Gluing method of entity sagnac interferometer

An interferometer and solid technology, applied in the direction of instrument, installation, optics, etc., can solve the problems of lower modulation degree of interferometer, complicated assembly and adjustment of gluing process, secondary repair of interferometer components, etc., to eliminate gluing stress and simple assembly and adjustment , Reduce the effect of bonding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

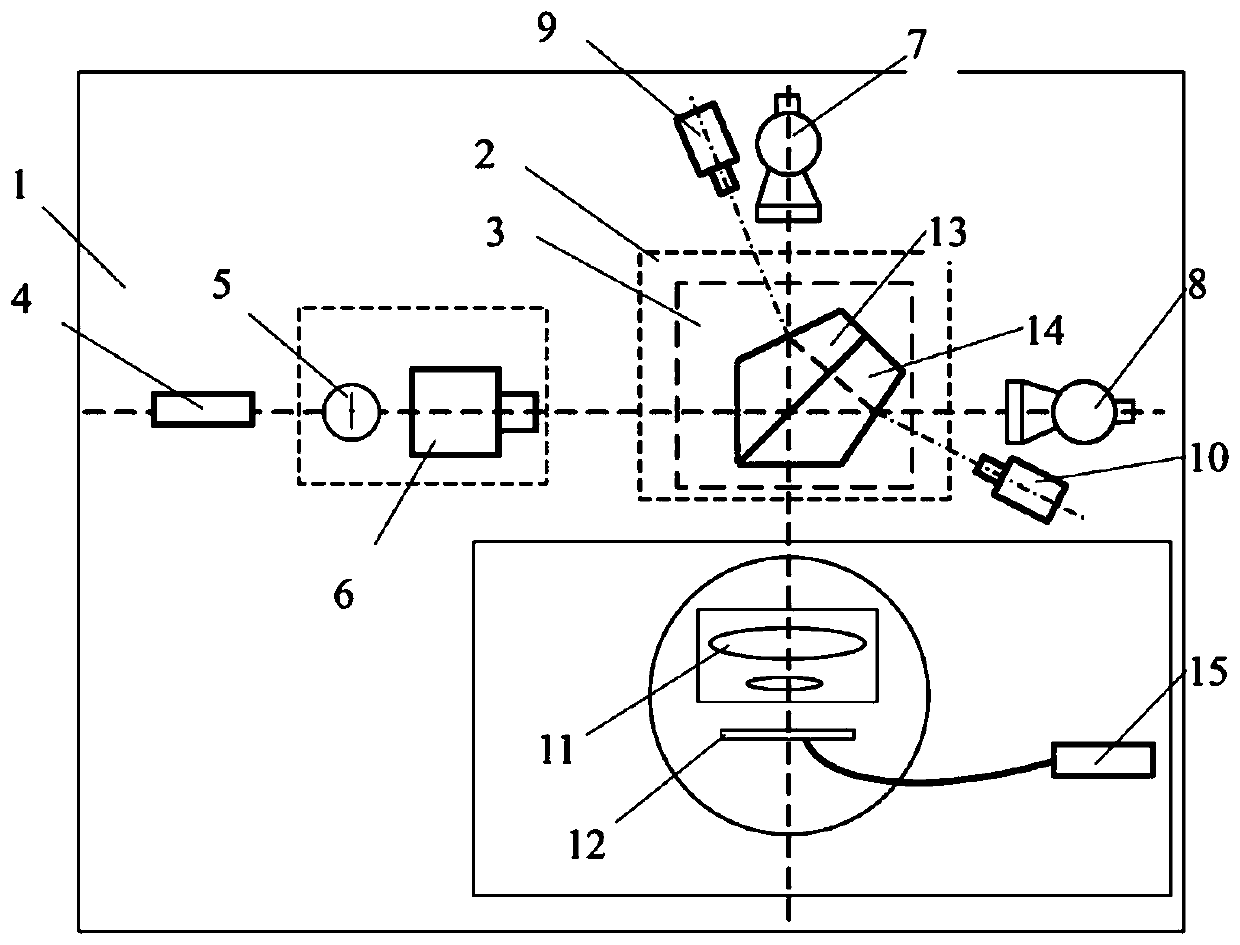

[0043] The gluing method of entity sagnac interferometer provided by the present invention comprises the following steps (with reference to Figure 2-3 ):

