Phase change type high-pressure electrode boiler

A high-voltage electrode and boiler technology, which is applied in the direction of electrode boilers, steam boilers, steam boiler accessories, etc., can solve the problems of high voltage of the equipment shell, increase boiler failure points, and occupy a large area, so as to achieve reliable operation, improve reliability and The effect of maintainability and flexible load adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

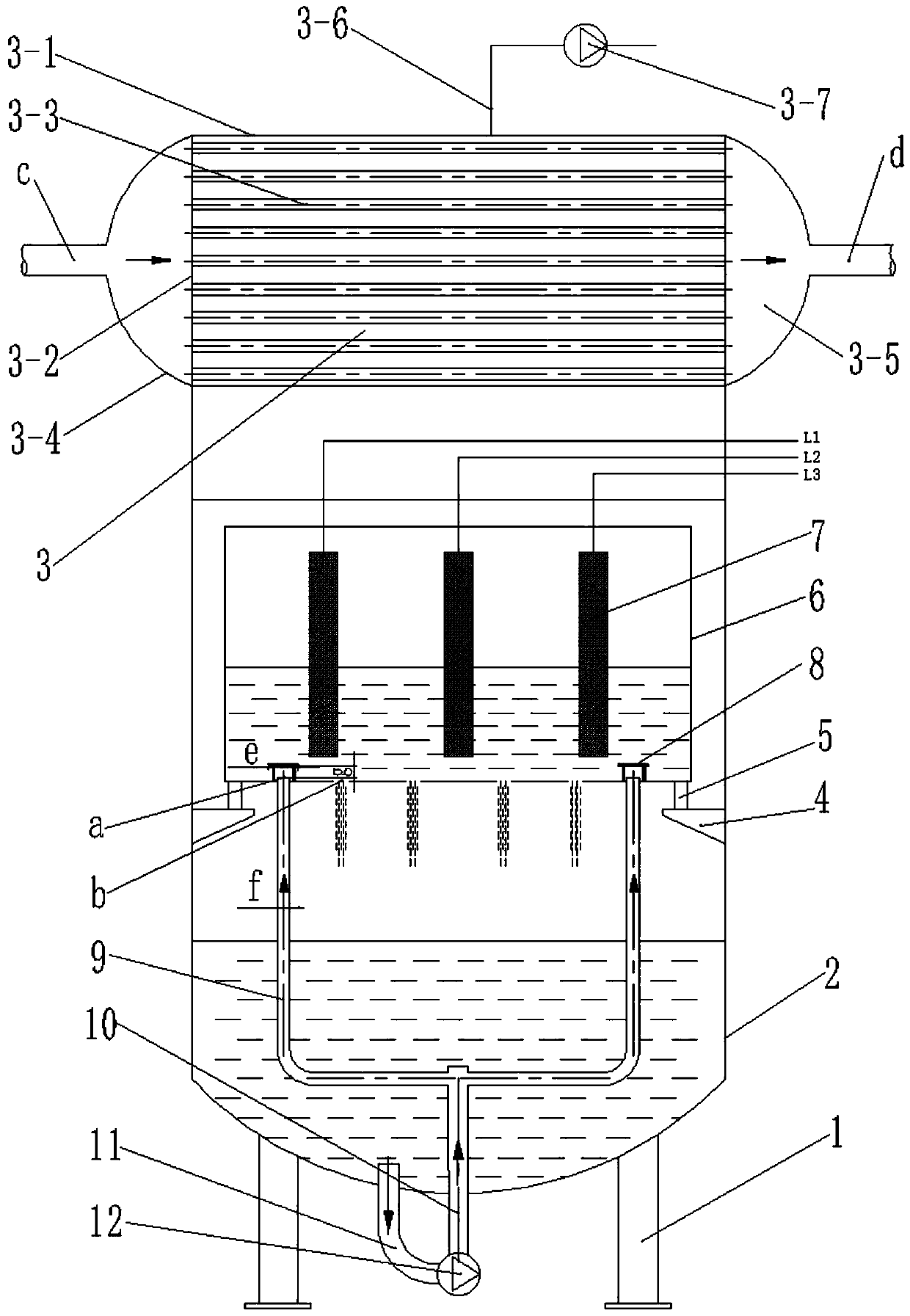

[0024] exist figure 1 Among them, a phase-change high-voltage electrode boiler of the present invention includes a leg 1, a pot shell 2 mounted on the leg, a phase-change heat exchanger 3 mounted on the top, and several support legs mounted on the inner wall of the pot shell. Seat 4, an insulating heat-resistant seat 5 installed on the support, the bottom is provided with a water distribution hole a, a water drop hole b and an inner cylinder 6 installed on the insulating seat, connected with the external circuit, located in the cavity of the inner cylinder and A number of high-voltage electrodes 7 suspended on the inner cylinder through insulators, a water distribution plate 8 installed above the water inlet hole at the bottom of the inner cylinder, and a U-shaped water distribution pipe connected to the water inlet hole at the bottom of the inner cylinder and installed on the bottom of the inner cylinder 9. The water delivery pipe 10 connected with the bottom of the U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com