Full-automatic coconut peeling device

A fully automatic coconut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of easy accidental injury of the operator's hands, high labor intensity, high risk, etc., to achieve beautiful appearance, reduced labor intensity, cutting fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

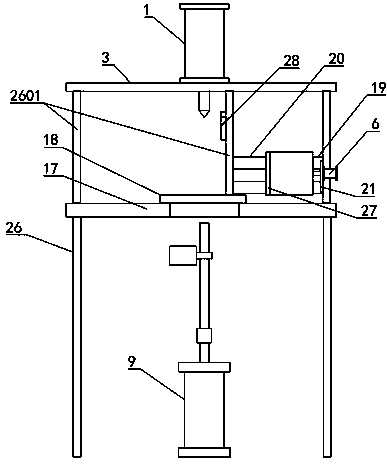

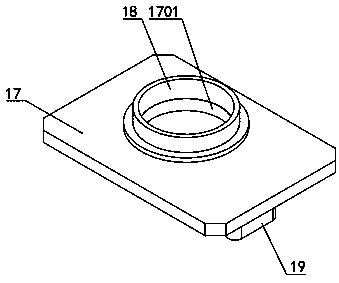

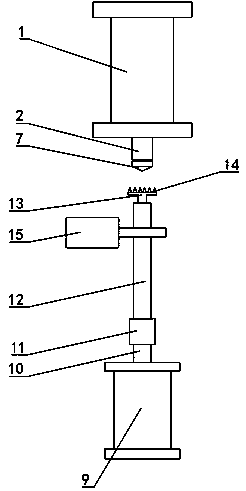

[0028] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0029] Refer to attached Figure 1~7 : a full-automatic coconut peeling device, comprising a frame 26, a clamping device installed on the frame 26 and a cutting device, the top of the frame 26 is provided with a horizontally arranged installation beam 3, and the frame 26 middle part is provided with a horizontally arranged The bearing plate 17, the bearing plate 17 is provided with a vertically set aside through hole 1701, the upper side of the yielding through hole 1701 places coconuts, and the frame 26 between the installation beam 3 and the bearing plate 17 is provided with a cutting device; The clamping device includes a loading device with an upwardly disposed output end and a pressing device with a downwardly disposed output end, and the pressing device is coaxially arranged above the loading device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com