Novel shock resisting device and working method thereof

An impact-resistant and new type of technology, applied in buffers, transportation and packaging, shock absorbers, etc., can solve the problems of collision damage, no car anti-collision buffer device is found, to prevent mine cars from overspeeding and increase adaptability , the effect of preventing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

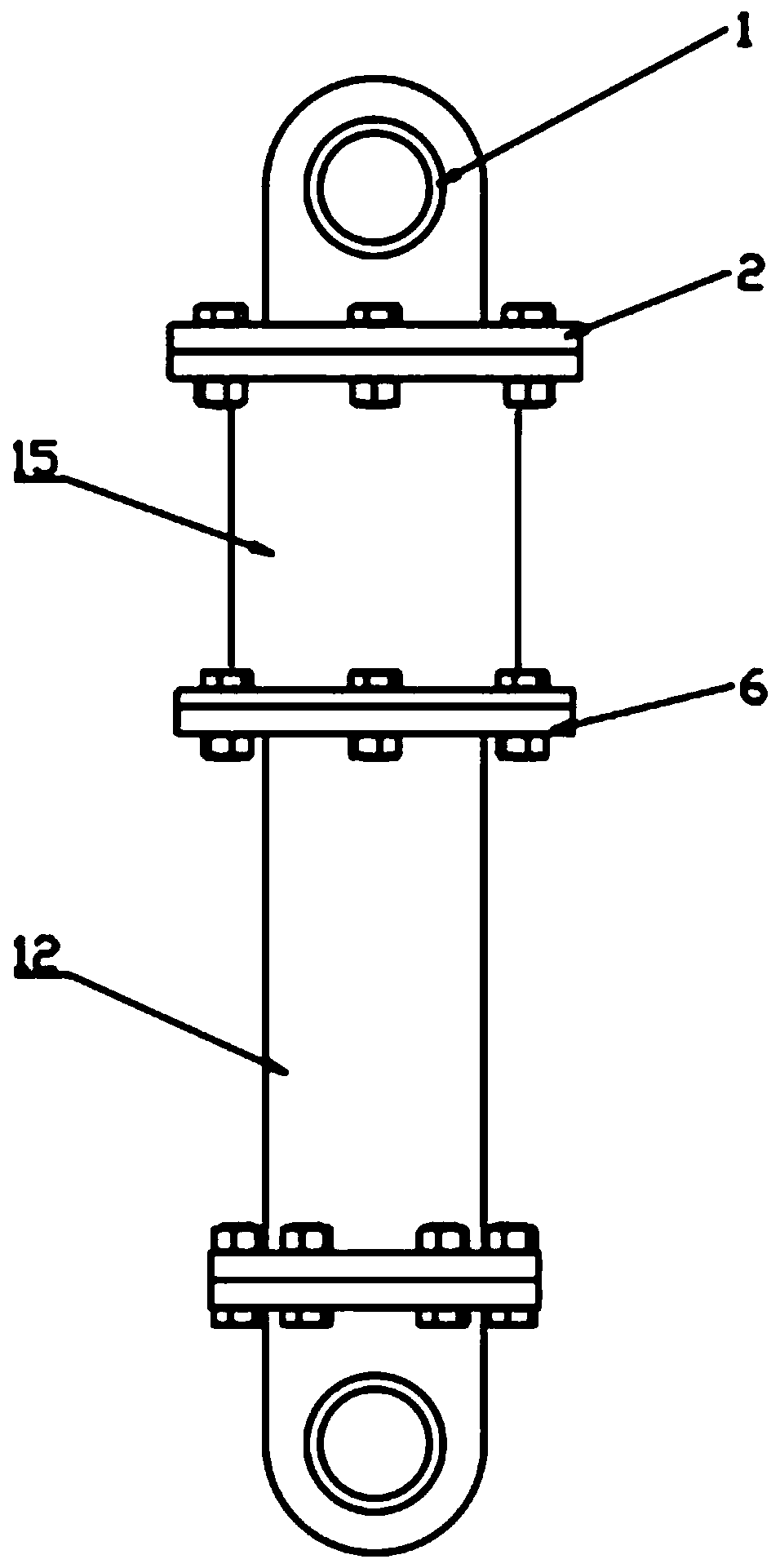

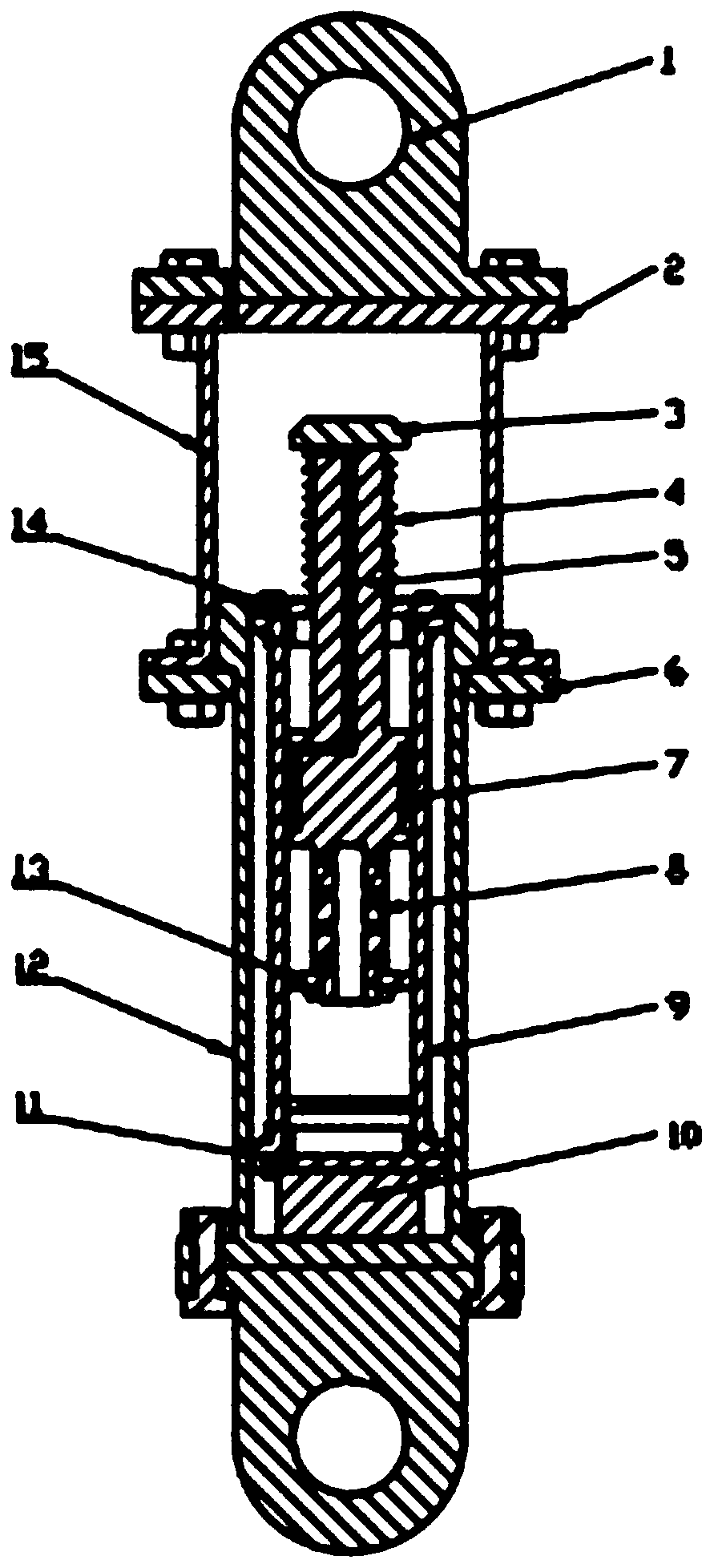

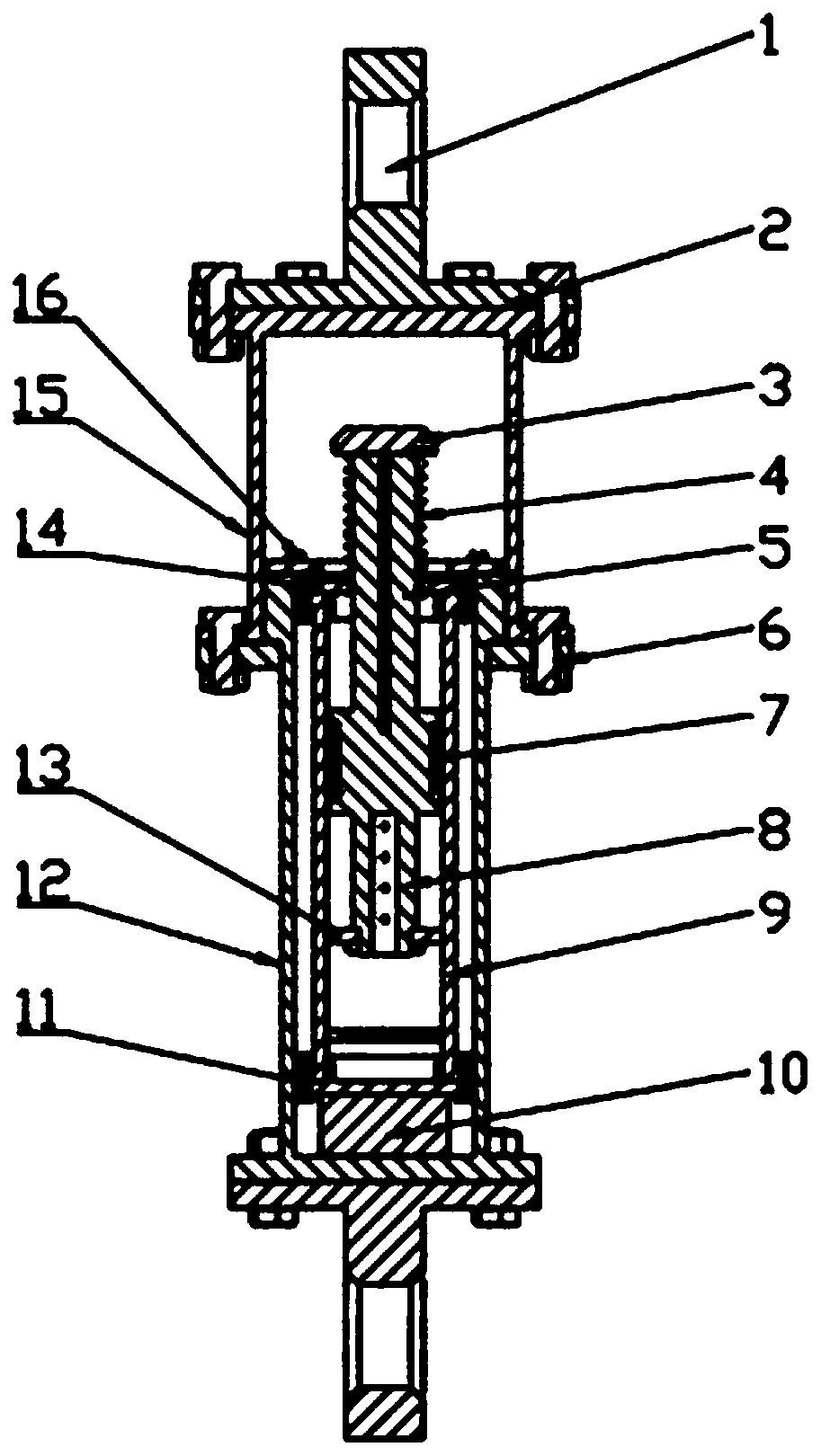

[0045] Such as Figure 1-Figure 4 As shown, this embodiment provides a new type of anti-shock device, including a first connector connected in sequence, an upper outer cylinder 15, a lower outer cylinder 12 and a second connector, the first connector is fixedly connected to the upper outer cylinder 15, The second connector