Gear milling machine

A technology for a gear milling machine and a machine body is applied in the field of gear milling machines, which can solve the problems of high production cost, low product quality, and easy damage to the cutter head of the gear milling machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

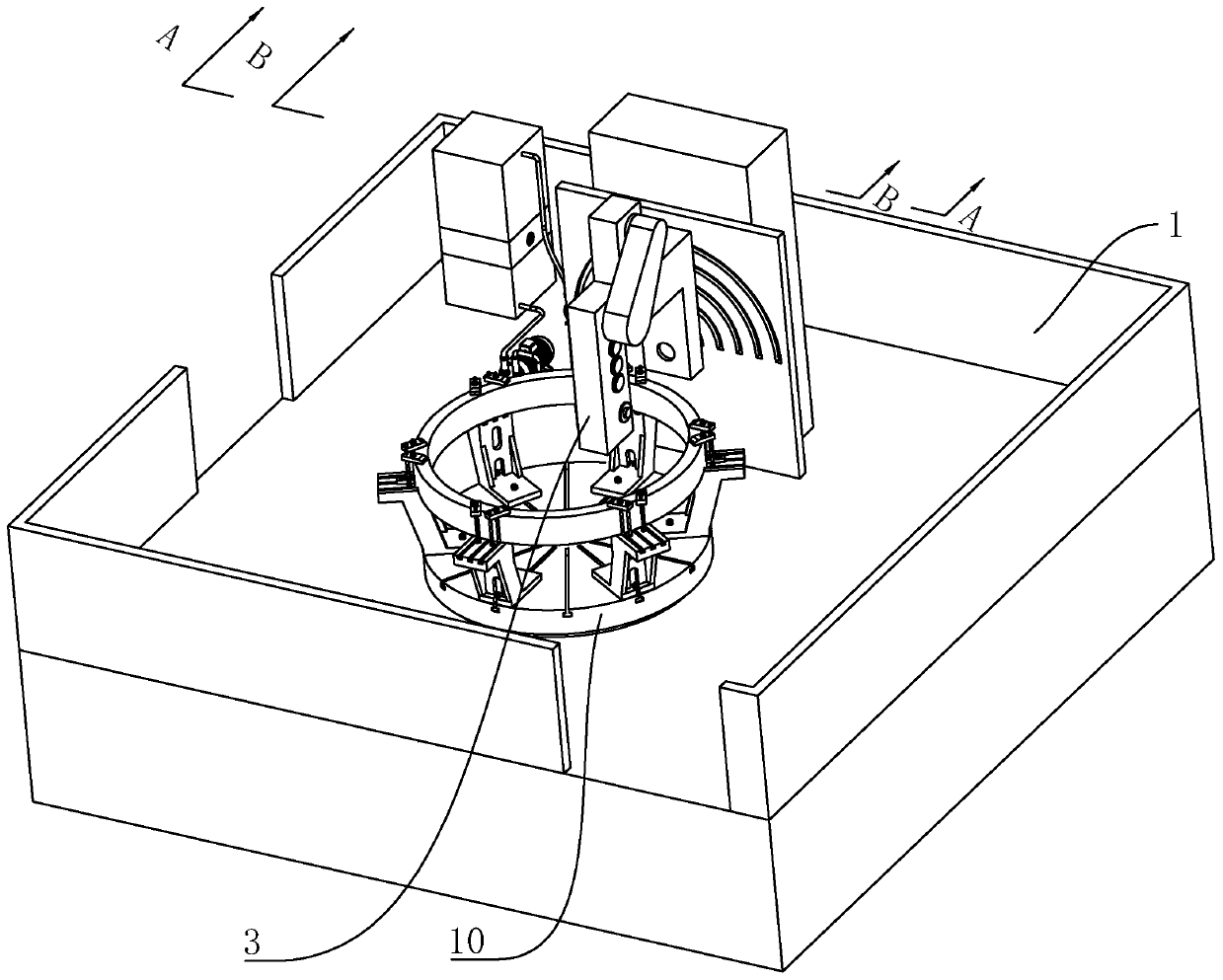

[0068] refer to figure 1 , a gear milling machine, including a body 1, the body 1 is respectively provided with a column 3 and a workbench 10.

