Production process of bovine collagen peptides

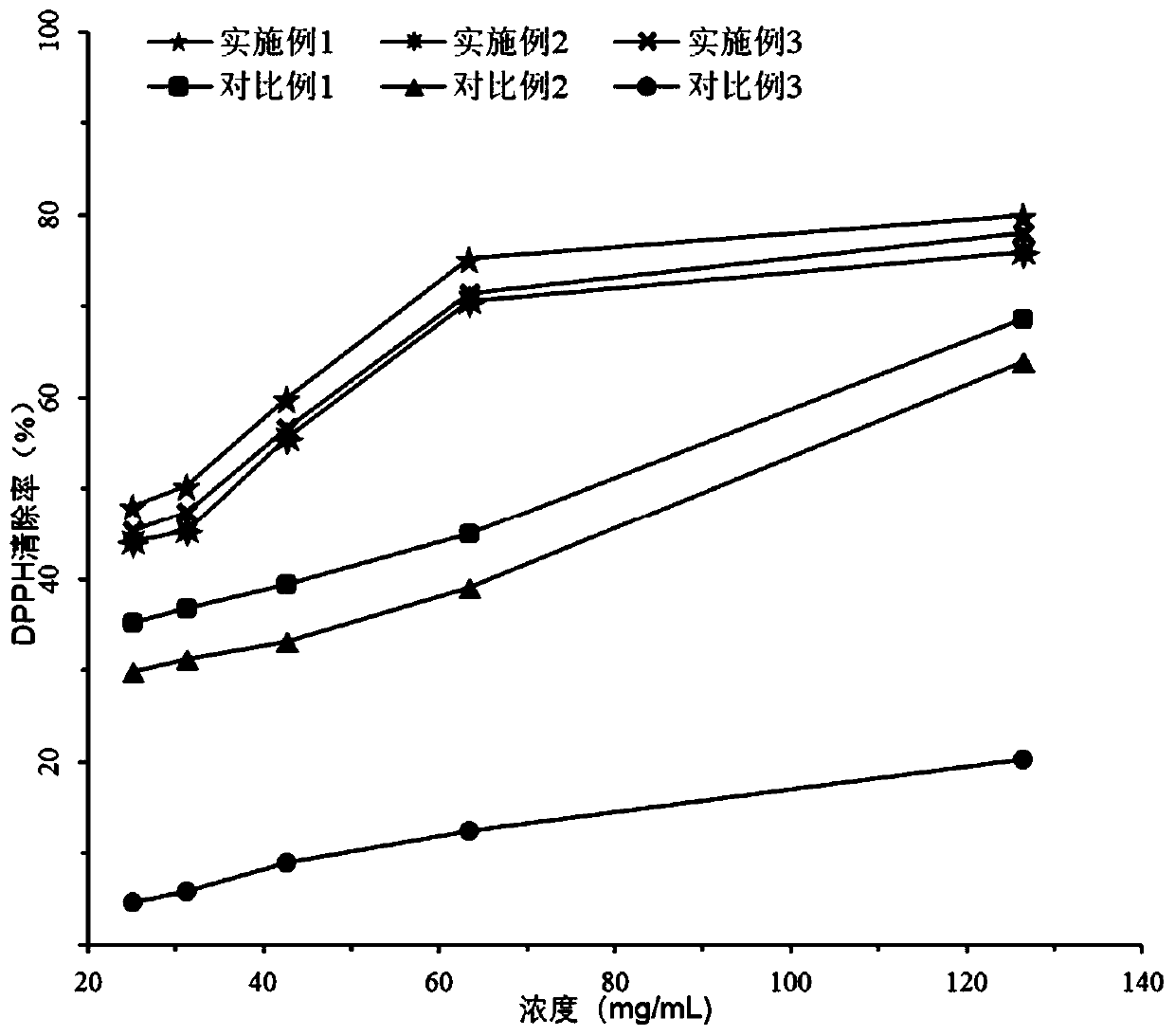

A production process and original protein technology, which is applied in the production process of cowhide collagen peptides, can solve the problems of irreversible loss of products, unpleasant sensory perception, deepening of product color, etc., achieve high biological antioxidant activity, avoid loss of protein peptides, The effect of reducing the quality difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of production technology of cowhide collagen protein peptide, comprises the following steps:

[0040] S1 Cleaning: Wash 100 parts of cowhide with water, immerse the cleaned cowhide in 1400 parts of water, add NaOH to adjust the pH value to 13, add 1.35 parts of H 2 o 2 , soak for 78 hours;

[0041] S2 Denaturation: Wash the clean cowhide obtained in step S1 until the pH is neutral, then cut and grind it to make a cowhide slurry, add water 5 times the mass fraction of the cowhide slurry to the cowhide slurry, and set the heat preservation temperature during denaturation to 72°C, the holding time is set to 5.5h, and the denatured cowhide protein slurry is obtained;

[0042] S3 Enzymolysis: Add 3.75 parts of alkaline protease to the denatured cowhide protein slurry obtained in step S2 denaturation, keep the temperature at 57°C, keep the pH at 8.2, and react for 5.5 hours. The power is 700kW, and finally the enzymolysis solution is obtained;

[0043] S4 centrifug...

Embodiment 2

[0048] A kind of production technology of cowhide collagen protein peptide, comprises the following steps:

[0049] S1 Cleaning: Wash 100 parts of cowhide with water, immerse the cleaned cowhide in 1000 parts of water, add NaOH and NaOH 2 CO 3 Adjust the pH value to 10, add 2 parts of stable chlorine dioxide, and soak for 50 hours;

[0050] S2 Denaturation: Wash the clean cowhide obtained in step S1 until the pH is neutral, then cut and grind it to make a cowhide slurry, add water 4 times the mass fraction of the cowhide slurry to the cowhide slurry, and set the heat preservation temperature during denaturation to 60-80°C, the holding time is set to 6h, and the denatured cowhide protein slurry is obtained;

[0051] S3 Enzymolysis: Add 2 parts of alkaline protease to the denatured bovine skin protein slurry obtained in step S2 denaturation, keep the temperature at 65°C, keep the pH at 7.5, and react for 6 hours. The power is 300kW, and finally the enzymatic hydrolysis soluti...

Embodiment 3

[0057] A kind of production technology of cowhide collagen protein peptide, comprises the following steps:

[0058] S1 Cleaning: Wash 100 parts of cowhide with water, immerse the cleaned cowhide in 2000 parts of water, add NaOH and CaO to adjust the pH value to 14, add 0.5 part of sodium hypochlorite, and soak for 200 hours;

[0059] S2 Denaturation: Wash the clean cowhide obtained in step S1 until the pH is neutral, then cut and grind it to make a cowhide slurry, add 6 times the mass fraction of the cowhide slurry to the cowhide slurry, and set the heat preservation temperature during denaturation to 80°C, the holding time is set to 4h, and the denatured bovine hide protein slurry is obtained;

[0060] S3 Enzymolysis: Add 5 parts of alkaline protease to the denatured cowhide protein slurry obtained in step S2 denaturation, keep the temperature at 50°C, keep the pH at 9.5, and react for 5 hours. Use ultrasonic-assisted enzymolysis during the enzymolysis process. The power is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com