is fixedly connected to the lower outer cylinder 12, and the top of the lower outer cylinder 12 is inserted into the upper outer cylinder 15 to be flexibly connected to the upper outer cylinder 15;

[0046]The lower outer cylinder 12 is provided with an aluminum honeycomb 10 and a magneto-rheological buffer outer cylinder 9. The upper and lower ends of the magnetorheological buffer outer cylinder 9 are respectively encapsulated by an upper end cover 14 and a lower end cover 11, and the aluminum honeycomb 10 is arranged on the lower end cover. 11 At the bottom, a piston rod 5 is arranged inside the outer cylinder 9 of the magneto-rheological buffer. The top e...

Embodiment 2

[0056] A working method in which a new anti-shock device is applied between two compartments of a mine car. The novel anti-shock device described in Example 1 is connected between the two compartments of a mine car, that is, the first connector, the second The two connectors are connected to the adjacent two compartments, and then the anti-shock device and the speed sensor on the mine car are connected to the two-dimensional fuzzy controller to form a buffer control system. The working method of the new anti-shock device includes the following step:

[0057] A minecart up stage

[0058] When the speed of the front vehicle is greater than the speed of the rear vehicle, the upper outer cylinder 15 pulls the lower outer cylinder 12 upward, the piston rod 5 is in the extended state, the magnetorheological buffer outer cylinder 9 is filled with magnetorheological fluid, and the electromagnetic coil 7 is energized at this time state, but the bumper 3 is not impacted, and the new an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com