Apple flavor compound, preparation method thereof and food additive

A compound and flavor technology, applied in the field of spices, can solve the problems of limited types and low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

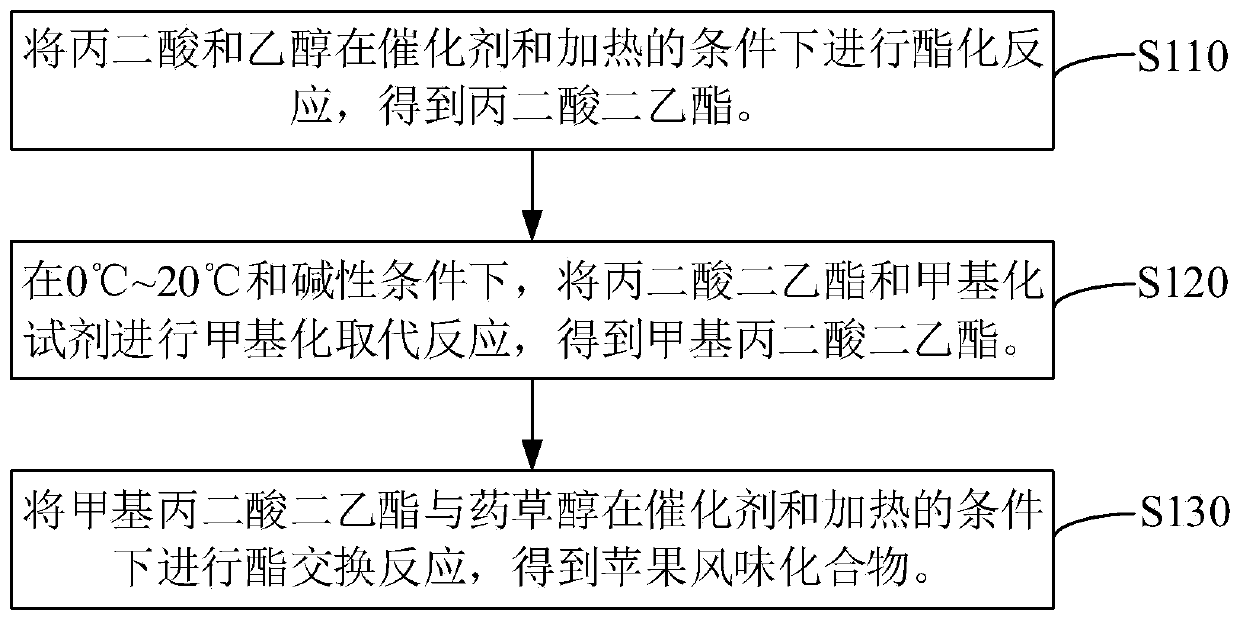

[0025] see figure 1 , the preparation method of the apple flavor compound of one embodiment, comprises the steps:

[0026] Step S110: Esterifying malonic acid and ethanol under the conditions of catalyst and heating to obtain diethyl malonate.

[0027] In one embodiment, the catalyst is p-toluenesulfonic acid. It can be understood that in other embodiments, the catalyst can also be other catalysts, such as acid catalysts such as concentrated sulfuric acid or basic catalysts such as sodium hydroxide. In the step of the esterification reaction, the reaction temperature is 78° C., and the reaction time is 4 hours.

[0028] Specifically, the reaction process of step S110 is as follows:

[0029]

[0030] In one of the examples, step S110 is: heating malonic acid and ethanol at 78°C and catalyzed by p-toluenesulfonic acid, performing esterification reaction for 4 hours, and distilling under reduced pressure after the reaction to obtain diethyl malonate ester. It should be no...

Embodiment 1

[0060] The preparation process of the apple flavor compound of the present embodiment is specifically as follows:

[0061] (1) preparation of diethyl malonate:

[0062]

[0063] Add malonic acid (210g), absolute ethanol (460g) and p-toluenesulfonic acid (2g) into 1L reactor, then heat up to 78°C, stir and react for 4 hours, then distill under reduced pressure to obtain diethyl malonate Esters (215g).

[0064] (2) preparation of diethyl methylmalonate:

[0065]

[0066] Add benzene (500mL), diethyl malonate (215g), dimethyl sulfate (330g) and TEBA (322g) to a 1L reactor in sequence, then cool to 0°C and stir at a speed of 400r / min. Slowly add a mass concentration of 44% sodium hydroxide aqueous solution (172g), during the dropwise addition, the reaction temperature is not more than 20°C, and the dropwise addition is completed in about 1 hour, and then continue to stir and react at 15°C for 4 hours. After the reaction was completed, the layers were placed to obtain an u...

Embodiment 2

[0078] The preparation process of the apple flavor compound of the present embodiment is specifically as follows:

[0079] (1) preparation of diethyl malonate:

[0080] Add malonic acid (210g), absolute ethanol (460g) and p-toluenesulfonic acid (2g) in 1L reactor, then raise the temperature to 78°C, stir and react for 4 hours, then distill under reduced pressure to obtain diethyl malonate Esters (215g).

[0081] (2) preparation of diethyl methylmalonate:

[0082] Add benzene (500mL), diethyl malonate (215g), dimethyl sulfate (330g) and TEBA (322g) to a 1L reactor in sequence, then cool to 15°C and stir at 400r / min. Slowly add a mass concentration of 44% sodium hydroxide aqueous solution (172g), during the dropwise addition, the reaction temperature is not more than 20°C, and the dropwise addition is completed in about 1 hour, and then continue to stir and react at 15°C for 5 hours. After the reaction was completed, the layers were placed to obtain an upper organic phase and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com