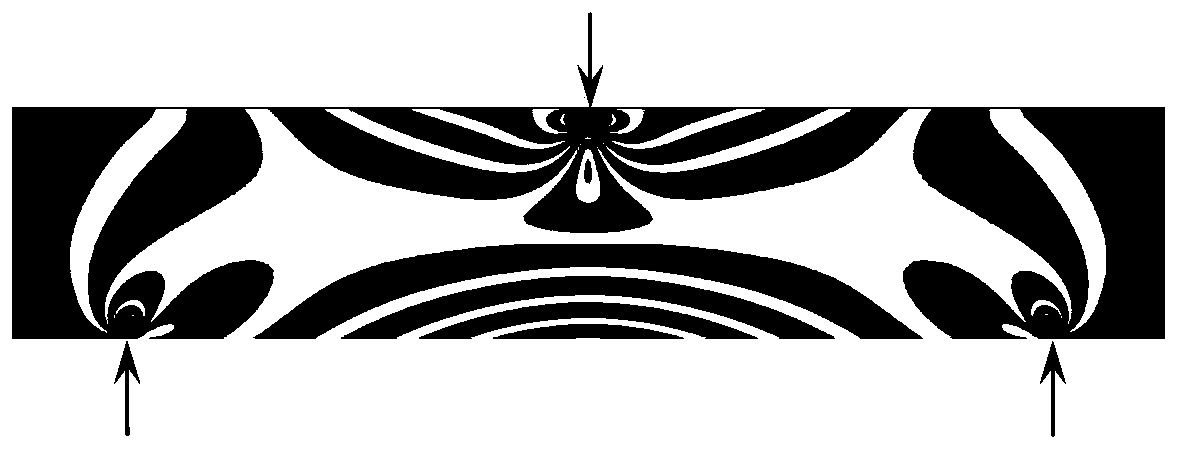

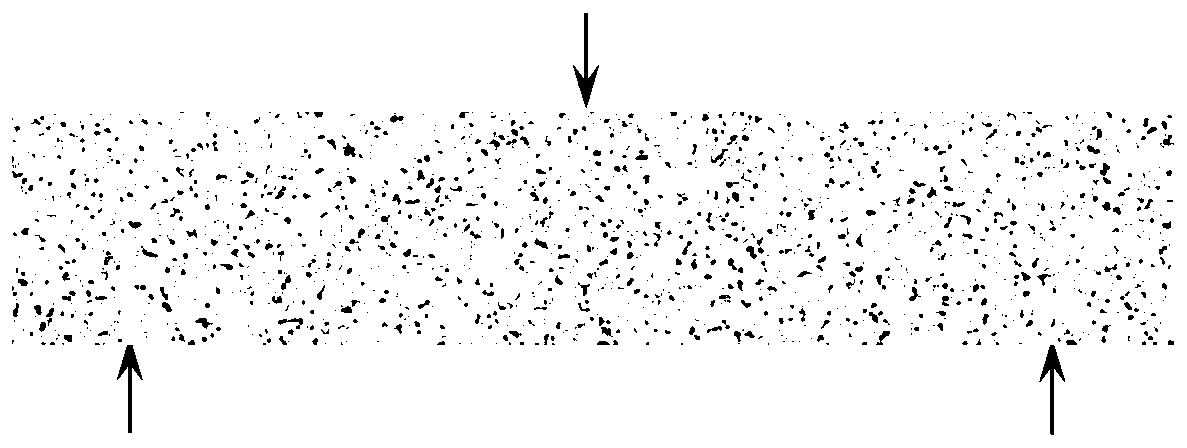

[0021] like Figure 1a to Figure 2b As shown, it is shown as a test piece surface principal stress testing device and method of the present invention, the principal stress test is carried out by the photoelastic patch method and the digital image correlation method, the testing device includes a photoelastic patch, a member to be tested and Assemblies, wherein the photoelastic patch in the present invention is pasted on the component to be tested, and the patch material is made by using epoxy resin with low viscosity and room temperature curing agent, and adding an appropriate amount of diluent. The photoelastic patch is pasted on the surface of the component to be tested with an adhesive. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com