Medical sterilization drying equipment

A technology of drying equipment and sterilizing tank, which is applied in the field of medical sterilization and drying equipment, can solve the problems of easy damage of utensils, time-consuming and labor-intensive, etc., and achieve the effects of preventing skewing, good sterilization effect, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

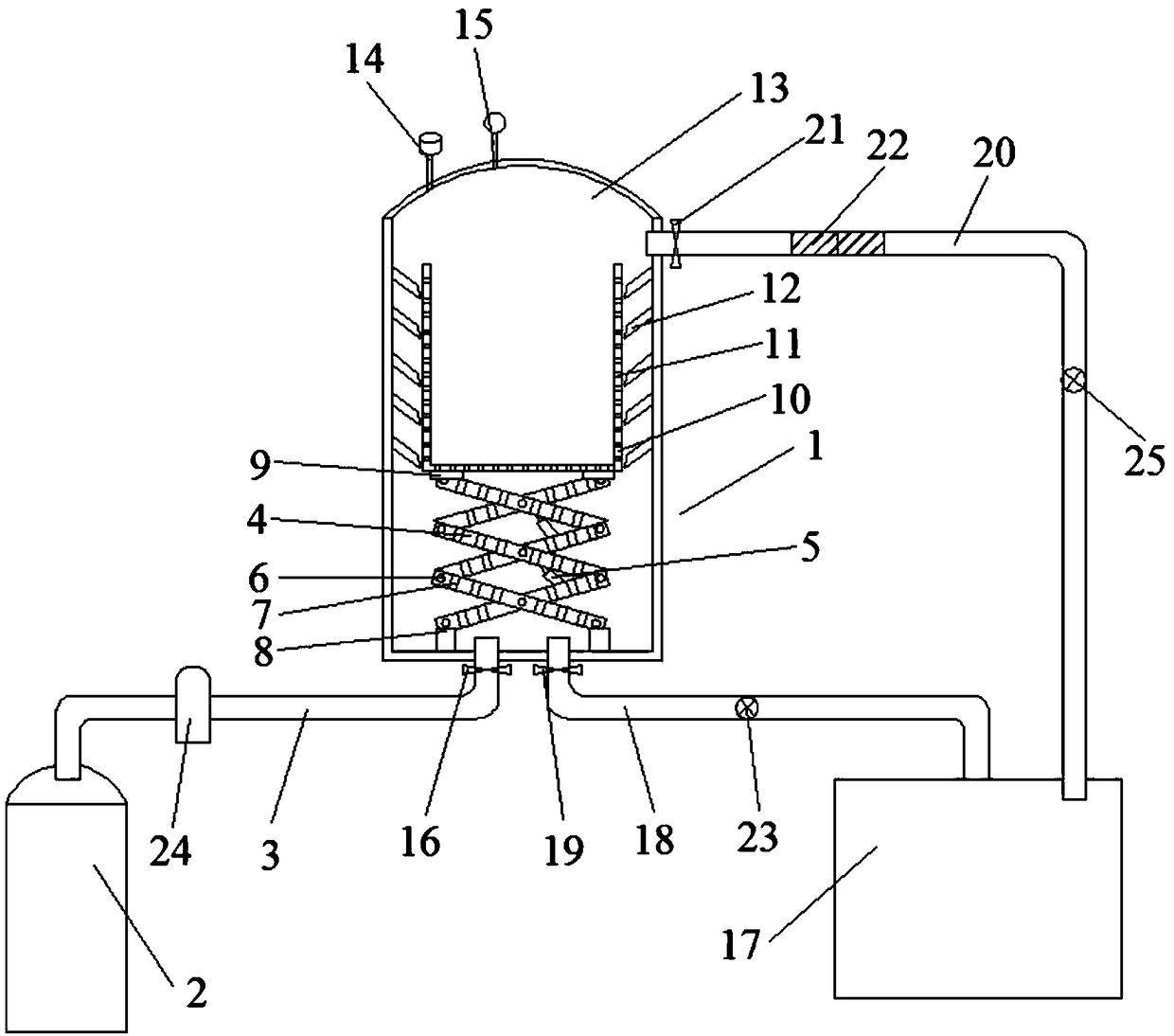

[0020] Such as figure 1 As shown, a medical sterilization and drying equipment includes a sterilization mechanism and a drying mechanism. The sterilization mechanism includes a sterilization tank 1 and a steam supply mechanism connected to the bottom of the sterilization tank 1. The drying The mechanism includes a heating air duct 18 communicating with the heating air box 17, the heating air duct 18 communicates with the bottom of the sterilization tank 1, and the heating air duct 18 is provided with a second A valve 19, a support mechanism is arranged in the sterilization tank 1, a sterilization basket 10 is arranged on the upper part of the support mechanism, and a plurality of third through holes 11 are arranged on the casing of the sterilization basket 10. The top of the sterilization tank 1 is provided with a detachable tank cover 13, and the tank cover 13 is provided with a safety valve 14 and an exhaust valve 15.

[0021] Working principle: open the tank cover 13, put ...

Embodiment 2

[0023] Based on Example 1, such as figure 1 As shown, the hot air circulation pipe 20 is also communicated with the hot air circulation pipe 17, and the hot air circulation pipe 20 communicates with the upper side of the sterilization tank 1, and the hot air circulation pipe 20 is provided with a third Valve 21 and second fan 25.

[0024] After drying for a period of time, open the third valve 21, and under the action of the second fan 25, the humid gas in the sterilization tank 1 is drawn out, and enters the heating air box 17 through the hot air circulation pipe 20 to be heated and reused to circulate the hot air Utilize, save energy.

Embodiment 3

[0026] Based on Example 1, such as figure 1 As shown, the hot air circulation pipe 20 is provided with at least one water-absorbing layer 22 .

[0027] The water-absorbing layer 22 absorbs the moisture in the humid gas, and the dried gas directly enters the heating air box 17 to be heated and utilized again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com