Heating network draining system for circulating fluidized bed cogeneration unit under cylinder cutting working condition

A technology of combined heat and power unit and circulating fluidized bed, which is applied in hot water central heating system, heating system, household heating, etc., can solve problems such as waste of heat energy, improve operation reliability, reduce temperature, and increase operation The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

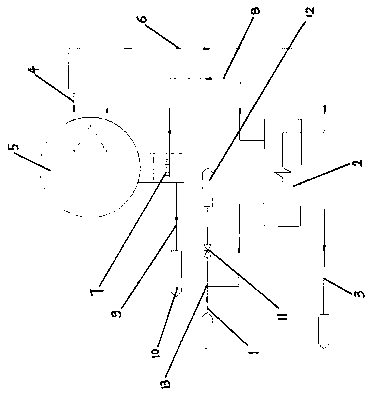

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

[0011] A heat network drainage system of a circulating fluidized bed cogeneration unit under the condition of cutting cylinders, comprising a main engine exhaust device 10 of a circulating fluidized bed cogeneration unit, a condensate pipeline 12 of a main engine of a circulating fluidized bed cogeneration unit, Heat network condenser 5, heat supply first station heating network drainage pipeline 1, heating first station return water pipeline 3, heating network circulating water return pipeline 4 and drain cooling heat exchanger 2, in the heat network condenser 5 is provided with a flash spray device 7 and a heat network condenser output water pipeline 9, and the other end of the heat network condenser output water pipeline 9 communicates with the exhaust device 10 of the main engine of the circulating fluidized bed cogeneration unit. The heat exchange and cooling input water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com