High pressure water-driven auxiliary sludge absorbing device

A technology of high-pressure water and sewage suction chamber, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as unproposed solutions, incomplete cleaning, inconvenient activities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

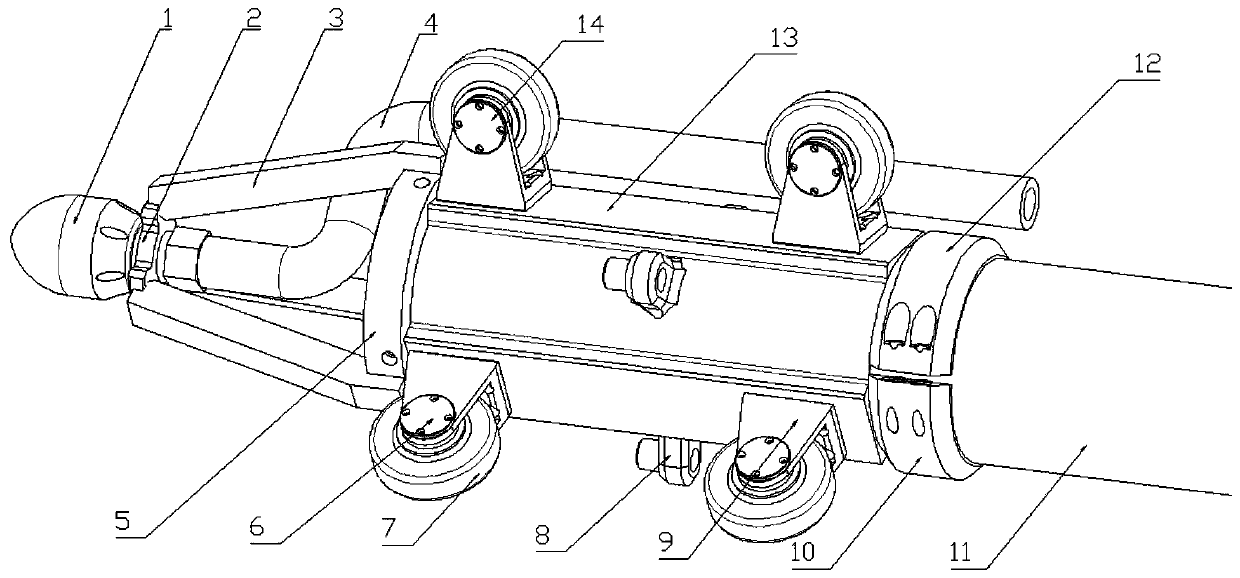

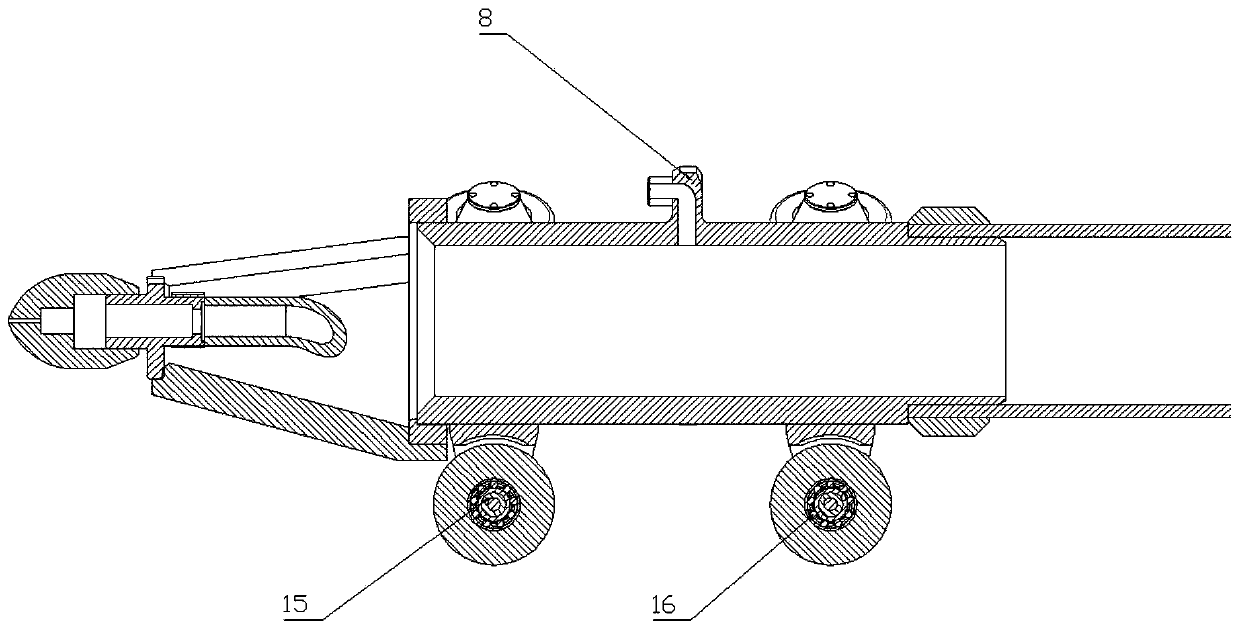

[0020] Such as figure 1 , figure 2 As shown, a high-pressure water-driven auxiliary sewage suction device includes a nozzle 1, a threaded joint 2, a support rod 3, a high-pressure hose 4, an end mounting plate 5, a shaft end cover a6, a roller 7, an air pipe joint 8, and a roller installation plate 9, hoop a10, sewage suction pipe 11, hoop b12, sewage suction cavity 13, shaft end cover b14, shaft 15 and bearing 16; the nozzle 1 is installed at the front end of the threaded joint 2, and the threaded joint 2 and The support rod 3 and the end mounting plate 5 are welded and fixed together, the high-pressure hose 4 is installed at the rear end of the threaded joint 2, and the end mounting plate 5 is mounted on the front end of the suction cavity 13 by bolting. The rotating shaft end cover a6 is fixed on the roller mounting plate 9 by bolts, the roller 7 is installed on the bearing 16, the bearing 16 is installed on the rotating shaft 15, and the rotating shaft 15 is installed on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap