Oil heater heat dissipation sheet assembly, corresponding hole port welding device and oil heater warmer

A welding device and heat sink technology, applied in welding equipment, roller electrode welding, application, etc., can solve the problems of leakage of oily heat-conducting medium, poor welding quality, and inability to fully guarantee plane sealing, etc., to achieve consistency, Avoid the effect of missing solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

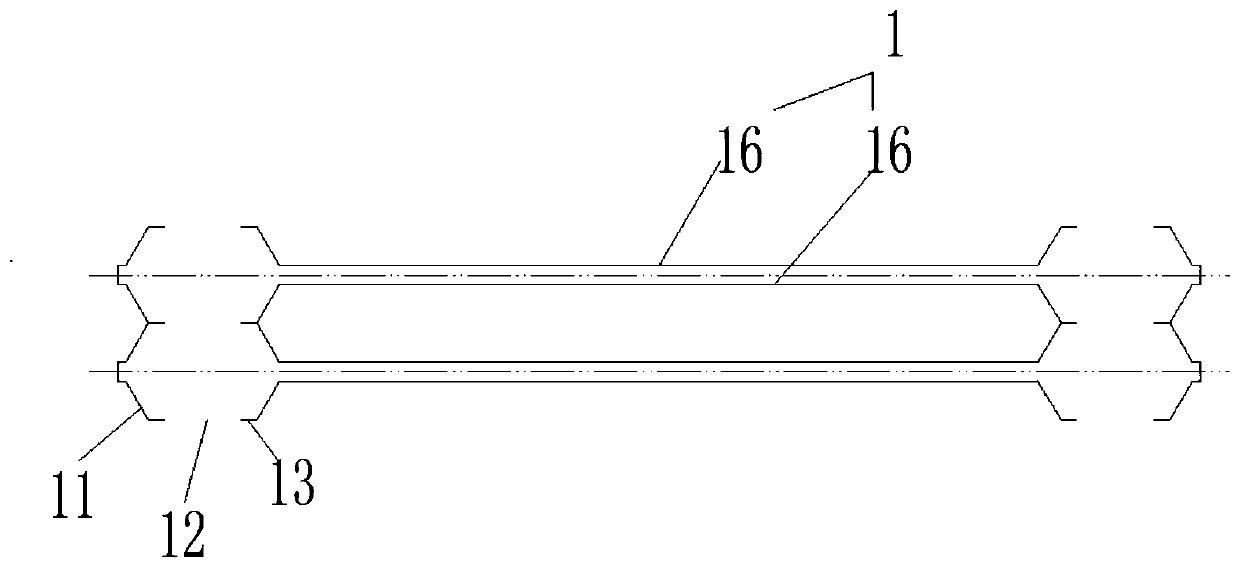

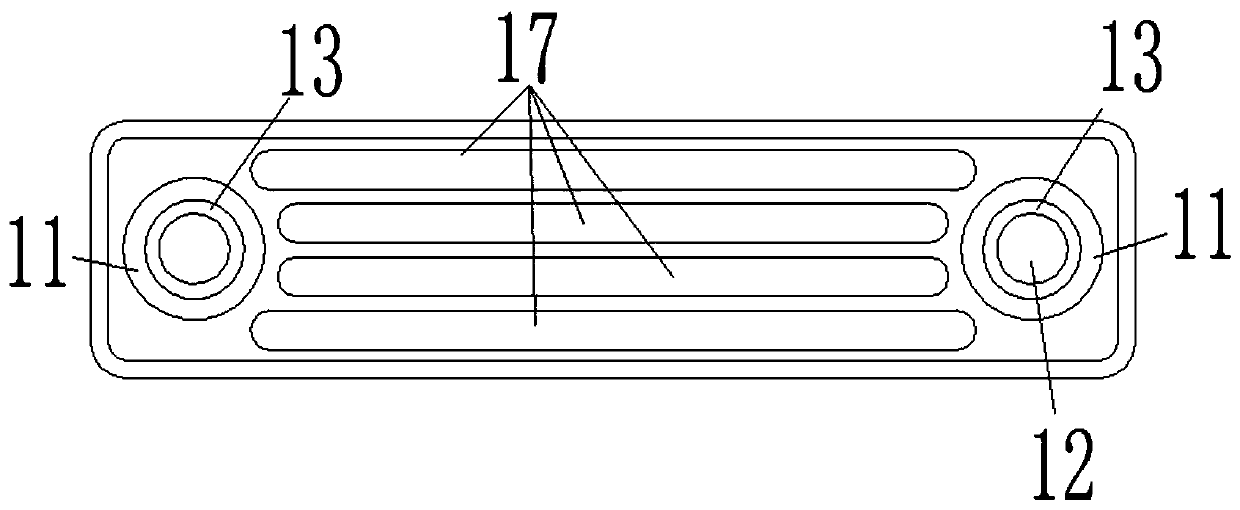

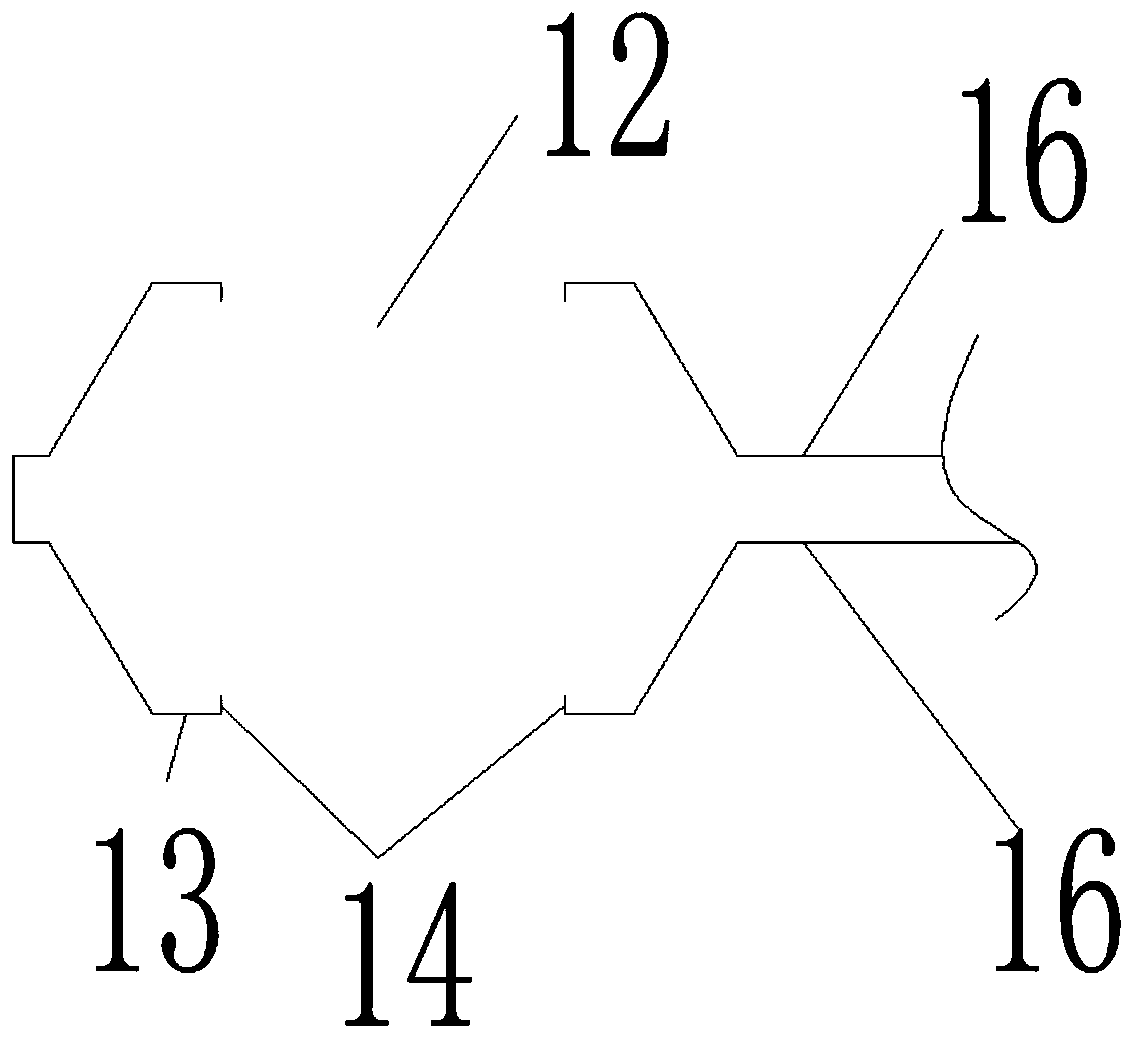

[0022] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present invention, an oil-filled heat sink assembly is provided, which includes two adjacently arranged heat sink assembly monomers 1, and the heat sink assembly monomer 1 has an oil-encased boss 11, so that The oil-included bosses 11 are generally arranged at both ends of the length of the heat-radiating fin assembly monomers 1 as chambers for the circulation of the heat-conducting medium in each of the heat sink assembly monomers 1, and the oil-included bosses 11 have The flow hole 12 passing through along its convex direction, the opening of the flow hole 12 has a ring wall 13 extending radially inward, and the adjacent two fin assembly monomers 1 each have a ring wall 13 They are connected by circumferential seam welding, that is, the two adjacent oil-infused bosses 11 are connected through their respective ring walls 13. It can be understood that for an oil-filled heat sink assemb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap