Industrial water replenishing and deoxidizing system and method for low-pressure cylinder cutting unit

A technology of replenishing water system and low-pressure cylinder, which is applied in the direction of separation method, supplementary water supply, chemical instruments and methods, etc., which can solve the problems of high superheat degree of middle exhaust steam, increase of heat load of condenser, influence of heat recovery effect, etc., and achieve elimination Supercooling, increasing the inlet water temperature, and avoiding the effect of poor oxygen removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

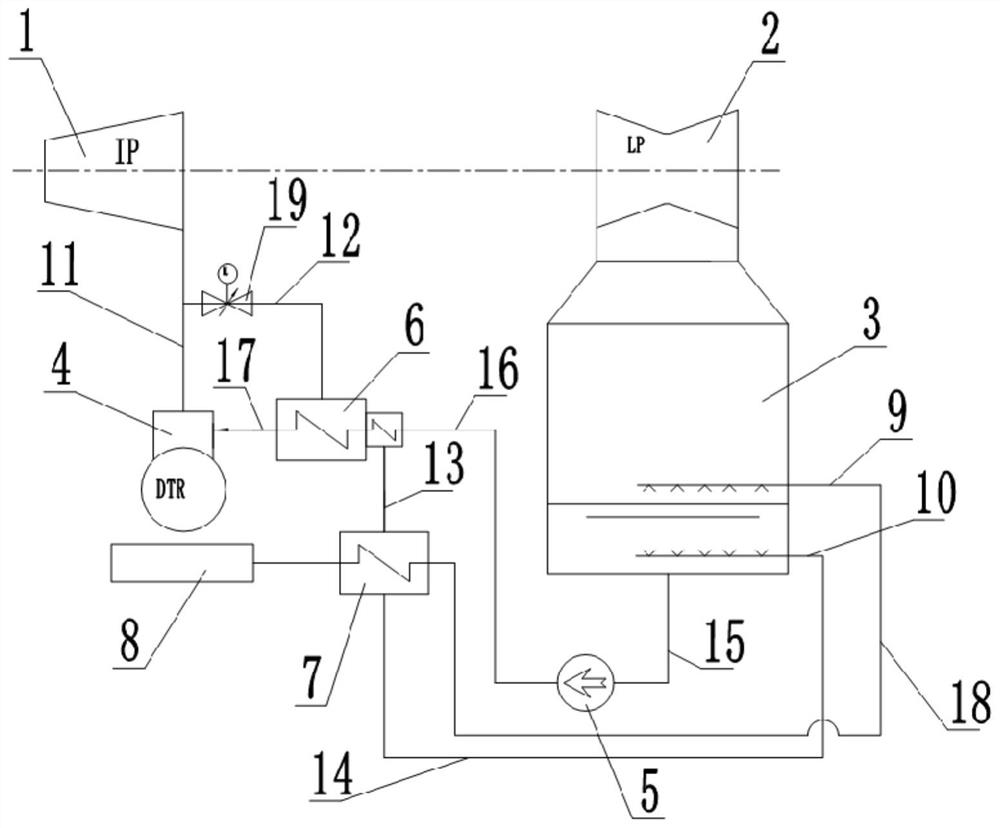

[0033] An industrial water replenishment and oxygen removal system for a low-pressure cylinder cutting unit, such as figure 1 As shown, it includes a low-pressure cylinder 2 and a medium-pressure cylinder 1, the low-pressure cylinder 2 is connected with a condenser 3, the exhaust steam of the medium-pressure cylinder 1 is connected with a deaerator 4, and the deaerator 4 is also connected with a The first heater 6 is connected to the condenser 3, so that the unit can use the condensed water in the condenser 3 to enter the deaerator 4 to exchange heat with steam and enter the Turbine water supply system;

[0034] It also includes an industrial water replenishment system 8, the industrial water replenishment system 8 communicates with a second heater 7, the condenser 3 is provided with a deaeration nozzle assembly 9, and the second heater 7 communicates with the deaeration nozzle assembly 9, The make-up water provided by the industrial make-up water system 8 is used for oxygen ...

Embodiment 2

[0046] An industrial water supplement and deoxygenation method for a low-pressure cylinder with 2 cylinder-cut units, which adopts the industrial water supplement and deoxygenation system for a low-pressure cylinder with 2 cylinder-cut units in Embodiment 1, comprising the following steps:

[0047] a. Under the operating condition of cutting cylinders, the low-pressure cylinder 2 has no exhaust steam, and the exhaust steam of the medium-pressure cylinder 1 provides heating to the deaerator 4 and the first heater 6 through the deaerator pipeline 11 and the steam extraction pipeline 12 respectively. steam;

[0048] b. The condensed water of the hot well of the condenser 3 enters the condensed water pump 5 through the condensed water pipeline 15 of the condenser, and then enters the first heater 6 through the condensed water pipeline 16 after the condensed pump. After the condensed water absorbs the heat of steam extraction, the temperature rises High, and then enter the deaerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com