Mid-span damping type stepless self-locking pushing device for flat-turning opening bridge

A push-up device and shock-absorbing technology, applied in springs/shock absorbers, bridges, suspension bridges, etc., can solve problems such as inability to achieve stepless connection, wear, and affecting the normal operation of bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] All features disclosed in this specification, or steps in all methods or processes disclosed, can be combined in any way, except for mutually exclusive features and steps.

[0022] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

[0023] The structure and principle of the mid-span stepless shock-absorbing self-locking jacking device of the horizontal swing open bridge of the present invention will be described in detail below.

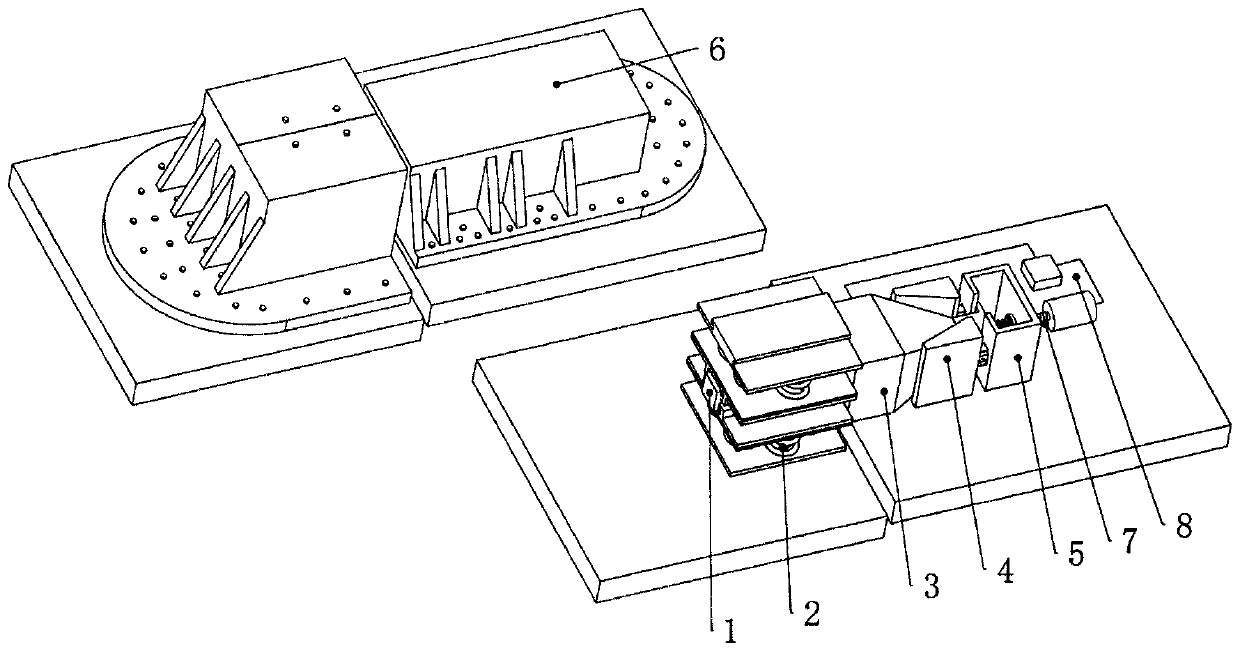

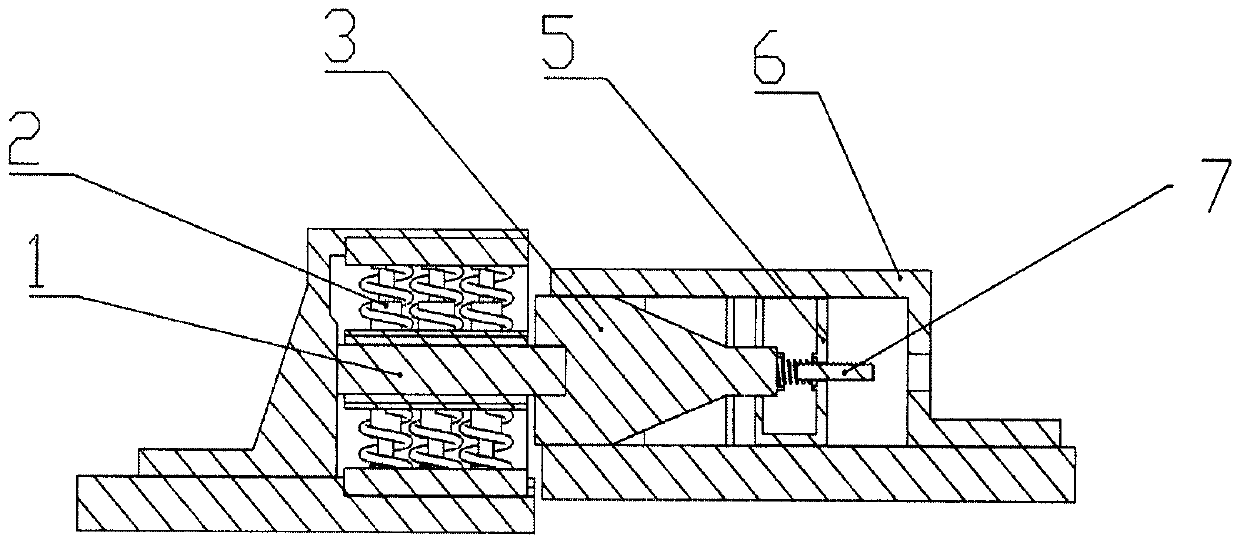

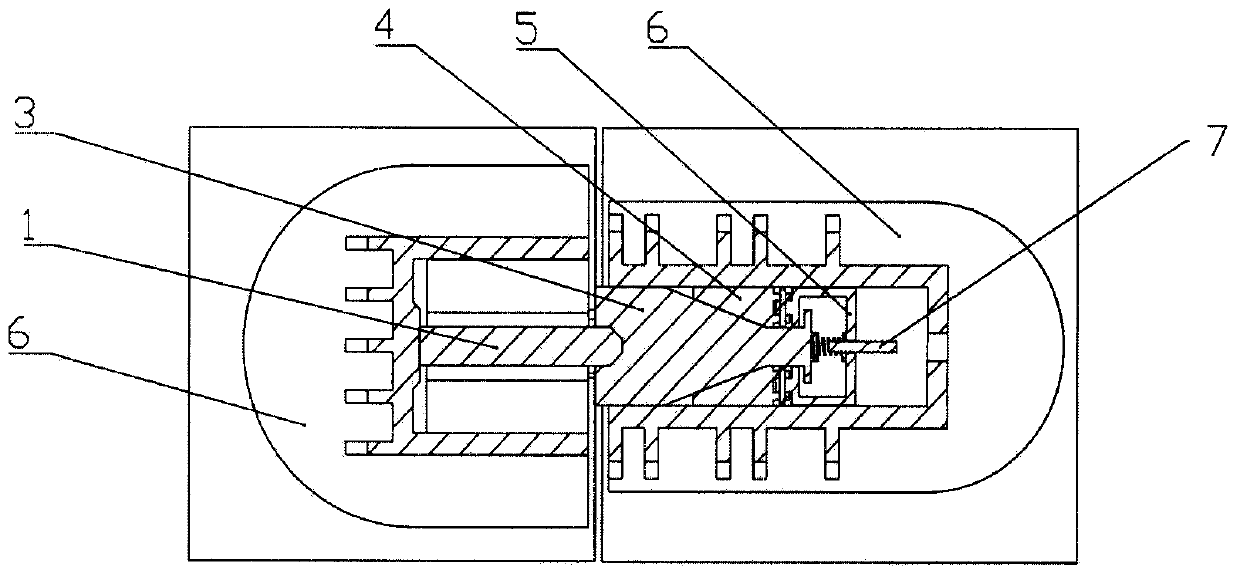

[0024] figure 1 A schematic diagram of the overall structure of the mid-span shock-absorbing type stepless self-locking jacking device of the horizontal swing opening bridge according to the present invention is shown. The mid-span shock-absorbing stepless self-locking thrusting device of the horizontal sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com