Liquid crystal display screen shearing processing equipment

A liquid crystal display and processing equipment technology, applied in glass manufacturing equipment, manufacturing tools, glass cutting devices, etc., can solve the problems of glass plate displacement, glass plate not found in time, and beveled edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

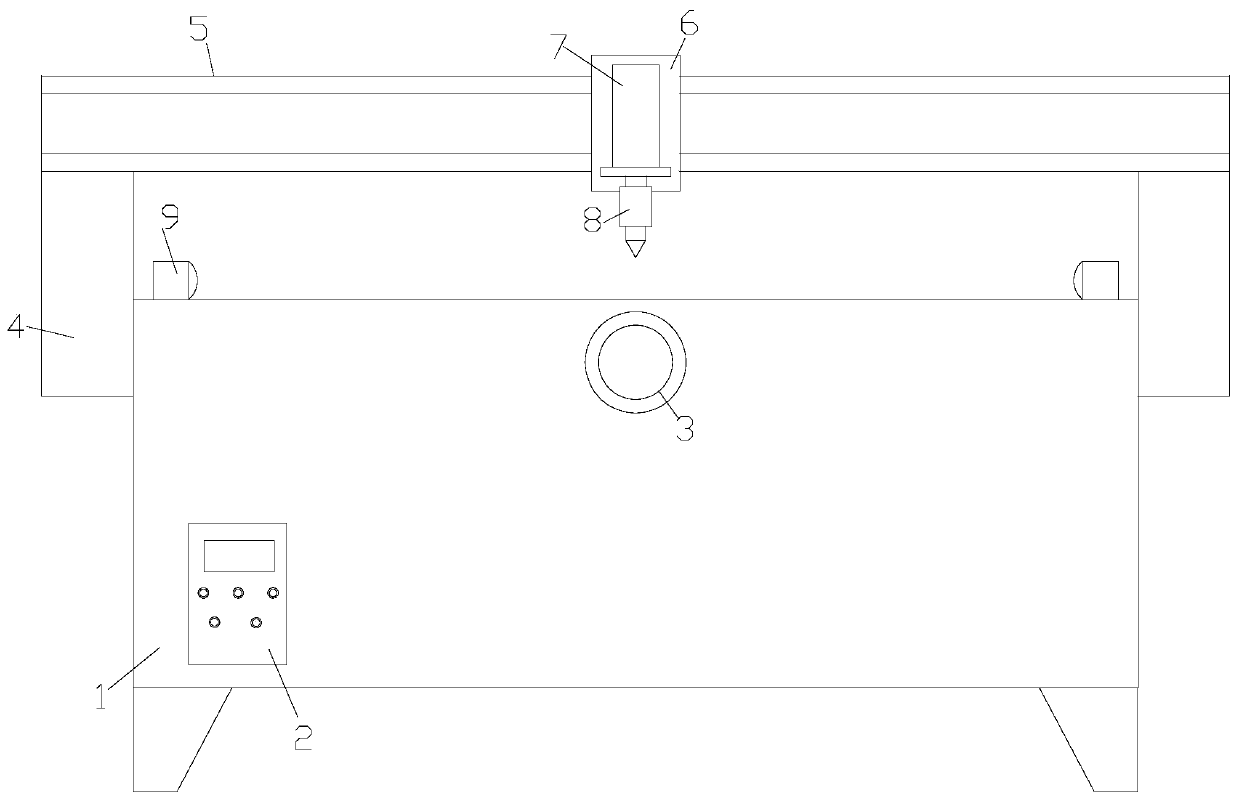

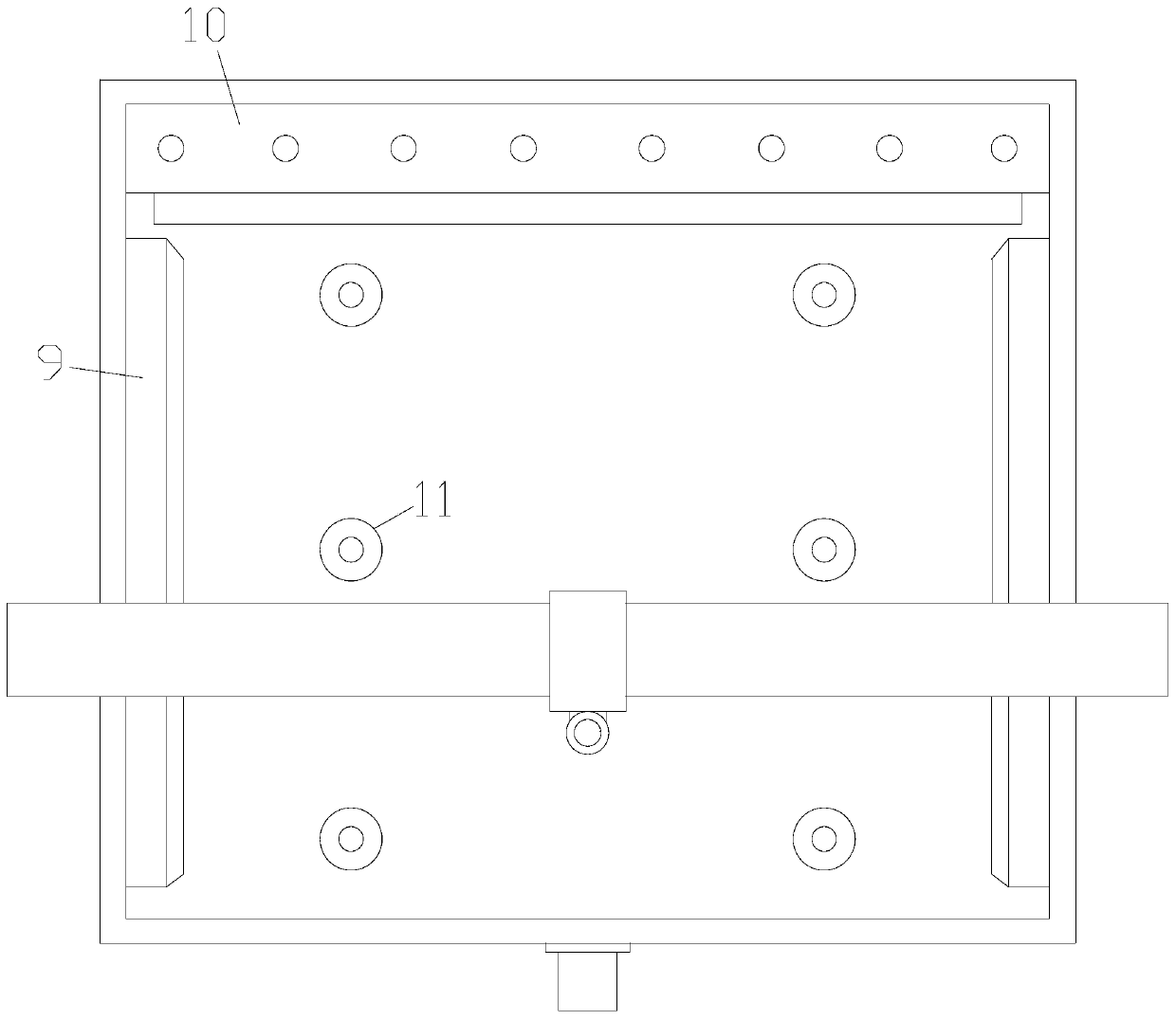

[0027] see Figure 1-Figure 5 , the present invention provides a liquid crystal display shearing processing equipment technical solution: its structure includes a workbench 1, a control box 2, a driving device 3, a front and rear moving frame 4, a lateral moving beam 5, a walking device 6, a lifting cylinder 7, a cutting 8, side clamp 9, the control box 2 is installed on the front of the workbench 1 through bolts, the front and rear moving frame 4 is installed on the left and right sides of the workbench 1 and the two are slidably matched, and the front and rear moving frame 4 is provided with a laterally moving beam 5 and a walking device 6 is provided on the laterally moving beam 5. The traveling device 6 is provided with a lifting cylinder 7 and a cutter 8. The left and right sides of the top end surface of the workbench 1 are Each activity is equipped with a side clamp 9, and the side clamp 9 is in transmission connection with the drive device 3 inside the workbench 1; Th...