[0044] Step 1: Plating spectroscopic coating and anti-reflection coating

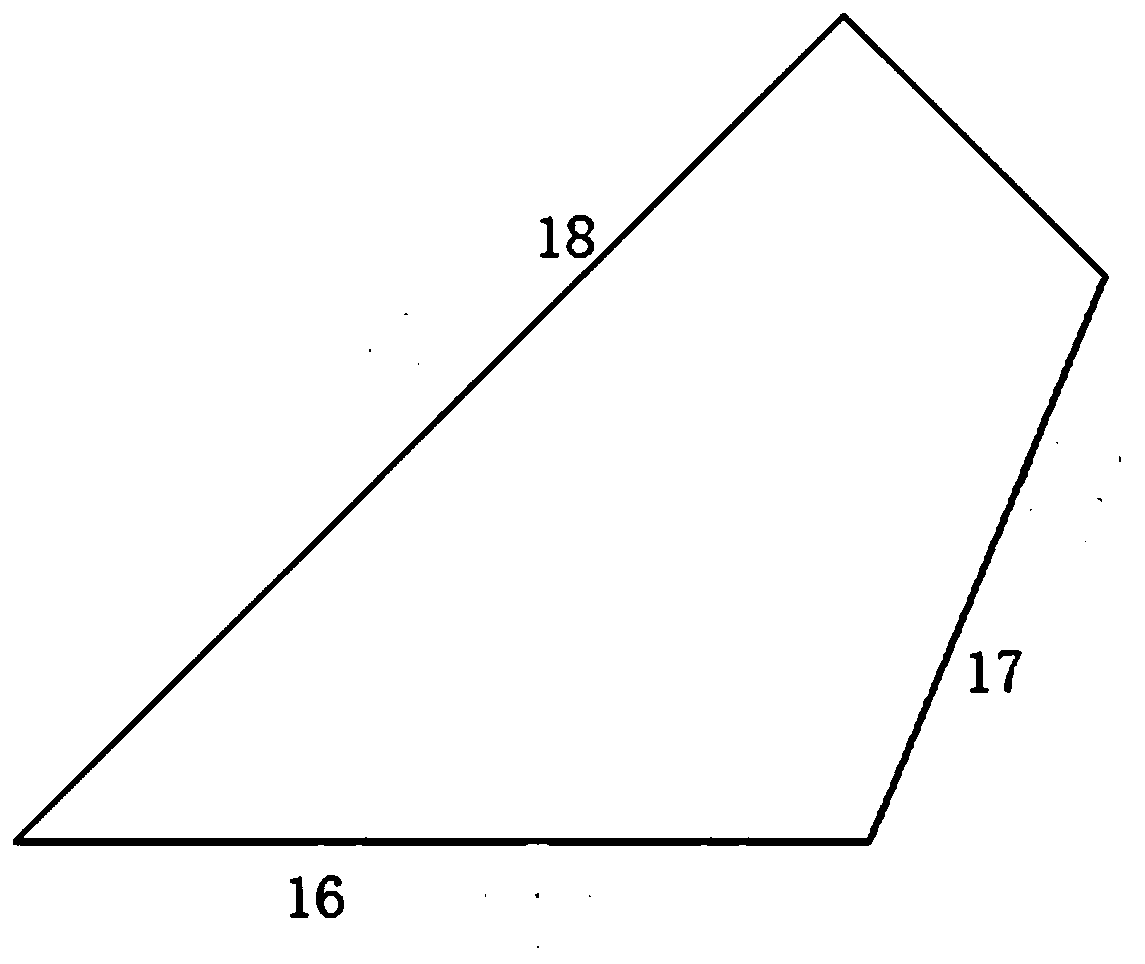

[0045] Before gluing, for the half pentagonal prism one 13 of constituting interferometer and half pentagonal prism two 14 on the transmissive surface 16 of anti-reflection coating, on reflective surface 17, do not plate reflective film earlier temporarily, on half pentagonal prism one 13 Or on the beam-splitting surface 18 of the half-pentagonal prism 2 14, a beam-splitting film is plated.

