Top-mounted environment friendly mixing plant stock bin distribution structure

A kind of mixing building, environmental protection technology, applied in the field of top-mounted environment-friendly mixing building silo distribution structure, can solve the problems of complex structure of mixing building, low space utilization rate, etc., to improve the production environment, improve efficiency, occupy an area small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

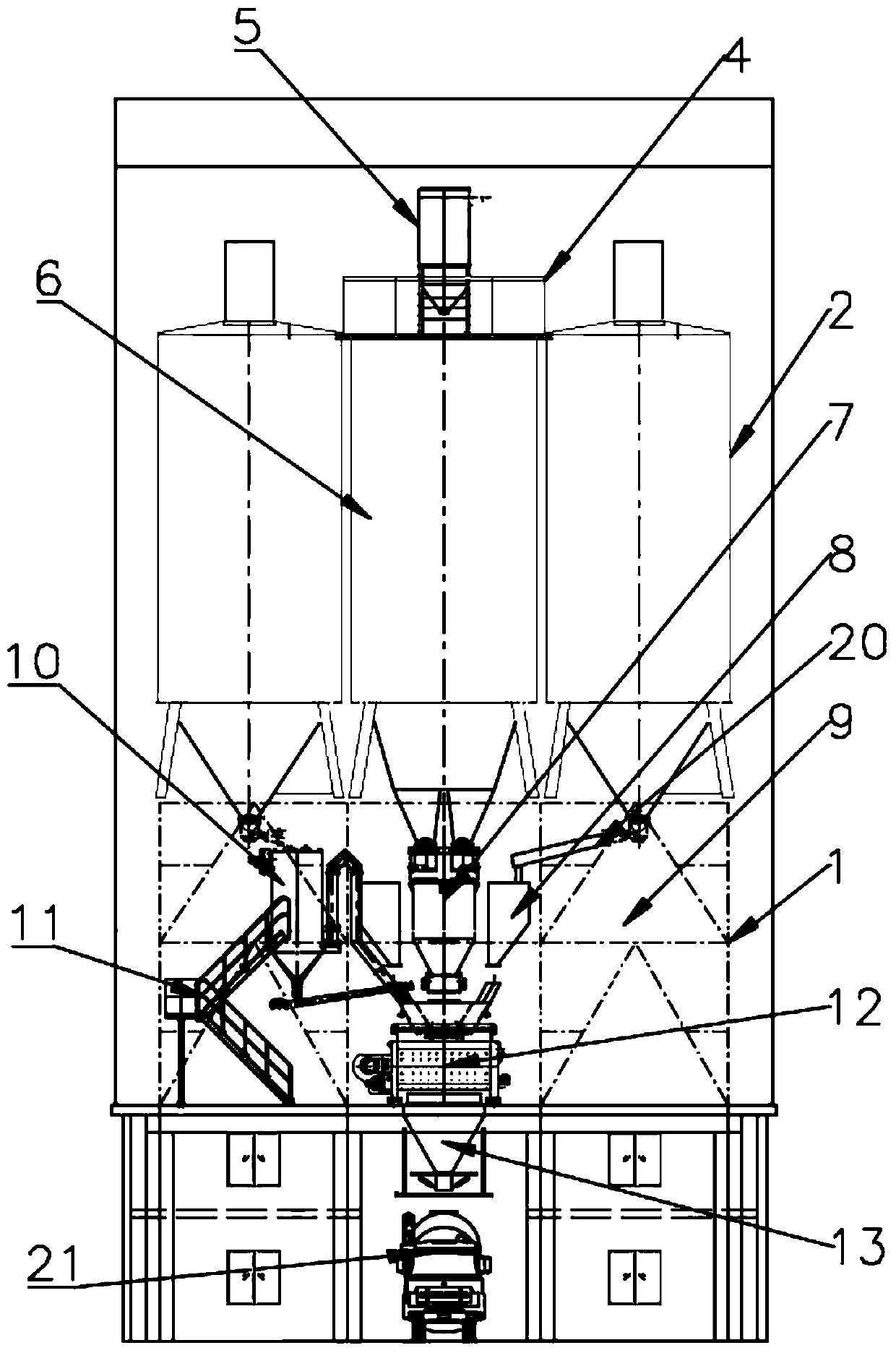

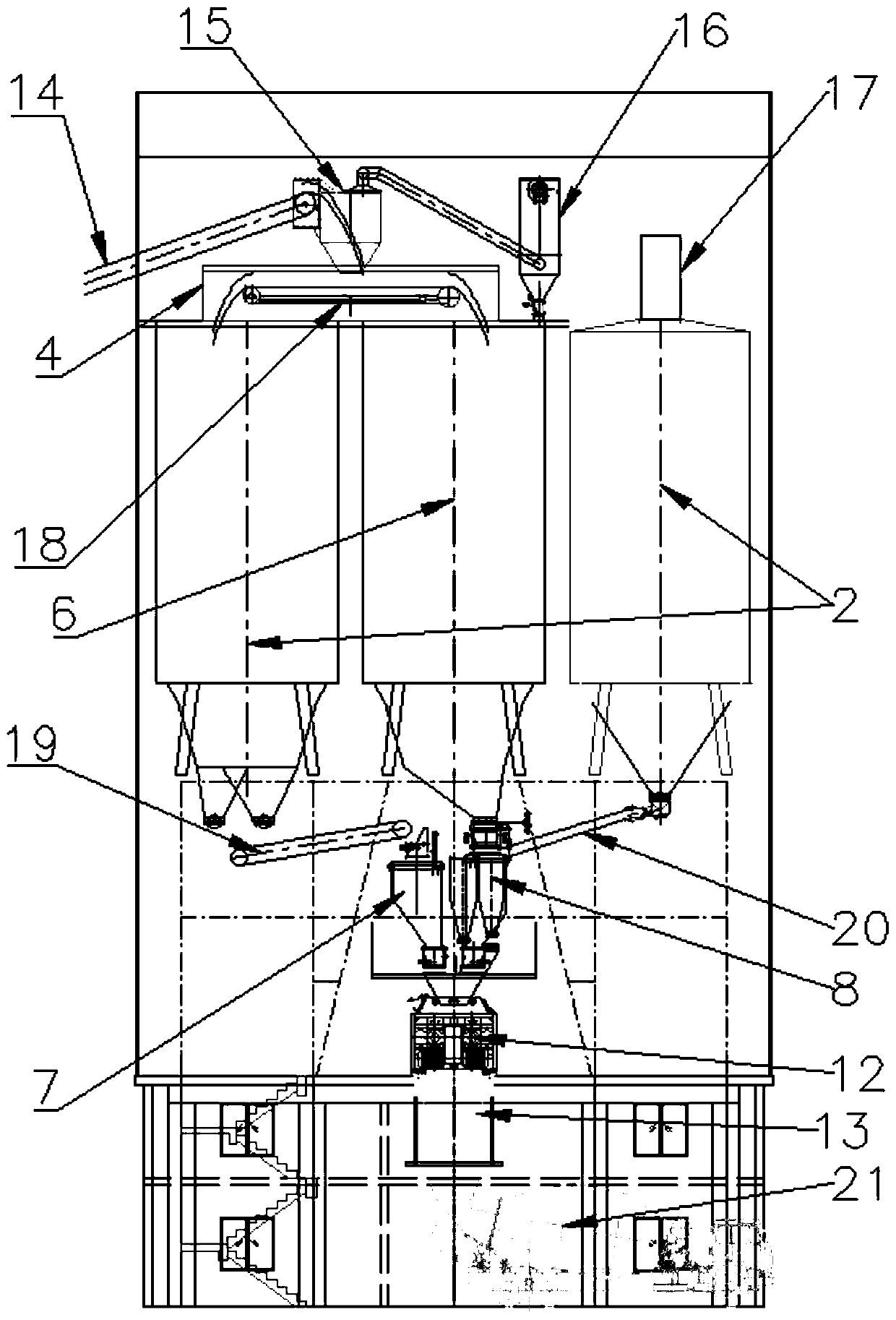

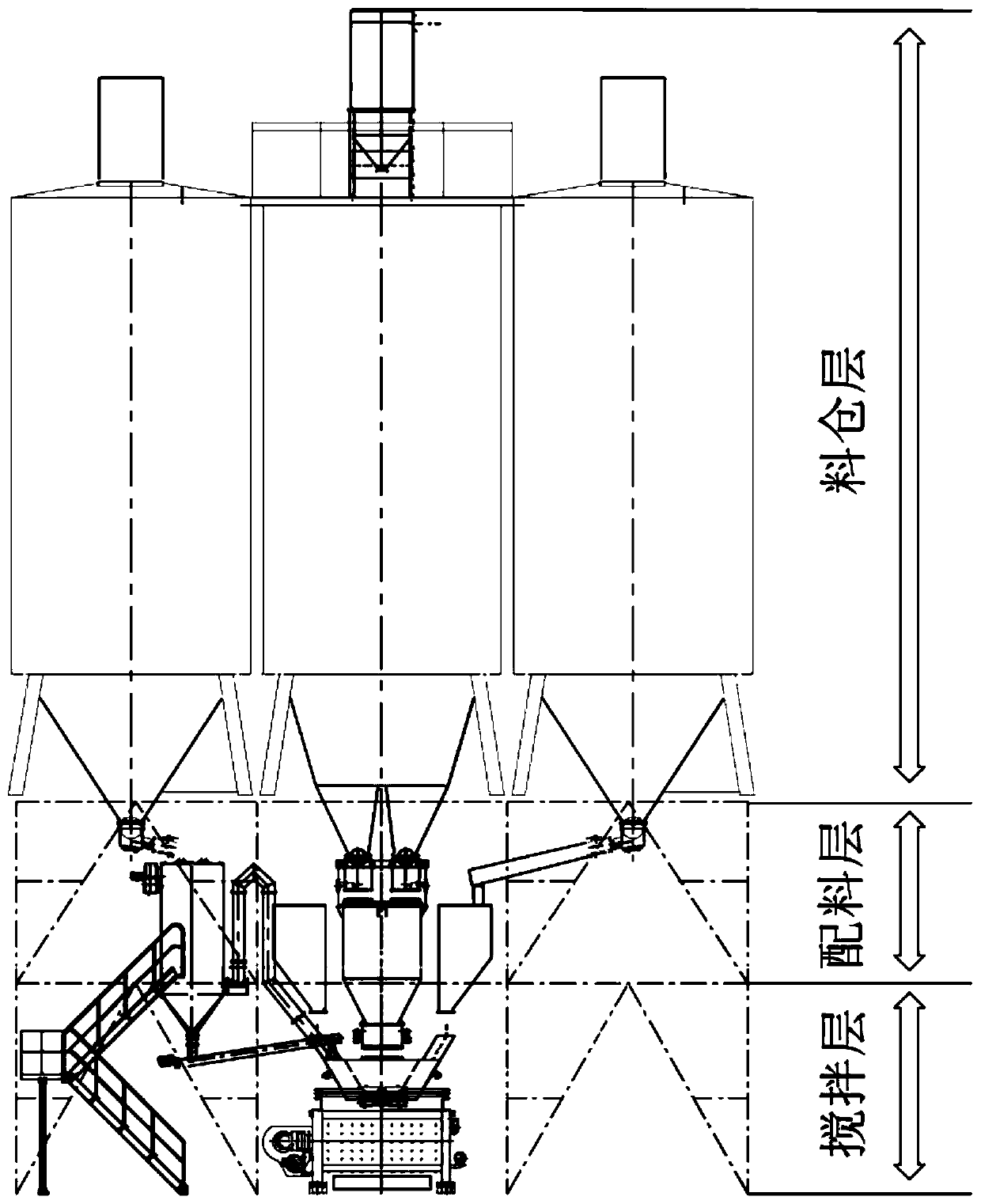

[0048] like figure 1 As shown in the figure, a top-type environment-friendly mixing building silo distribution structure includes an integrated frame 1, and the integrated frame 1 is an H-shaped steel or a rectangular steel pipe or a circular steel pipe structure, which is used to fix the internal components of the integrated frame 1. The top of the integrated frame 1 is provided with a silo layer, the middle part is provided with an ingredient layer, and the lower part is provided with a stirring layer; wherein the top silo layer of the integrated frame 1 includes a powder silo 2 and an aggregate silo 6, and