A copper twisting machine with a pay-off device

The technology of a pay-off device and a wire take-up mechanism is applied in the directions of transportation and packaging, processing of thin materials, and transportation of filamentous materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

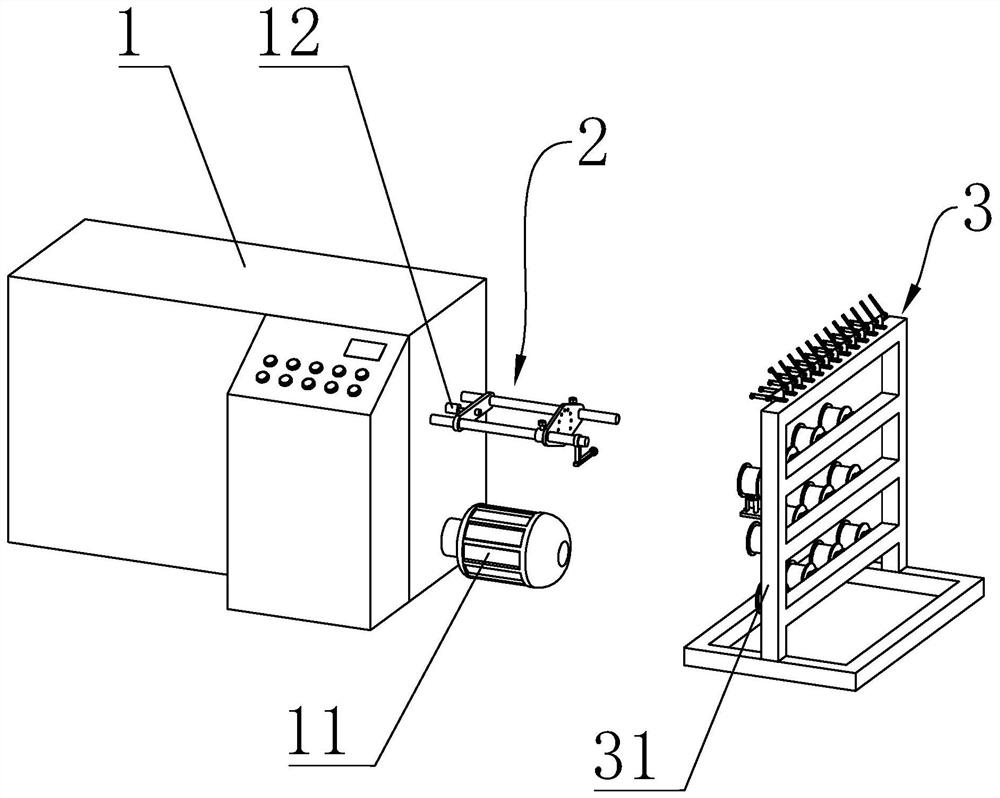

[0034] Example: refer to figure 1 , is a kind of copper wringer with pay-off device disclosed by the present invention, comprising a copper wrench body 1 and a wire pay-off device 3 arranged on one side of the copper wrench body 1, and a motor 11 arranged on the copper wrench body 1 , The main body 1 of the copper twisting machine is provided with a take-up mechanism 2 along the horizontal direction.

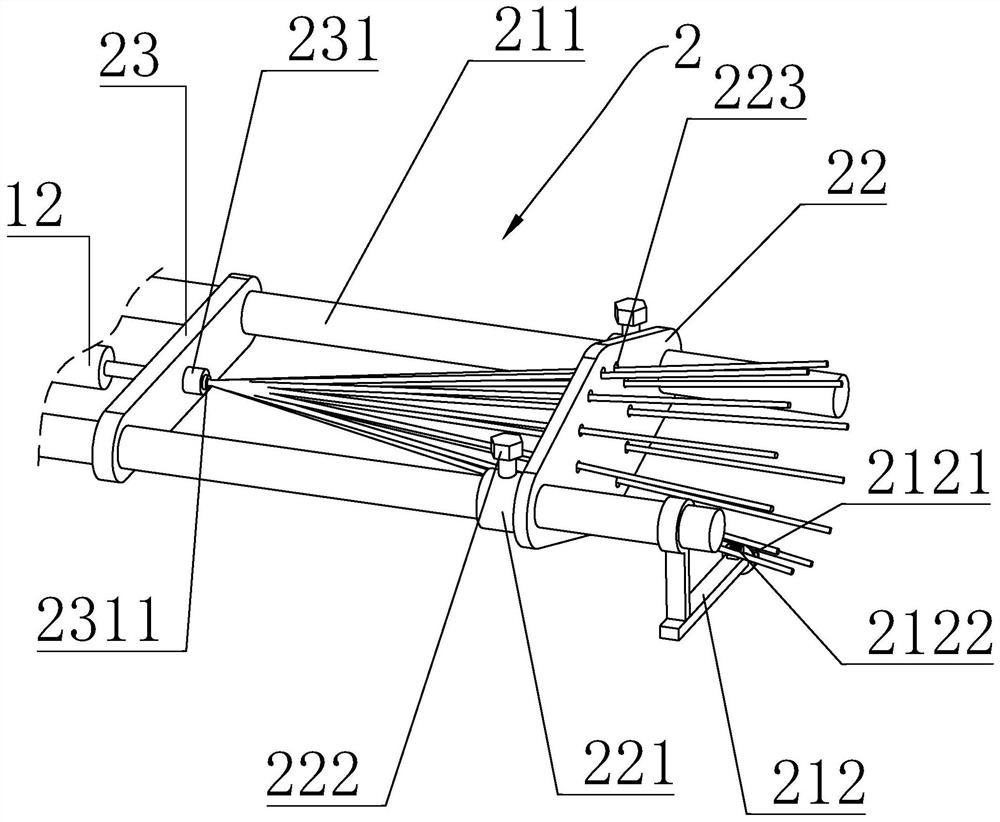

[0035] refer to figure 2 The take-up mechanism 2 includes a take-up frame 21 arranged in the horizontal direction, the take-up stand 21 is two parallel take-up rods 211, one end of the take-up rod 211 is welded on the outside of the copper winch body 1, and the take-up rod 211 The upper slide is connected with a distribution board 22, and a collar 221 is fixedly connected to the distribution board 22. The collar 221 is sleeved on the take-up rod 211. The fastening bolt 222 on the rod 211. The operator can slide the distribution plate 22 along the take-up rod 211 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com