Embodiment 2

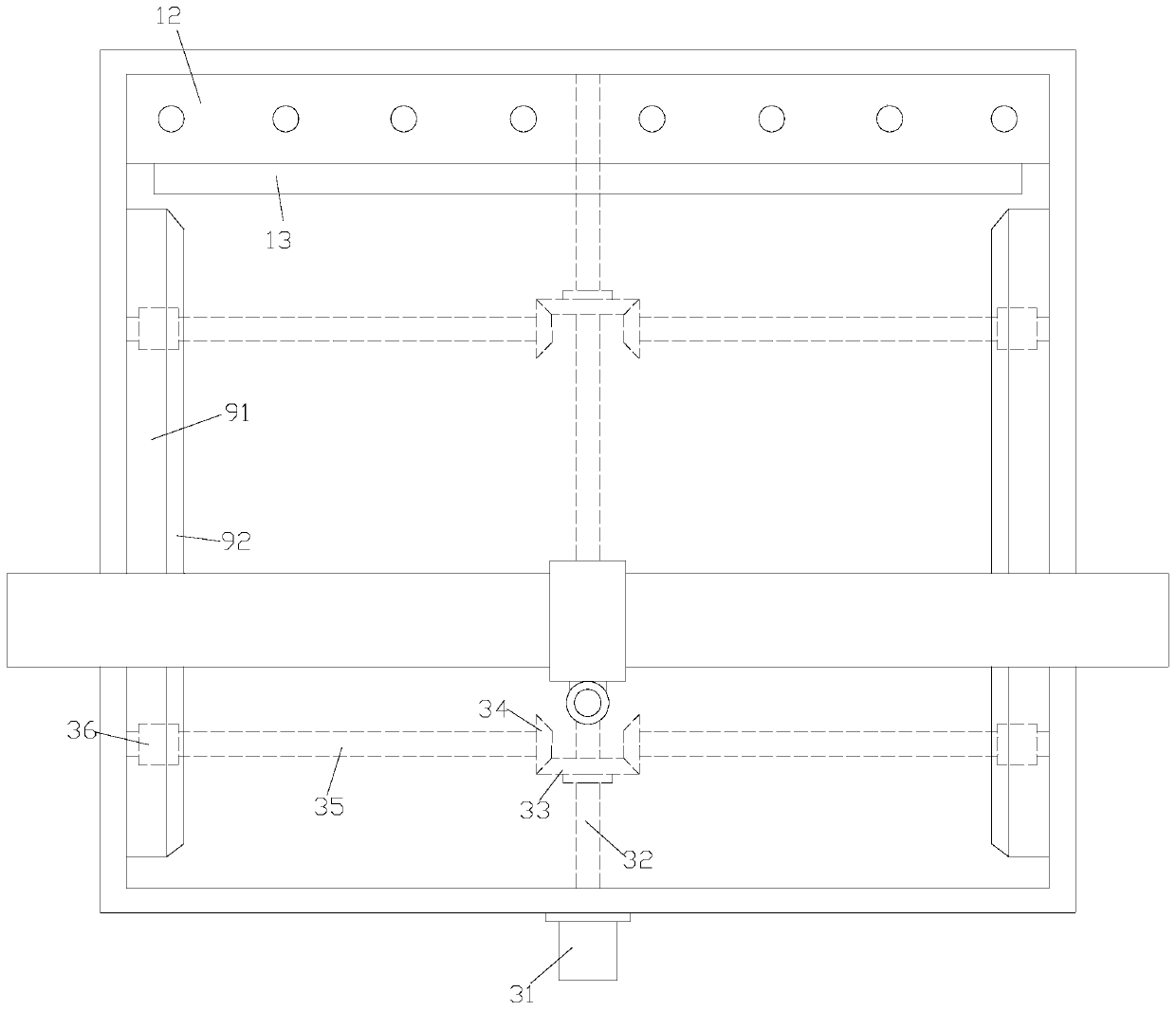

[0030] Such as image 3 As shown, on the basis of Embodiment 1, the driving device 3 is also composed of a motor 31, a rotating shaft 32, a main bevel gear 33, a driven gear 34, a screw mandrel 35 and a nut seat 36, and the motor 31 passes Bolts are installed on the end face of the front end of the workbench 1, one end of the rotating shaft 32 is connected with the motor 31, and the other end is connected with the inner wall of the rear end of the workbench 1. Screw mandrel 35, described screw mandrel 35 one ends are engaged with main bevel gear 33 on the rotating shaft 32 by driven gear 34, and the other end is fixed on the inner wall of workbench 1 left and right sides, and described screw mandrel 35 is provided with There is a nut seat 36 , and the side clamp 9 is composed of a splint 91 and a cushion 92 , the inner side of the splint 91 is provided with a cushion 92 , and the splint 91 is fixed above the nut seat 36 .

[0031] A driving device 3 is also installed inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com