Fireproof heat preservation curtain wall and manufacturing method thereof

A technology for fire prevention and heat preservation and manufacturing method, which is applied in the directions of heat preservation, fire prevention, and wall, can solve the technical problems of cold and hot bridges, the inability to use building curtain walls, and the easy generation of toxic substances, so as to reduce the overall cost, and the overall quality is easy to ensure. The effect of improving the thermal insulation effect and the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

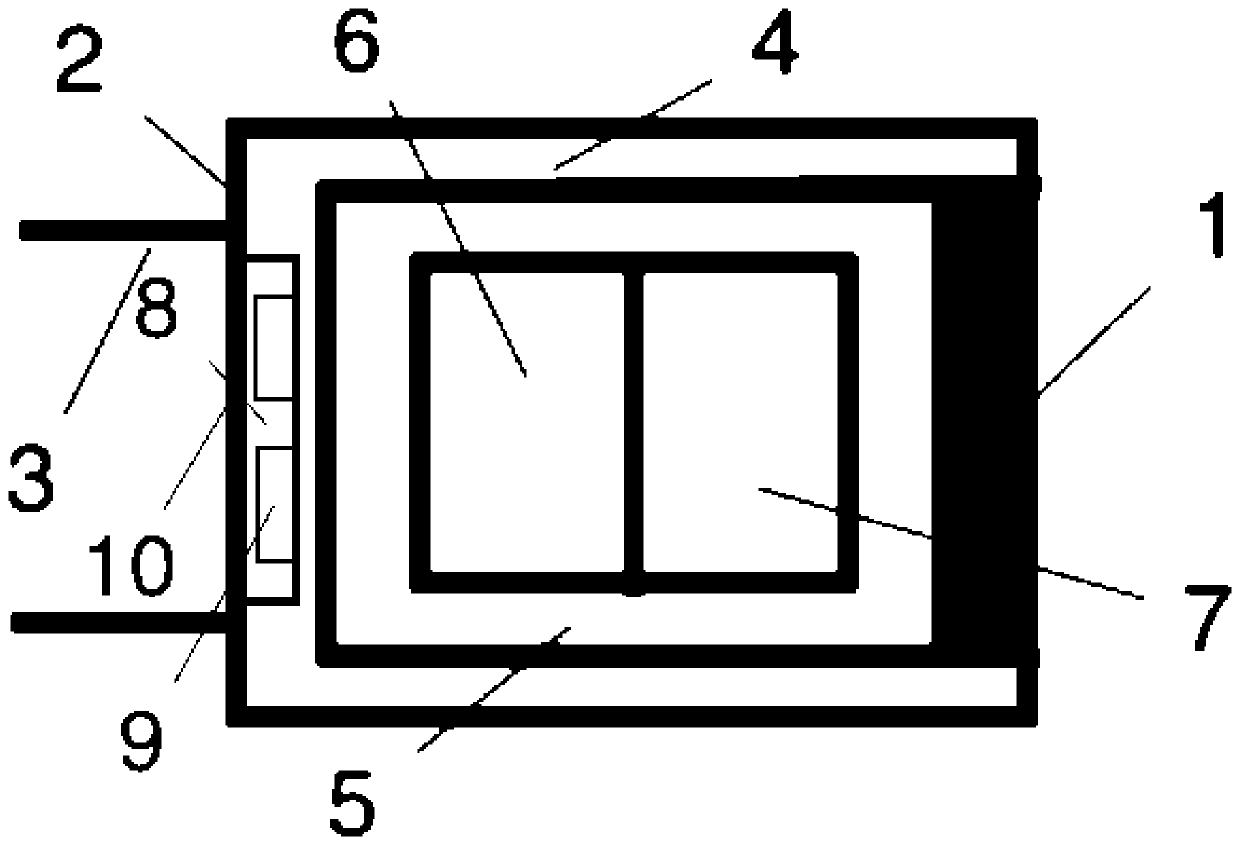

[0034]A fireproof and thermal insulation curtain wall, comprising a curtain wall layer 1, a curtain wall core block 2 and a connector 3; the curtain wall layer 1 is fixed in the outer fireproof layer 4 of the curtain wall core block 2, and the curtain wall core block 2 passes through the The connector 3 is fixed to the wall;

[0035] The curtain wall core block 2 includes an outer fireproof layer 4 and an inner fireproof layer 5 from the outside to the inside. The inner fireproof layer 5 is in the form of a closed square frame, and a first thermal insulation layer 6 and a second thermal insulation layer 6 and a second thermal insulation layer are vertically arranged side by side in parallel. Layer 7; grooves 8 are arranged on the outer surface of the outer fireproof layer 4 close to the wall, a plurality of automatic sprinklers 9 are arranged in the grooves 8, and a layer of protective film 10 is covered on the grooves 8, The protective film 10 is a low melting point film;

...

Embodiment 2

[0054] A fireproof and thermal insulation curtain wall, comprising a curtain wall layer 1, a curtain wall core block 2 and a connector 3; the curtain wall layer 1 is fixed in the outer fireproof layer 4 of the curtain wall core block 2, and the curtain wall core block 2 passes through the The connector 3 is fixed to the wall;

[0055] The curtain wall core block 2 includes an outer fireproof layer 4 and an inner fireproof layer 5 from the outside to the inside. The inner fireproof layer 5 is in the form of a closed square frame, and a first thermal insulation layer 6 and a second thermal insulation layer 6 and a second thermal insulation layer are vertically arranged side by side in parallel. Layer 7; grooves 8 are arranged on the outer surface of the outer fireproof layer 4 close to the wall, a plurality of automatic sprinklers 9 are arranged in the grooves 8, and a layer of protective film 10 is covered on the grooves 8, The protective film 10 is a low melting point film;

...

Embodiment 3

[0077] A fireproof and thermal insulation curtain wall, comprising a curtain wall layer 1, a curtain wall core block 2 and a connector 3; the curtain wall layer 1 is fixed in the outer fireproof layer 4 of the curtain wall core block 2, and the curtain wall core block 2 passes through the The connector 3 is fixed to the wall;

[0078] The curtain wall core block 2 includes an outer fireproof layer 4 and an inner fireproof layer 5 from the outside to the inside. The inner fireproof layer 5 is in the form of a closed square frame, and a first thermal insulation layer 6 and a second thermal insulation layer 6 and a second thermal insulation layer are vertically arranged side by side in parallel. Layer 7; grooves 8 are arranged on the outer surface of the outer fireproof layer 4 close to the wall, a plurality of automatic sprinklers 9 are arranged in the grooves 8, and a layer of protective film 10 is covered on the grooves 8, The protective film 10 is a low melting point film;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com