[0046] Step 2: Establish the main plane for installation and adjustment

[0047] 2.1) Use an electronic level to level the glued base 3, and the leveling accuracy depends on the accuracy required for the glued interferometer;

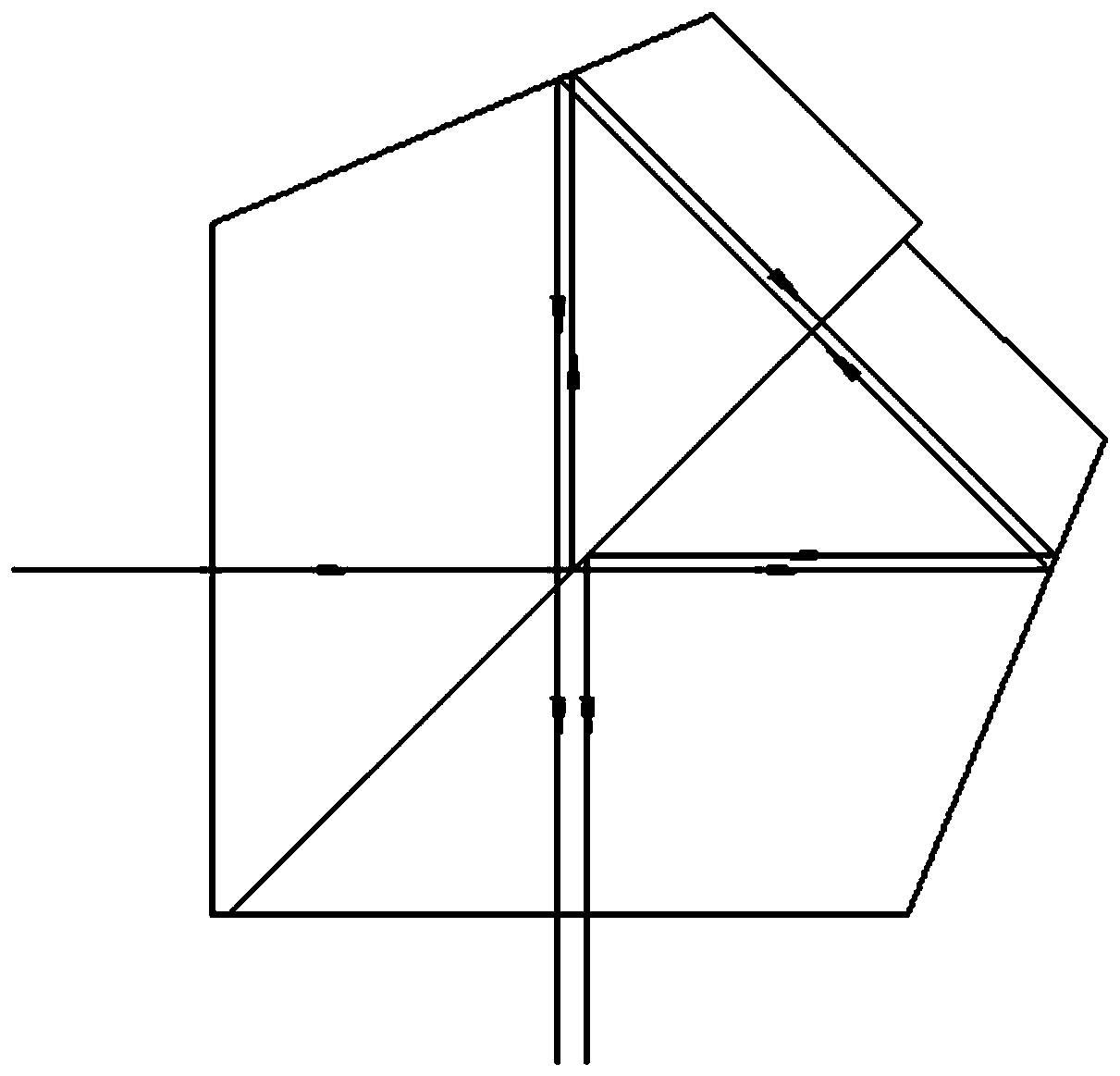

[0048] 2.2) Adjust the first theodolite 7 and the second theodolite 8 to the level, and calibrate the 90° included angle of the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com