Tartary buckwheat crisp high-fiber biscuit

A fiber biscuit and crispy technology, which is applied in the field of tartary buckwheat crispy high-fiber biscuits, can solve the problems of low physiological efficacy of dietary fiber, difficulty in meeting consumer demand, and single taste of tartary buckwheat biscuits, so as to enhance human health and utilize physiological activity High degree of effect of reducing the absorption of cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

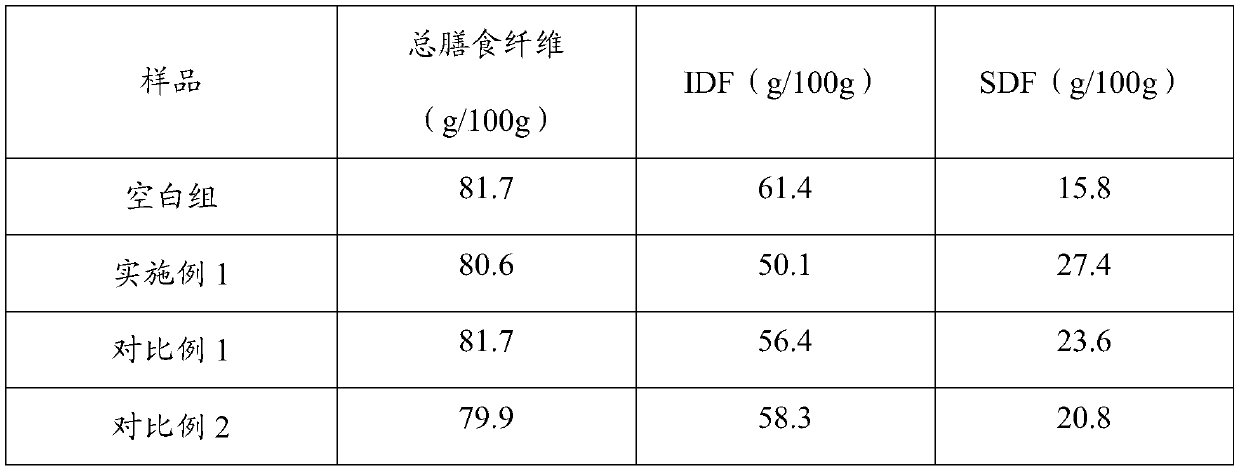

Examples

Embodiment 1

[0039] The modified treatment of tartary buckwheat grains powder, the tartary buckwheat grains powder is combined with steel mill activation-high-pressure cooking, and its process parameters are as follows: the tartary buckwheat grains powder is put into a steel mill and activated at room temperature for 30 minutes to obtain Activated powder: Put the activated powder in a high-pressure sterilizer and treat it at 120°C for 20 minutes, then dry it with hot air to obtain the finished product.

Embodiment 2

[0041] The modified treatment of tartary buckwheat grains powder, the tartary buckwheat grains powder is combined with steel mill activation-high-pressure cooking, and the process parameters are as follows: the tartary buckwheat grains powder is put into a steel mill and activated at room temperature for 60 minutes to obtain Activated powder: Put the activated powder in a high-pressure sterilizer and treat it at 110°C for 90 minutes, then dry it with hot air to obtain the finished product.

Embodiment 3

[0043] The modified treatment of tartary buckwheat grains powder, the tartary buckwheat grains powder is combined with steel mill activation-high-pressure cooking, and the process parameters are as follows: the tartary buckwheat grains powder is put into a steel mill and activated at room temperature for 90 minutes to obtain Activated powder: Put the activated powder in a high-pressure sterilizer and treat it at 100°C for 30 minutes, then dry it with hot air to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com