A kind of composite protective material and preparation method thereof for new crown pneumonia epidemic prevention

A protective material and pneumonia technology, which is applied in the field of composite protective materials for new coronary pneumonia epidemic prevention and its preparation, can solve the problems of the mechanical properties, air permeability and comfort of polyester fabrics, and affect the wearing performance of fiber fabrics, etc., and achieve excellent antibacterial, The effect of increasing the load and improving the air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

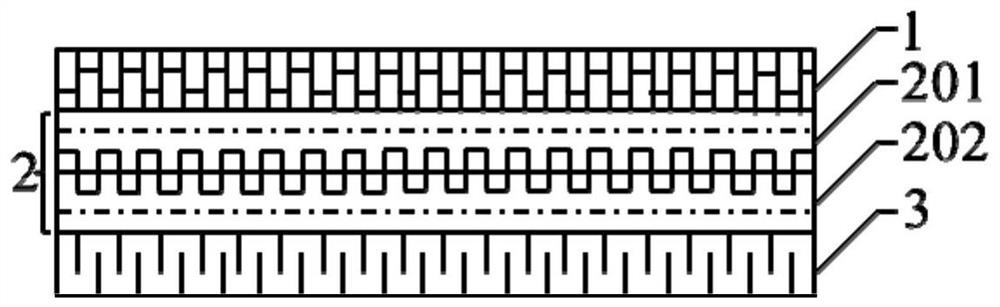

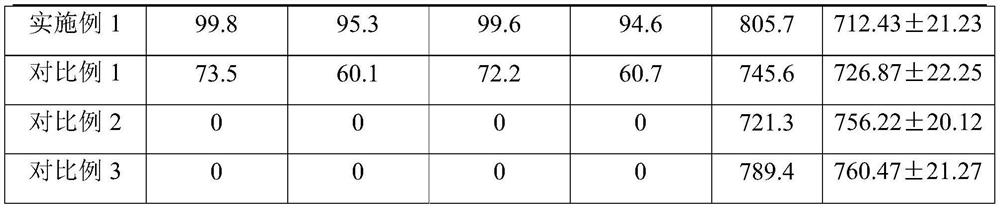

[0063] A composite protective material for the prevention of new coronary pneumonia, including a support layer, a nanofiber antibacterial layer and a skin-friendly layer arranged sequentially from the outside to the inside, the nanofiber antibacterial layer includes a layer loaded with hexamethylene diisocyanate modified The hydroxyl-terminated hyperbranched polyester nanofiber nonwoven fabric of graphene and the carboxyl-terminated hyperbranched polyester nanofiber nonwoven fabric loaded with diethylenetriamine-modified graphene are prepared by the following steps:

[0064] S1. Preparation of hydroxyl-terminated hyperbranched polyester nanofiber nonwoven fabric

[0065] The hydroxyl-terminated hyperbranched polyester masterbatch and cellulose acetate butyrate with a mass ratio of 1:8 are melt-extruded through a twin-screw extruder, drawn, and laid into a network to obtain a hydroxyl-terminated hyperbranched polyester / acetate butyrate Cellulose blended fiber non-woven fabric; ...

Embodiment 2-3 and comparative example 4-5

[0103] Compared with Example 1, the composite protective materials provided in Examples 2-3 and Comparative Examples 4-5 for the prevention of new coronary pneumonia are different in that in step S1, the softening point is at a high degree of branching at 100°C Mass ratio m 1 :m 2 As shown in Table 2, the others are basically the same as those in Embodiment 1, and will not be repeated here.

[0104] The test result of table 2 embodiment 2-3 and comparative example 4-5

[0105]

[0106] It can be seen from Table 2 that with the increase in the mass ratio of the high-branched hydroxyl-terminated hyperbranched polyester masterbatch with a softening point of 100°C and the low-branched hydroxyl-terminated hyperbranched polyester masterbatch with a softening point of 200°C The antibacterial rate of the protective material and the antibacterial rate after washing gradually increased, but the breaking strength and air permeability both increased first and then decreased. This is...

Embodiment 4-5 and comparative example 6-7

[0108] Compared with Example 1, the composite protective materials provided in Examples 4-5 and Comparative Examples 6-7 for the prevention of new coronary pneumonia are different in that in step S2, the softening point is at a high degree of branching at 100°C The mass ratio m 3 :m 4 As shown in Table 3, the others are basically the same as those in Embodiment 1, and will not be repeated here.

[0109] The test result of table 3 embodiment 4-5 and comparative example 6-7

[0110]

[0111] As can be seen from Table 3, with the softening point at 100 ° C high degree of branching carboxyl hyperbranched polyester masterbatch and softening point at 200 ° C low branching carboxyl hyperbranched polyester masterbatch mass ratio Increase, the antibacterial rate of the protective material and the antibacterial rate after washing all gradually increase, but the breaking strength and air permeability all increase first and then decrease, and the impact mechanism is roughly the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com