the top of the powder silo 2 is provided with The silo top pulse dust collector 17 can effectively prevent dust from being generated when the top of the powder silo 2 is filled. The top of the silo is also provided with a material distribution belt conveyor 18, and the material distribution belt conveyor 18 can transfer the feeding belt conveyor 14 to the transition hopper...

Embodiment 2

[0051] In this embodiment, the structure of the silo layer, the batching layer and the stirring layer of the mixing building are the same as those in Embodiment 1, such as Figure 5 As shown, the arrangement of the silos is a rectangular uniform arrangement, wherein the shape of the powder silos 2 and the aggregate silos 6 are cylindrical and the same or similar in size, the number of the silos is S, and the size of the powder silos is S. The quantity is N, the quantity of the aggregate bin or the sand and gravel bin is M, where S is 9, N is 7, M is 2, and the legs of the water tank 22 are connected to the bin body or the legs as a support, Interspersed in the neutral position of the aggregate bin 6 and the powder bin 2, no separate support is required, the structure is simplified, the space is saved, and the cost is saved.

[0052] In this embodiment, the multi-row and multi-column silos are arranged in a semi-enclosed structure, with an aggregate silo or a gravel silo in the...

Embodiment 3

[0054] In this embodiment, the structure of the silo layer, the batching layer and the stirring layer of the mixing building are the same as those in Embodiment 1, such as Image 6 As shown, the arrangement of the silos is a rectangular uniform arrangement, wherein the shape of the powder silos 2 and the aggregate silos 6 are cylindrical and the size is the same or close, the number of the silos is S, and the size of the powder silos is S. The number is N, the number of the aggregate bin or the sand and gravel bin is M, where S is 6, N is 5, M is 1, and the legs of the water tank 22 are connected to the bin body or the legs as a support, Interspersed in the neutral position of the aggregate bin 6 and the powder bin 2, no separate support is required, the structure is simplified, the space is saved, and the cost is saved.

[0055] In this embodiment, the multi-row and multi-column silos are arranged in a semi-enclosed structure, with an aggregate silo or a gravel silo in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com