A stainless steel thin plate batch cutting equipment

A cutting equipment, stainless steel technology, applied in shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problems of low efficiency and low cutting accuracy, and achieve the purpose of avoiding scratches, ensuring cutting accuracy and reducing friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

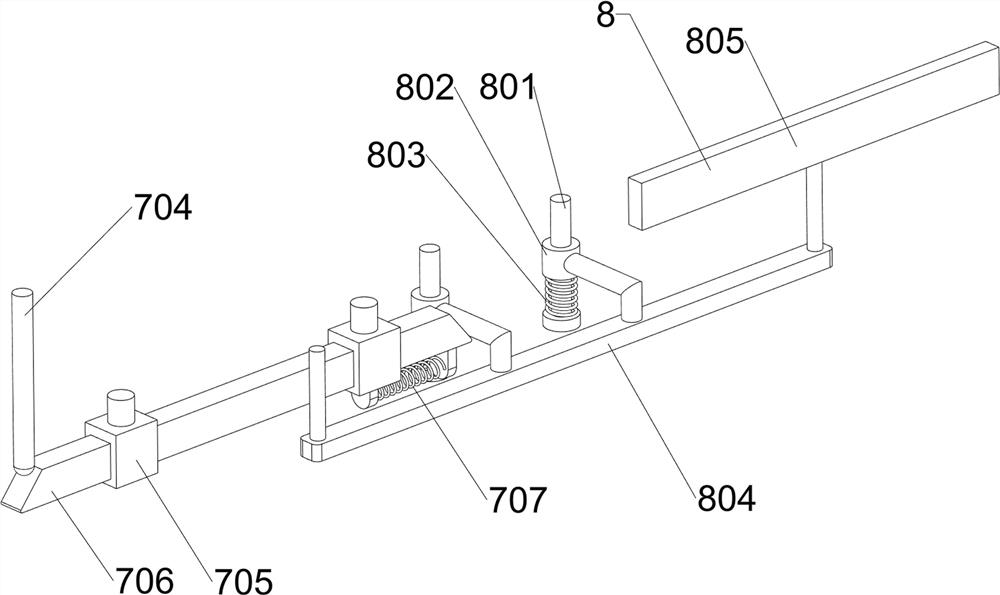

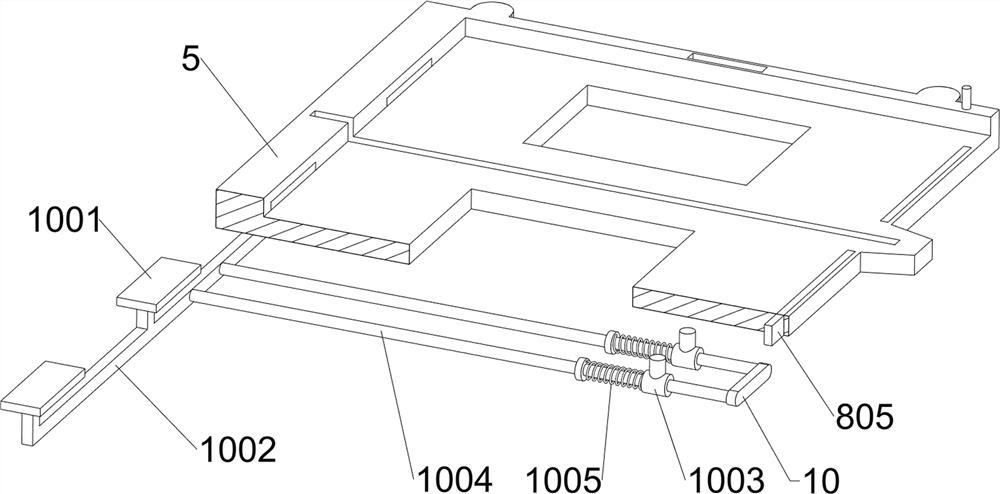

[0030] A stainless steel thin plate batch cutting equipment, such as Figure 1-6 As shown, it includes a base plate 1, a frame 2, a cylinder 3, a drive assembly 4, an installation frame 5, a cutting assembly 6, a transmission assembly 7 and a limit assembly 8, and the top of the base plate 1 is connected with the frame 2 and the installation frame 5. The frame 2 is located at the rear side of the installation frame 5, the cylinder 3 is installed on the top of the frame 2, the driving assembly 4 is installed on the frame 2, the cutting assembly 6 and the transmission assembly 7 are installed on the installation frame 5, and the limiter is installed on the bottom of the installation frame 5. Component 8.

[0031] When it is necessary to cut the stainless steel sheet, people put the stainless steel sheet in the installation frame 5, and then control the extension of the cylinder 3, and the cylinder 3 drives the drive assembly 4 to work, and the drive assembly 4 drives the limit a...

Embodiment 2

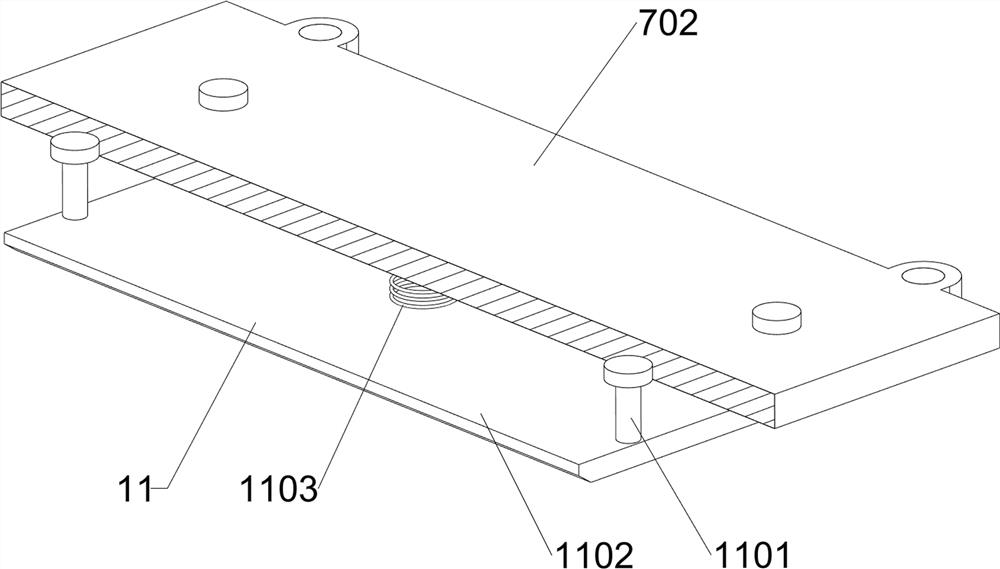

[0041] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 , Figure 7 and Figure 8 As shown, an auxiliary assembly 9 is also included. The auxiliary assembly 9 includes a second support frame 901, a mounting plate 902, a guide roller 903 and a fifth spring 904. The bottom of the installation frame 5 is slidingly provided with a second support frame 901, and the second Four mounting plates 902 are connected to the top of the support frame 901, and a plurality of guide rollers 903 are installed on the top of each mounting plate 902. The guide rollers 903 pass through the mounting frame 5, and the second mounting plate 901 is connected between the mounting frame 5 and the second support frame 901. Five springs 904.

[0042] People put the stainless steel sheet into the installation frame 5, the stainless steel sheet rolls on the guide roller 903, reduces the frictional force, plays a protective role to the stainless steel sheet, avoids the stainless steel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com