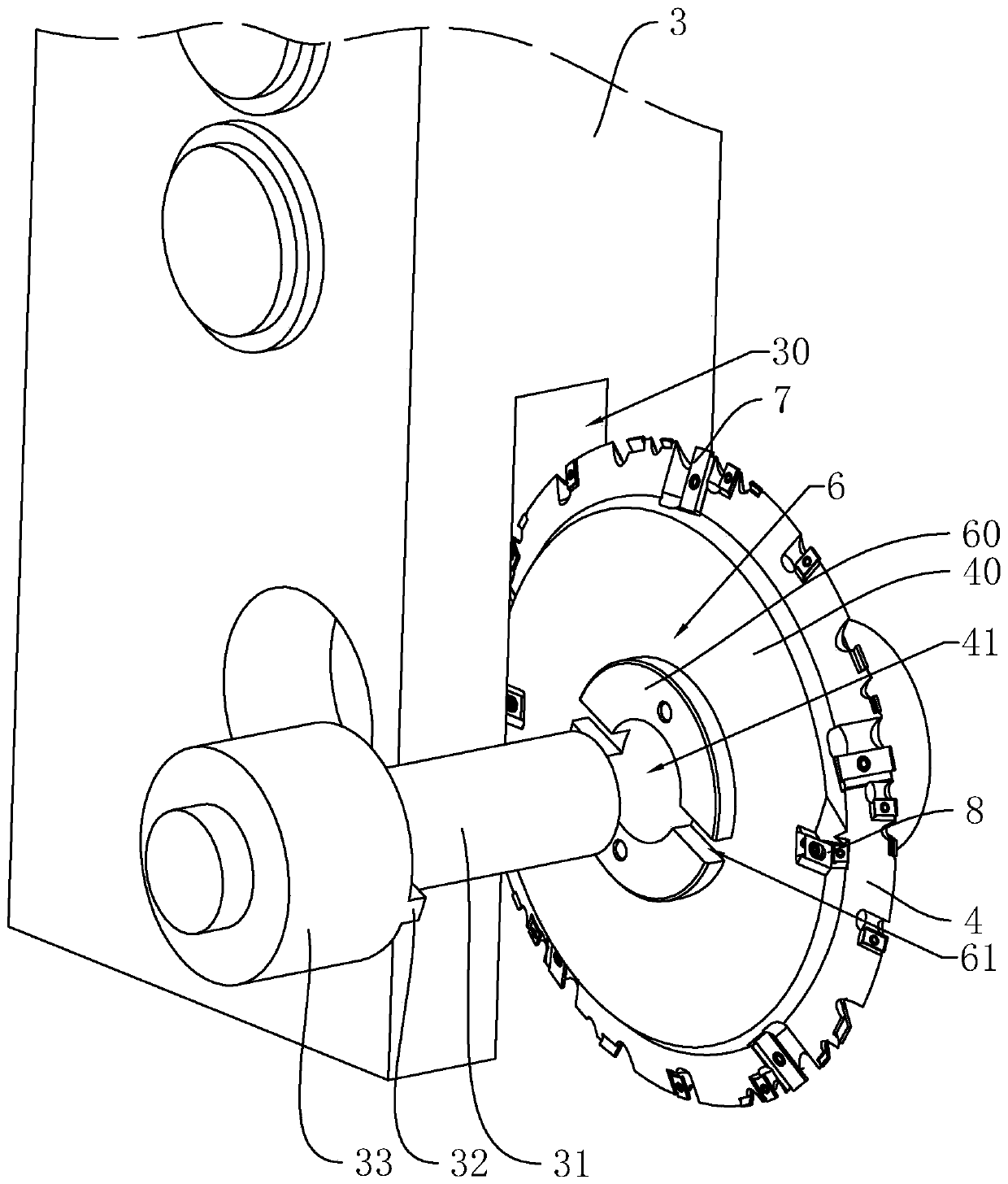

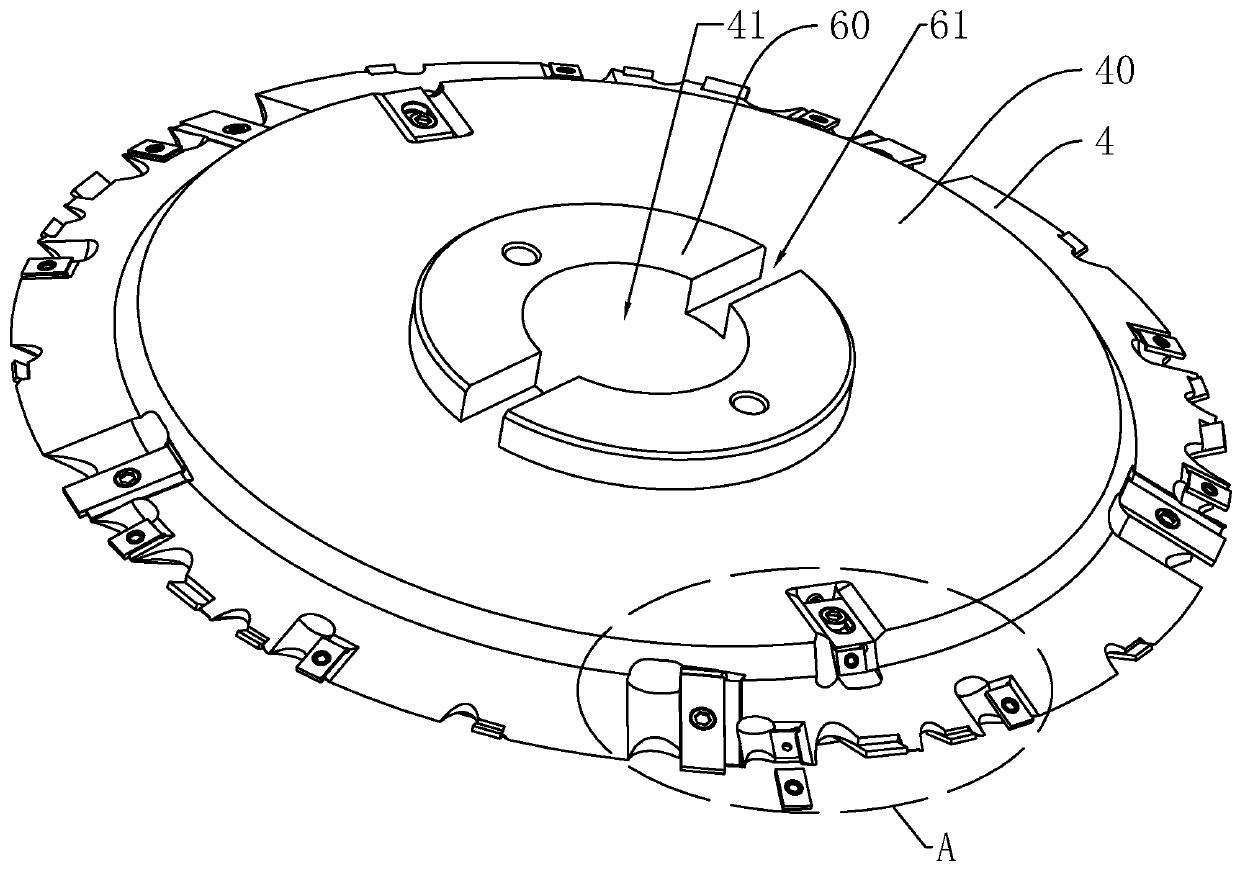

[0069] refer to figure 2 , the bottom wall of the column 3 is provided with a fixed gap 30, the side wall of the fixed gap 30 is rotated with a positioning shaft 31, and the positioning shaft 31 is provided with two fixed sleeves 33, and the fixed sleeve 33 is fixedly connected with the positioning shaft 31. Two protrusions 32 are arranged on the opposite side walls of the fixed sleeve 33, and a cutter body 4 is fixedly arranged on the side wall of the positioning shaft 31. Bosses 40 are arranged on opposite sides of the cutter body 4, and the diameter of the bosses 40 is Less than the diameter of the cutter body 4, the side wall of the boss 40 is provided with a mounting hole 41 for the positioning shaft 31 to pass through, and the side of the boss 40 away from the cutter body 4 is provided with two half ring plates 60, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com