Textile machine yarn guide device

A mechanical guide and textile technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of inability to adjust the yarn relaxation, low efficiency, poor quality, etc., to facilitate suction and collection , High dust removal efficiency and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

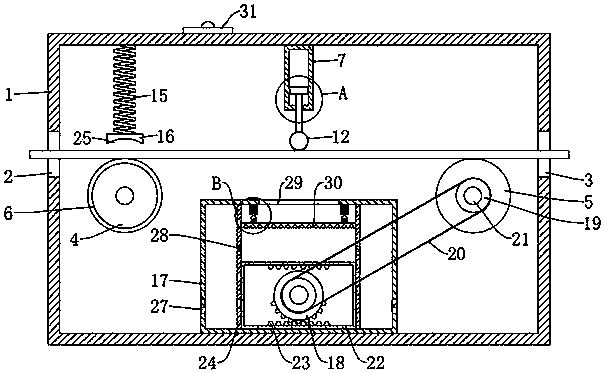

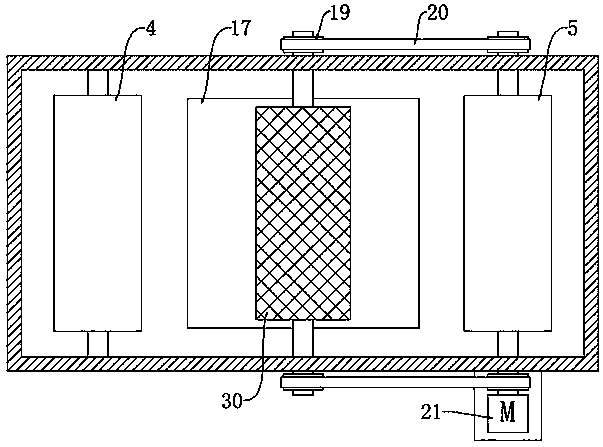

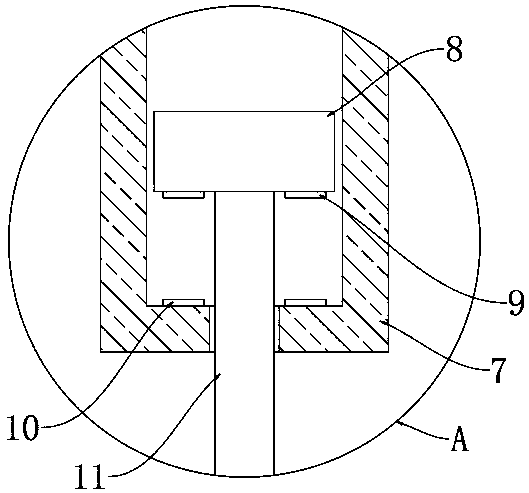

[0029] refer to Figure 1-5 , a yarn guiding device for a textile machine, comprising a box body 1, a yarn inlet 2 and a yarn outlet 3 are symmetrically opened on the box body 1, and an adjusting roller 4 and a yarn guiding roller 5 are installed in the box body 1 for symmetrical rotation, and the adjusting roller 4. The outer fixing sleeve is provided with a ferromagnetic ring 6, and the horizontal line between the upper end surface of the adjustment roller 4 and the guide roller 5 is located at the center point of the yarn inlet 2 and the yarn outlet 3, and a limit cylinder is fixedly installed on the inner top wall of the box body 1. 7. A slider 8 is slidably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com